A steel bag rotation furnace

A rotary furnace and ladle technology, applied in the direction of phosphorus compounds, inorganic chemistry, non-metallic elements, etc., can solve the problems of high working intensity, uneven heating of powder materials, large dust, etc., and achieve the effect of improving calcination efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

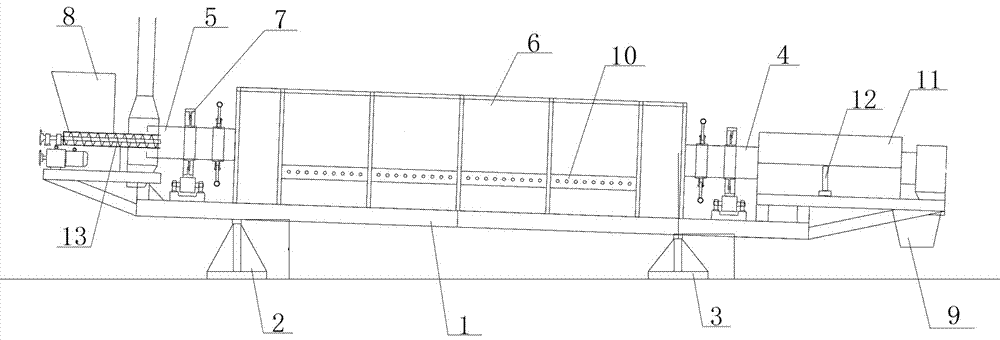

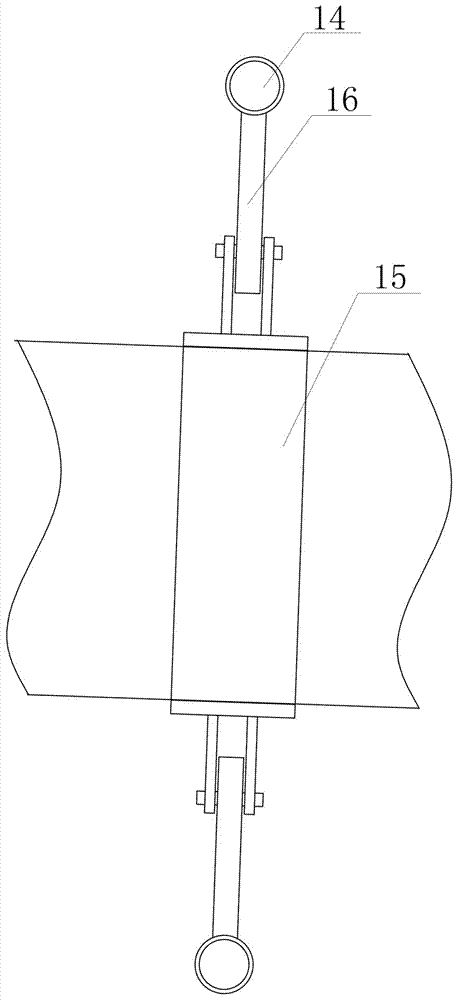

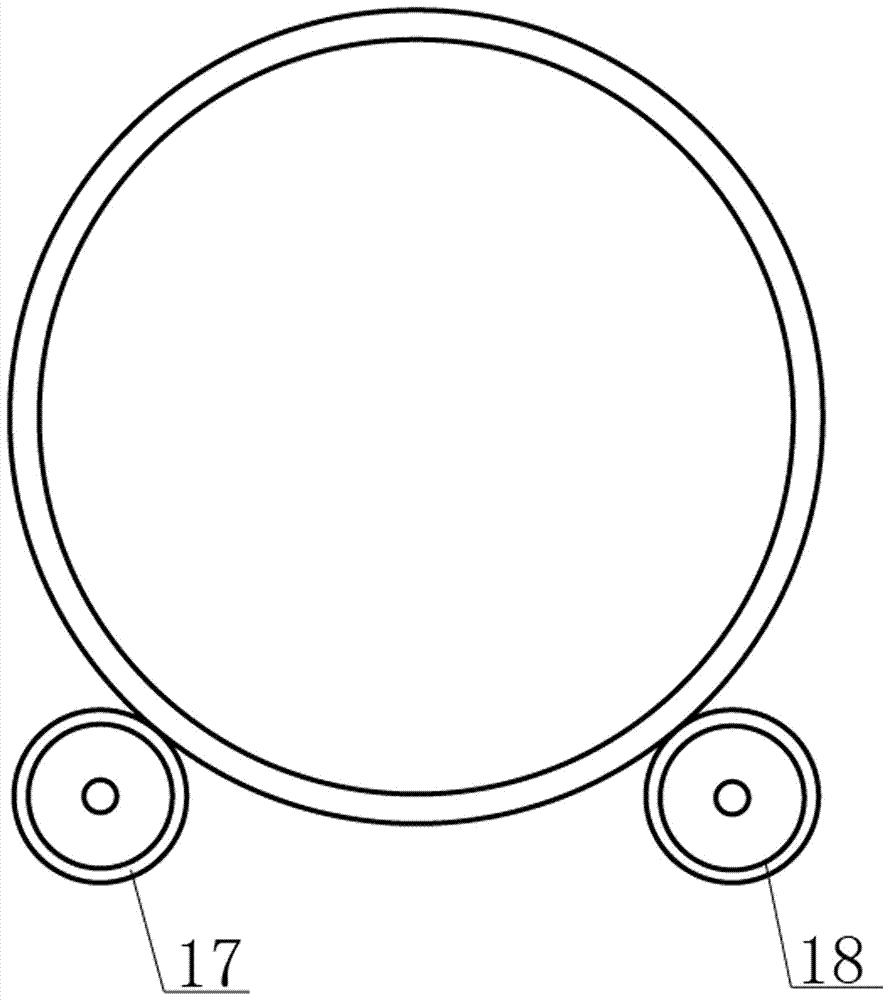

[0022] Such as figure 1 A ladle rotary furnace is shown, which includes a support body 1, the front section of the support body 1 and the bottom of the rear section are respectively provided with a spiral seat 2 and a twisted seat 3, and the support body 1 is provided with a furnace body, and the furnace body includes the front part of the feed The opening 5, the heating furnace 6 in the middle and the discharge port 4 at the rear are provided with a drive mechanism 7 at the bottom of the feed port 5 and the discharge port 4, and a drive mechanism 7 is provided at the top of the feed port 5. The storage bin 8 is provided with a cooling mechanism at the discharge port end 4 , a discharge mechanism 9 is provided at the end bottom of the discharge port end 4 , and a heating mechanism 10 is provided inside the heating furnace 6 .

[0023] The cooling mechanism includes a cooling water tank 11 and a cooling fan 12 , the cooling water tank 11 is arranged on the top of the discharge ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com