Composite bone charcoal powder as well as preparation method and application thereof

A technology of bone charcoal powder and bone charcoal, which is applied in chemical instruments and methods, other chemical processes, water/sludge/sewage treatment, etc., and can solve the problem that the specific surface area of bone charcoal powder has large differences, cannot meet market applications, and has large specific surface differences. etc., to achieve the effect of reducing the difficulty of calcination, avoiding large differences in specific surface area, and preventing the reduction of specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

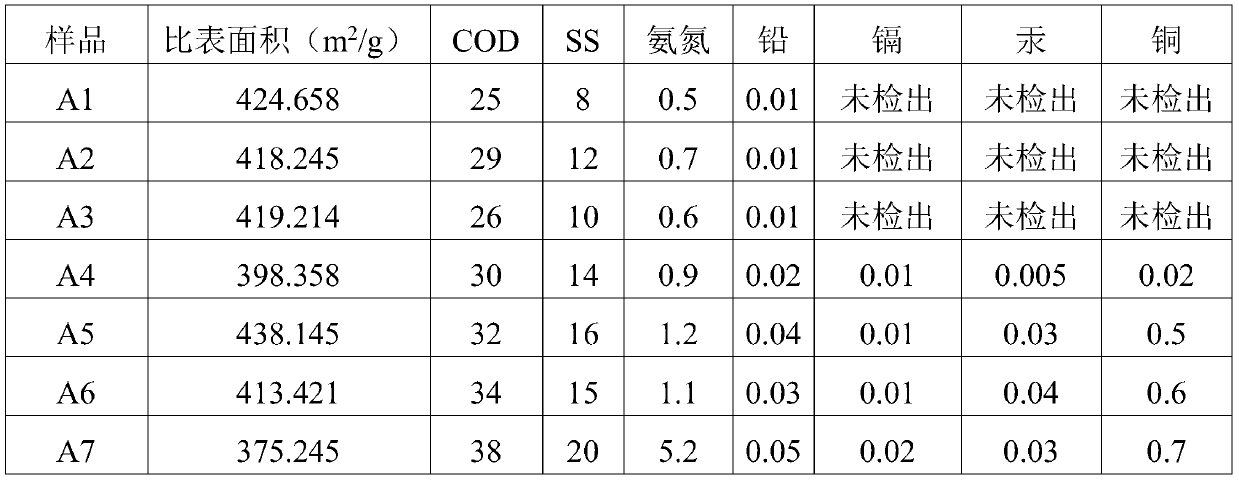

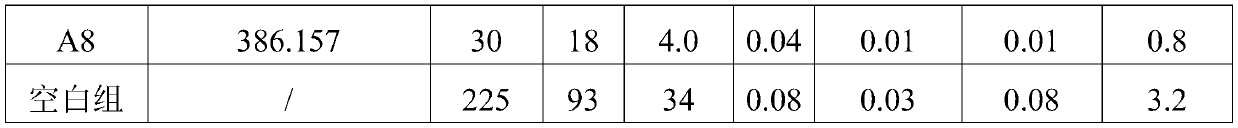

Examples

Embodiment 1

[0030] A preparation method of bone charcoal powder, comprising the following steps:

[0031] (1) Collect miscellaneous bones, remove debris, pulverize miscellaneous bones to obtain crushed aggregates with a particle size less than 1cm, then mix with biomass materials and fly ash to obtain mixed powder, and then send them into the bone charcoal furnace for initial burning;

[0032] The mixed powder contains 70% of crushed aggregate, 15% of straw powder, and 15% of commercially available first-grade fly ash, and the stated percentages are mass percentages;

[0033] The conditions for the initial calcination include: nitrogen protection, a calcination temperature of 550°C, and a calcination time of 40 minutes;

[0034] (2) Take out the mixed powder after initial burning, add the sodium hydroxide solution that molar concentration is 2mol / L to it, the weight ratio of described mixed powder and sodium hydroxide solution is 0.5:1; Filter, wash with water, and then dry the mixed pow...

Embodiment 2

[0040] Adjust the ratio of the mixed powder of step (1) in the embodiment 1, concrete: contain broken aggregate 55% in the mixed powder, straw powder 20%, commercially available primary fly ash 25%, described percentage The content is the mass percentage; the other preparation steps remain unchanged to obtain the bone charcoal powder, and the sample is recorded as A2.

Embodiment 3

[0042]Adjust the ratio of the mixed powder of step (1) in embodiment 1, concrete: contain broken aggregate 80% in the mixed powder, straw powder 5%, commercially available primary fly ash 15%, described percentage The content is the mass percentage; the other preparation steps remain unchanged to obtain the bone charcoal powder, and the sample is recorded as A3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com