Rapid drying and calcination method for honeycomb denitration catalyst

A denitration catalyst and rapid drying technology, which can be used in chemical instruments and methods, catalyst activation/preparation, physical/chemical process catalysts, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

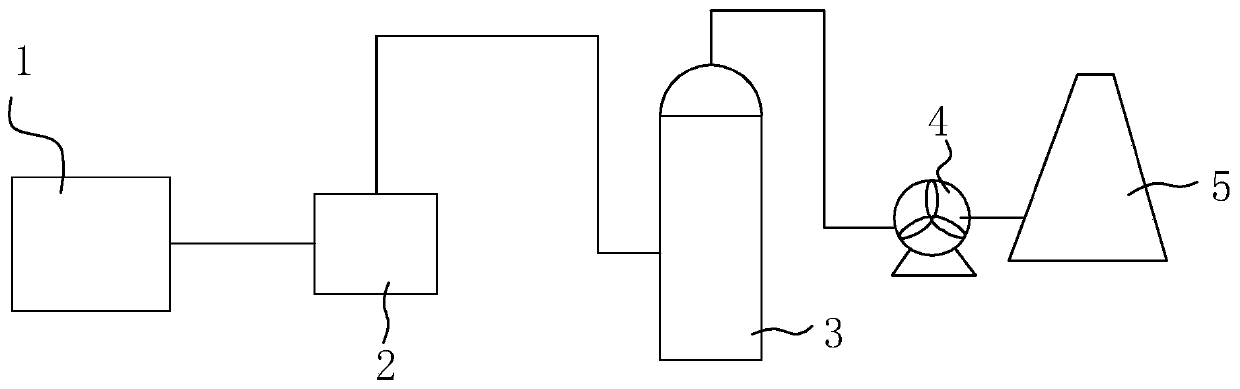

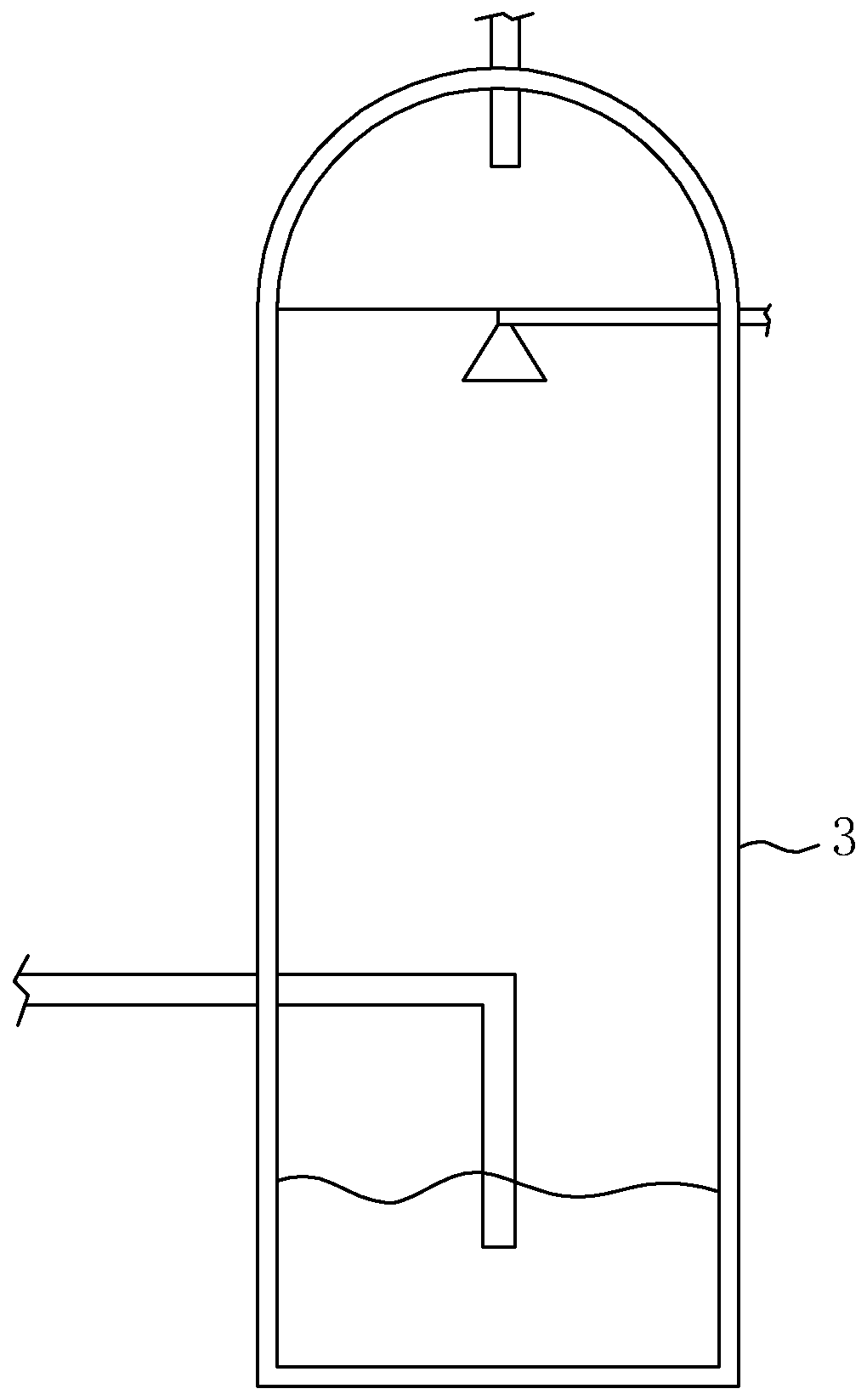

[0039] A honeycomb type denitration catalyst rapid drying and calcination method, comprising the following steps:

[0040] Step 1: Pack the extruded 150×150×300mm, 18*18-hole catalyst wet embryo in a carton called sponge and put it on a plastic board with a porosity of 63-73%. Place the plastic board on the on the drying trolley;

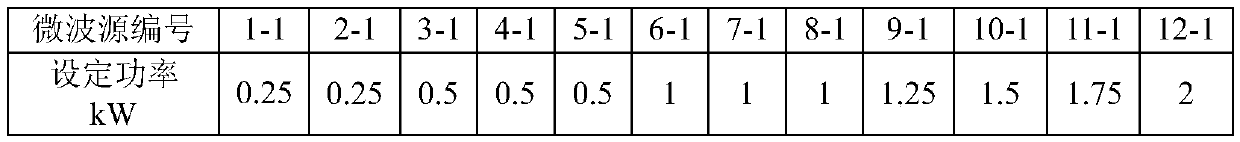

[0041] Step 2: After the drying trolley is full, push it into a microwave drying device in the form of a tunnel kiln. The microwave drying device is equipped with 12 microwave sources along the moving direction of the drying trolley. The specific microwave source setting parameters are shown in Table 1 below:

[0042] Table I

[0043]

[0044] The speed of the drying trolley is set to 0.5m / h;

[0045] Step 3: After the drying trolley drives out of the microwave drying device, remove the packaging carton of the dried catalyst body and put it on the calcining trolley, and push the calcining trolley into the microwave calcination device in the for...

Embodiment 2

[0050] A honeycomb type denitration catalyst rapid drying and calcination method, comprising the following steps:

[0051] Step 1: Pack the extruded 150×150×600mm, 22*22-hole wet catalyst embryo in a carton called sponge and put it on a plastic board with a porosity of 63-73%. Place the plastic board on a dry on the trolley;

