New gate valve and gate valve assembly method

A gate valve, a new type of technology, applied in valve devices, valve details, sliding valves, etc., can solve the problems of easy loosening of bolts and nuts, strengthen the limiting function of the positioning ring, etc., to achieve strong limiting ability, and enhance reliability. shedding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

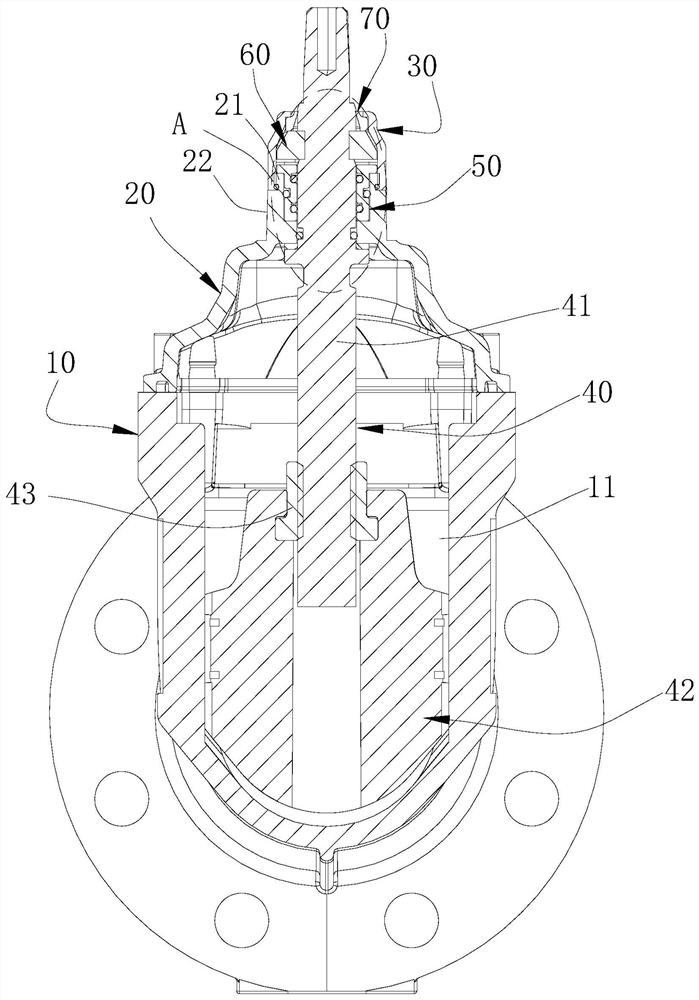

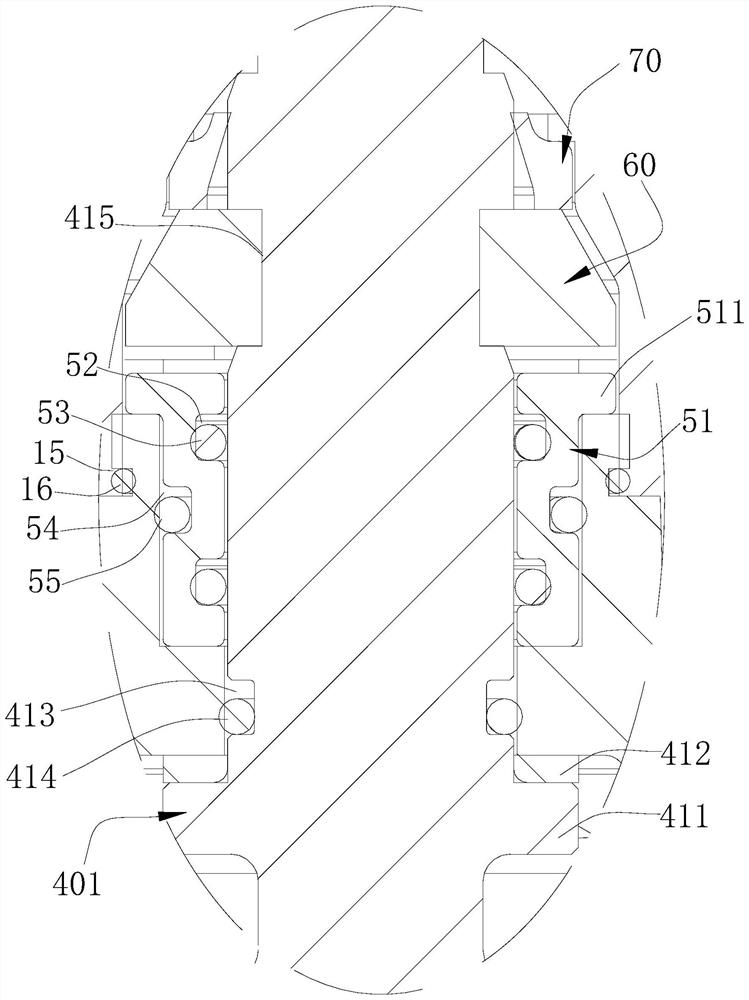

[0062] See figure 1 and figure 2 , the new gate valve 100 also includes a sealing letter 50 , the sealing letter 50 is arranged inside the valve cover 20 and sleeved outside the valve stem 41 for sealing connection between the valve stem 41 and the valve cover 20 . The sealing letter 50 is made of rigid materials such as stainless steel.

[0063] The sealing letter 50 is provided with a first matching portion 51 , and the valve cover 20 is provided with a first limiting portion 23 , the cooperation between the first matching portion 51 and the first limiting portion 23 can position and install the sealing letter 50 on the valve cover 20 Inside.

