Multi-point limiting type engine ceramic blade calcining supporting frame

An engine and support frame technology, which is applied in the field of multi-point limit type engine ceramic blade calcination support frame, can solve the problems of low ceramic blade calcination efficiency, achieve good fixed support effect, stable connection, and large area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

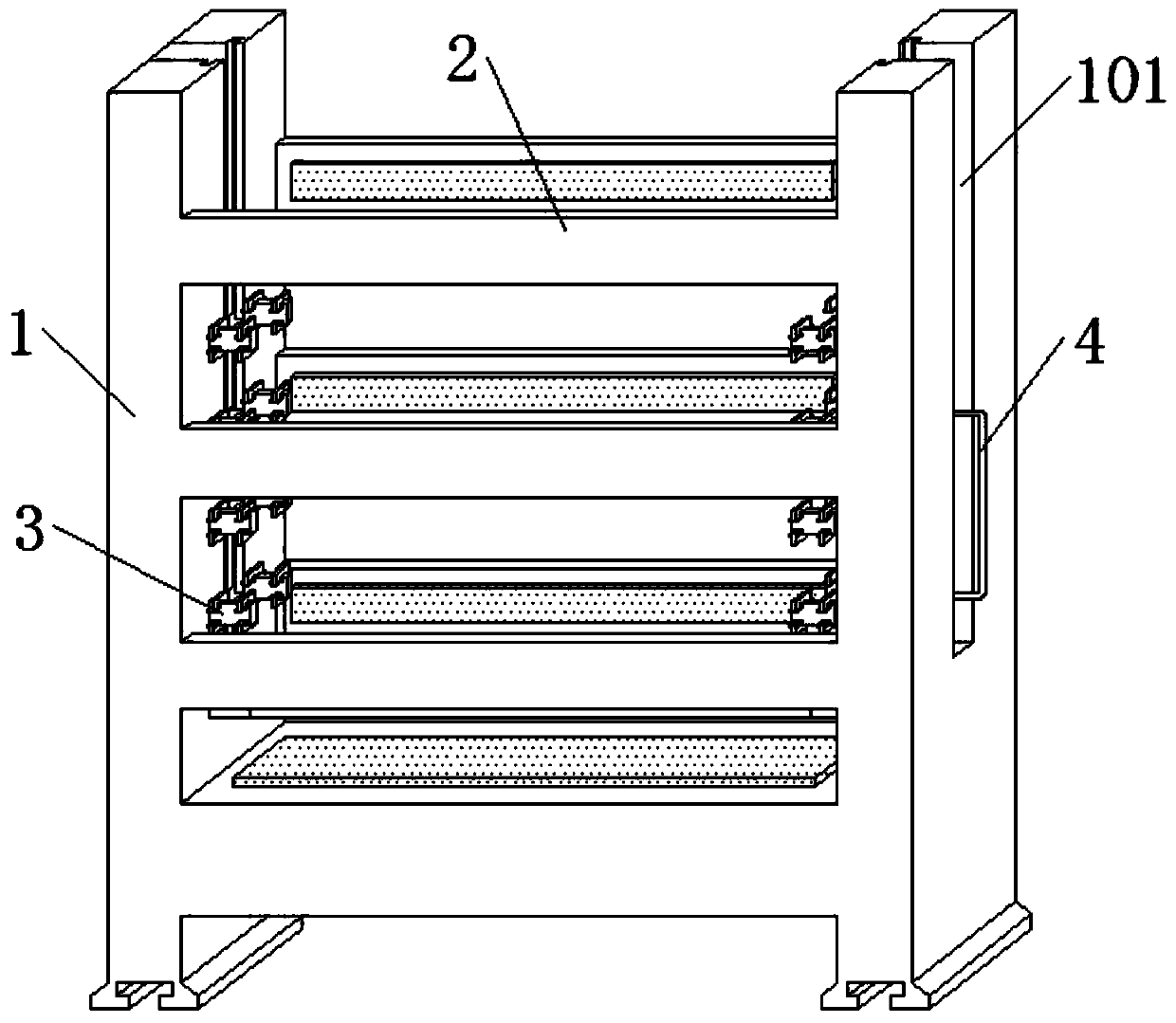