[0052] Step 2: After the drying trolley is full, push it into the microwave drying device in the form of a tunnel kiln. The microwave drying device is equipped with 12 microwave sources along the moving direction of the drying trolley. The specific microwave source setting parameters are shown in Table 3 below:

[0053] Table three

[0054]

[0055] The speed of the drying trolley is set at 0.45m / h;

[0056] Step 3: After the drying trolley drives out of the microwave drying device, remove the catalyst packaging carton and put it on the calcining trolley, and push the trolley into the microwave calcination device in the form of a tunnel kiln. The trol...

Embodiment 3

[0061] A honeycomb type denitration catalyst rapid drying and calcination method, comprising the following steps:

[0062] Step 1: Pack the extruded 150×150×900mm, 30*30-hole catalyst wet embryo in a carton called sponge and put it on a plastic board with a porosity of 63-73%. Place the plastic board in a dry place on the trolley;

[0063] Step 2: After the drying trolley is full, push it into the microwave drying device in the form of a tunnel kiln. The microwave drying device is equipped with 12 microwave sources along the moving direction of the drying trolley. The specific microwave source setting parameters are shown in Table 5 below:

[0064] Table five

[0065]

[0066] The speed of the drying trolley is set to 0.4m / h;

[0067] Step 3: After the drying trolley drives out of the microwave drying device, remove the catalyst packaging carton and put it on the calcining trolley, and push the trolley into the microwave calcination device in the form of a tunnel kiln. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com