Method for reductively decomposion of ardealite by composite reducer

A reducing agent and phosphogypsum technology, applied in chemical instruments and methods, sulfur compounds, inorganic chemistry, etc., can solve environmental problems and achieve the effects of reducing reaction temperature, production cost, and energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

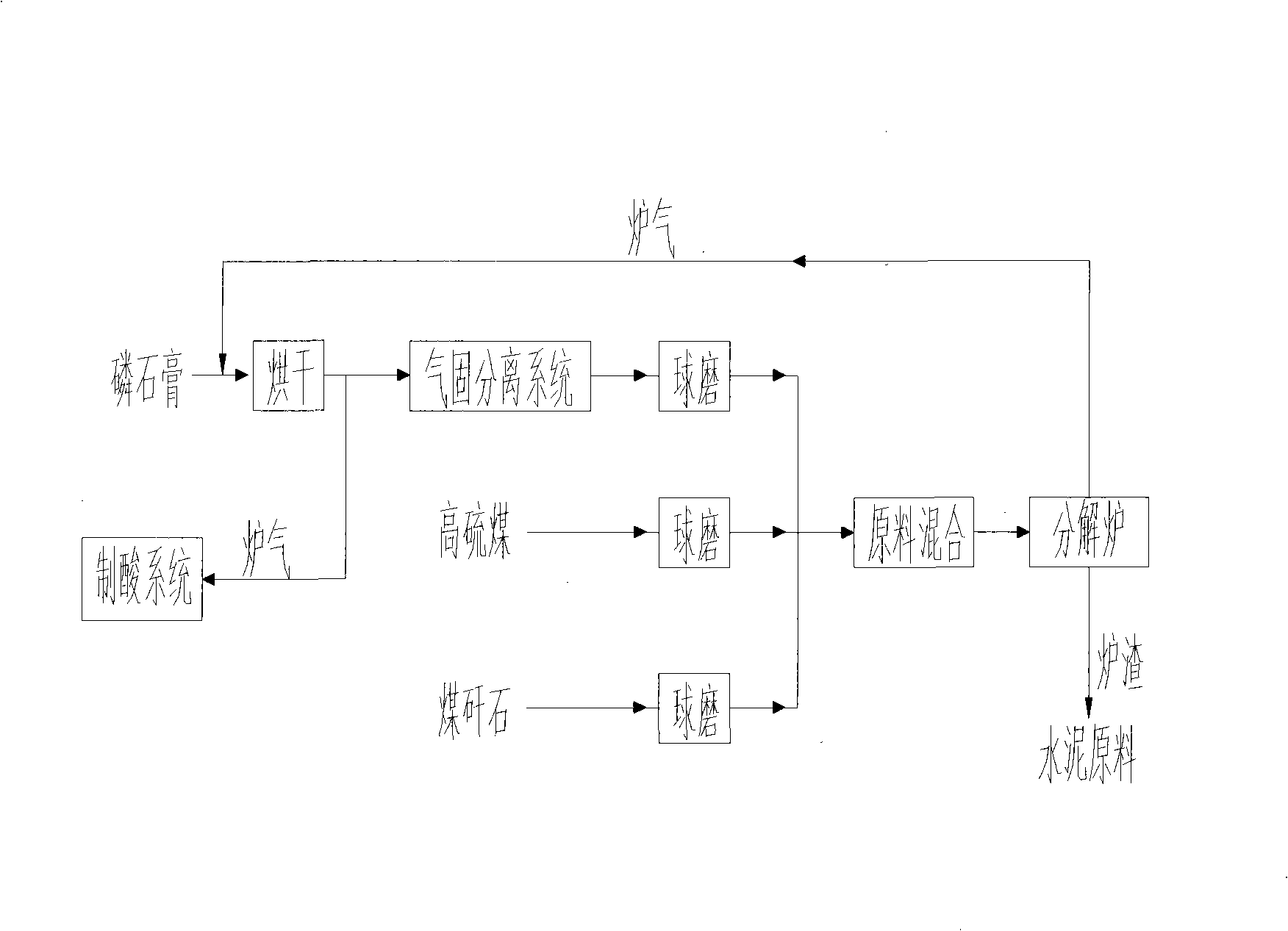

Image

Examples

Embodiment 1

[0028] Embodiment 1: first heat reduction decomposition furnace, control temperature at 800 ℃, get the phosphogypsum powder after drying and grinding (main component: CaSO 4 .2H 2 O mass fraction is 76.69%, SiO 2 Mass fraction is 17.06%) 1000g, 100 mesh high-sulfur coal (C mass fraction is 88.72%, S mass fraction is 3.56%) 36g, 100 mesh gangue (C mass fraction is 10.02%, S mass fraction is 2.54%) 36g , after mixing evenly, send it into the decomposition furnace, and detect SO in the flue gas after the reaction starts 2 The average volume percentage content is 8.78%. After the reaction is complete, stop heating, and after natural cooling, take out the solid product for analysis and calculation. It can be calculated that the decomposition rate of phosphogypsum is 66.29%, the desulfurization rate is 59.37%, and the calcium oxide content is 55.6%. , cannot be used as a raw material for cement production.

Embodiment 2

[0029] Embodiment 2: first heat reduction decomposition furnace, control temperature at 1000 ℃, take dry and ground phosphogypsum powder 1000g, 100 mesh high-sulfur coal 36g, 100 mesh coal gangue 36g, after uniform mixing, send in the decomposition furnace, Detection of SO in the flue gas after the reaction starts 2 The average volume percentage content is 14.98%, the reaction is complete, stop heating, after natural cooling, take out the solid product for analysis and calculation, it can be calculated that the decomposition rate of phosphogypsum is 78.24%, the desulfurization rate is 83.70%, and the calcium oxide content is 69.95%. , can be directly used as raw material for cement production.

Embodiment 3

[0030] Embodiment 3: first heat reduction decomposition furnace, control temperature at 1000 DEG C, take dry and ground phosphogypsum powder 1000g, 100 mesh high-sulfur coal 18g, 100 mesh coal gangue 180g, after uniform mixing, send in the decomposition furnace, Detection of SO in the flue gas after the reaction starts 2 The average volume percentage content is 6.95%. After the reaction is complete, stop heating, and after natural cooling, take out the solid product for analysis and calculation. It can be calculated that the decomposition rate of phosphogypsum is 65.44%, the desulfurization rate is 60.82%, and the calcium oxide content is 60.38%. , cannot be directly used as raw material for cement production.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com