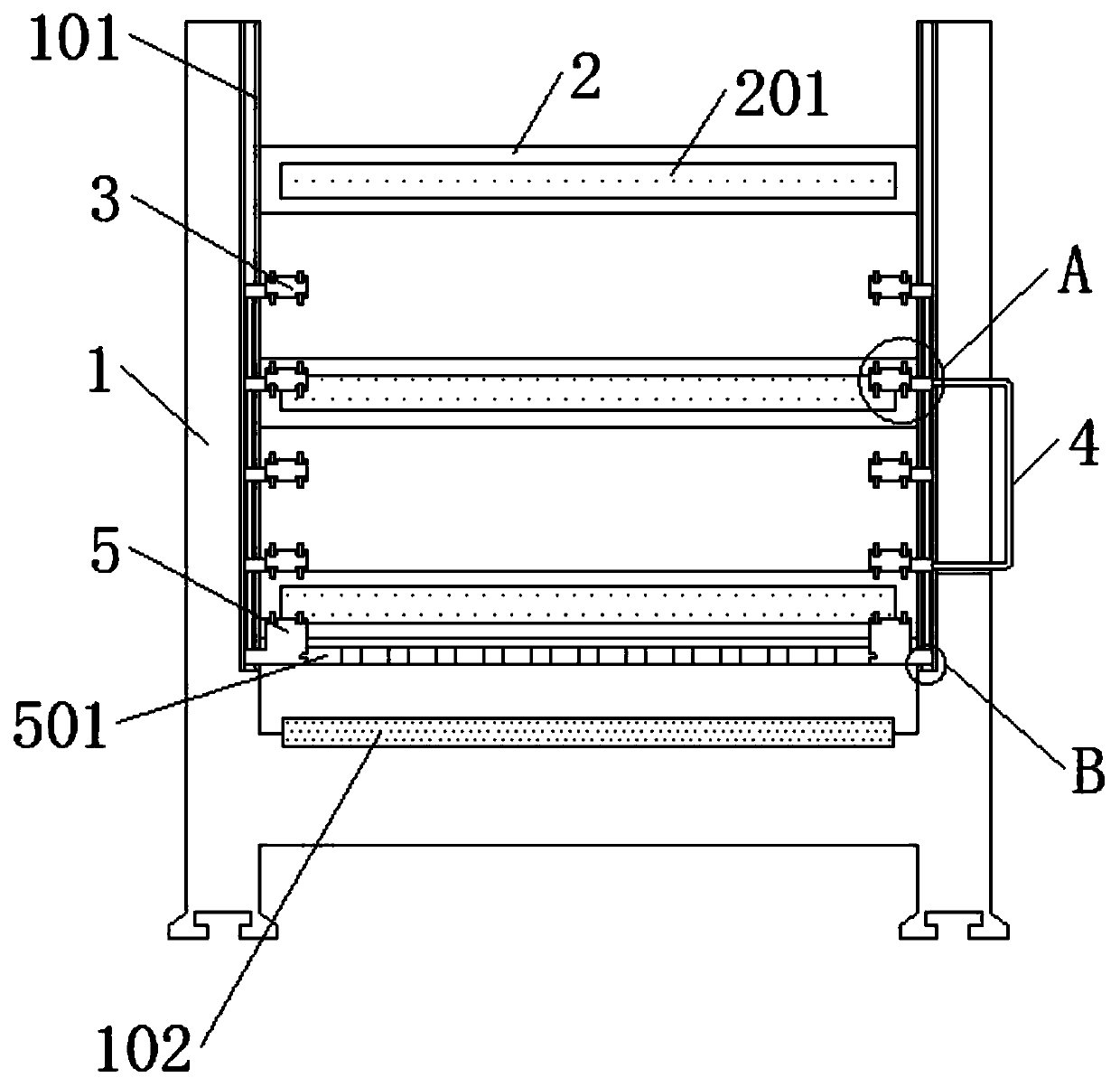

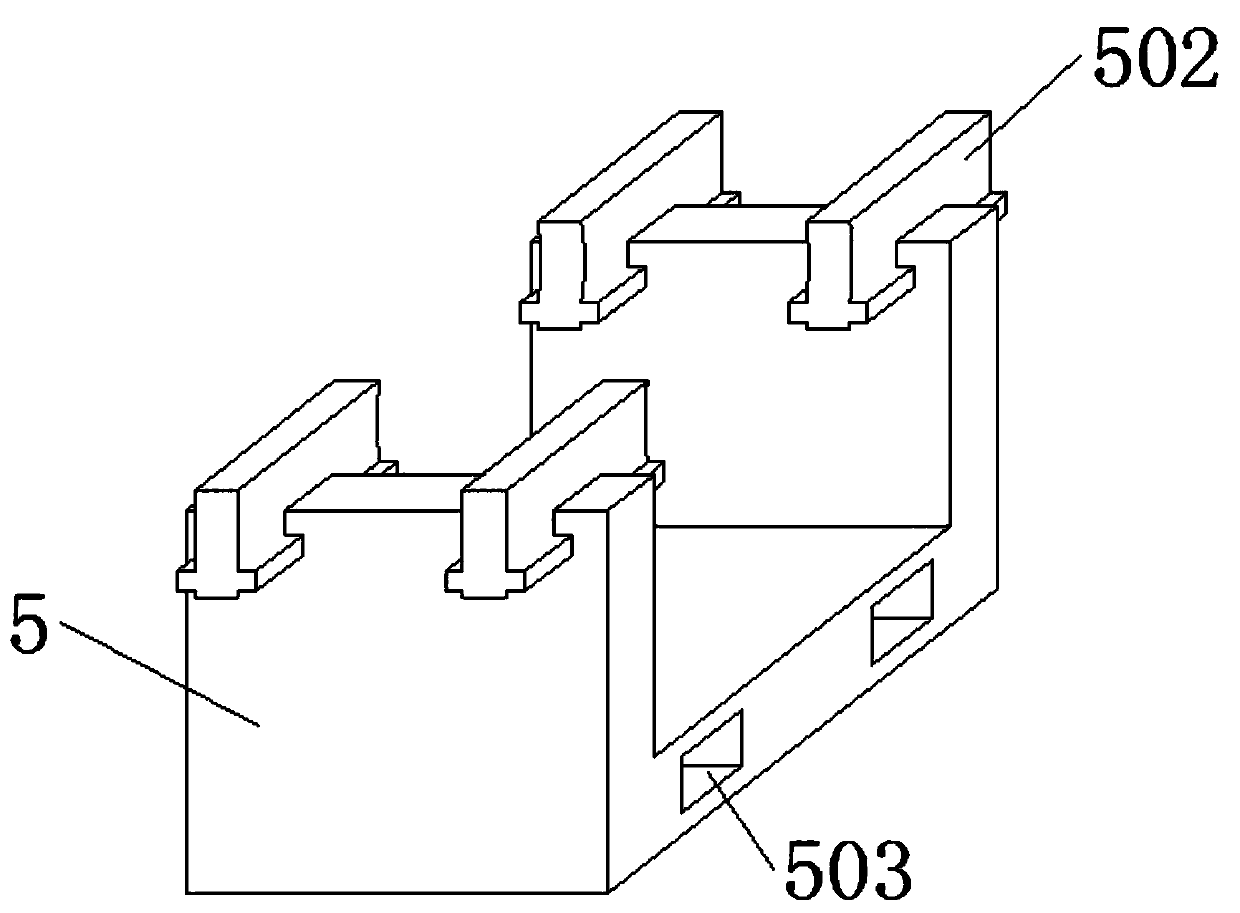

[0031] see figure 1 to attach Figure 9 , a multi-point limit type engine ceramic blade calcined support frame, including: a main frame 1, a chute 101, a horizontal plate 2, a limit block 3, a sliding rod 4 and a bottom support block 5, the front and rear ends of the main frame 1 Both ends are provided with horizontal plates 2, and the left and right ends of the main frame 1 are movably connected to the limit block 3 through the chute.

[0032] see Figure 1-2 , further, the main frame 1 is set in a "concave" shape, and the left and right sides of the bottom of the main frame 1 are provided with "T"-shaped grooves, and the "T"-shaped grooves fit with the external "T" slide rails, and The top of the middle part of the main frame 1 is embedded with a heat-conducting bottom plate 102, the bottom of the chute 101 is fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com