[0064] In this embodiment, the first fitting part 51 is a boss 511, and the boss 511 is arranged on the end of the sealing letter 50 away from the valve flap 42, and the first limiting part 23 is a limiting groove 231, and the limiting groove 231 is opened on the second On the end surface of the first section 21 away from the seco...

Embodiment 2

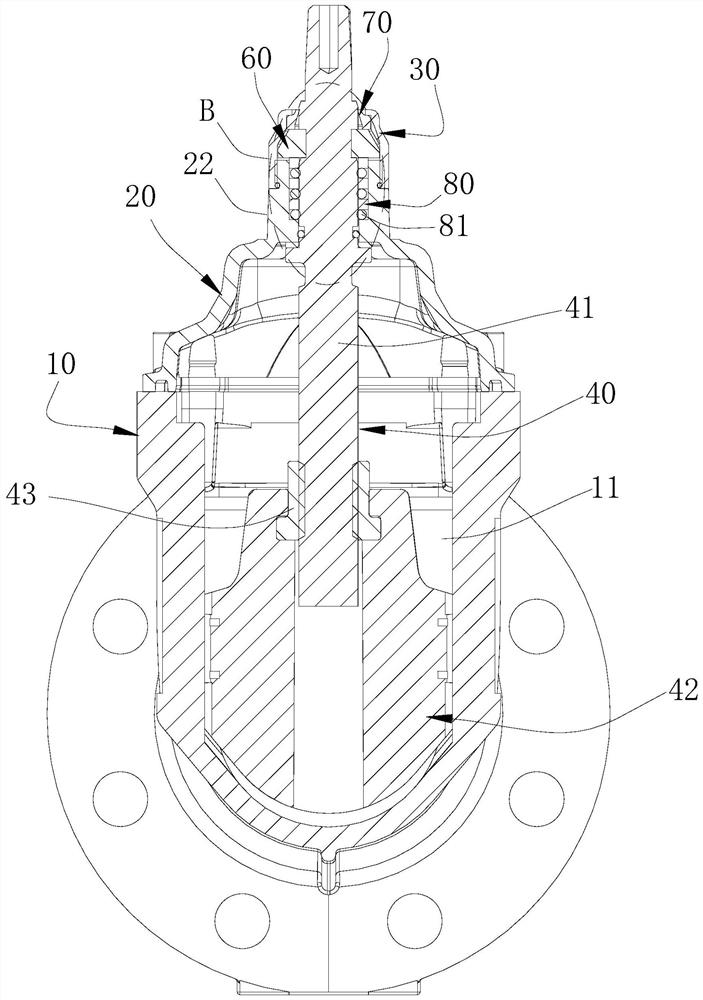

[0082] See image 3 and Figure 4 , the structure of this embodiment is basically the same as that of Embodiment 1, and the similarities will not be repeated, and the difference is:

[0083] The envelope 80 is used to replace the sealing letter 50. There are multiple envelopes 80, and the plurality of envelopes 80 are arranged outside the valve stem 41 at intervals. The fifth sealing member 81 is arranged between adjacent envelopes 80, and the envelope 80 is close to the position of the positioning ring 60. The end surface of one end abuts against the positioning ring 60 . The envelope 80 is made of flexible materials such as plastics and rubber.

[0084] When the valve stem 41 is rotated counterclockwise, since the sleeve 80 is separated from the sleeve 80 by the fifth sealing member 81, and there is an extrusion space in the middle, the valve stem 41 moves toward the direction of the valve disc 42, and the positioning ring 60 can be squeezed. The envelope 80 releases the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com