Regeneration method for inactivated TiV-based honeycomb denitration catalyst having combined denitration and demercuration modification function

A denitration catalyst, vanadium-titanium-based technology, applied in the field of regeneration of deactivated vanadium-titanium-based honeycomb denitration catalyst combined with denitrification and demercury modification, to achieve high catalytic activity, improve mercury oxidation ability, and improve denitrification activity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

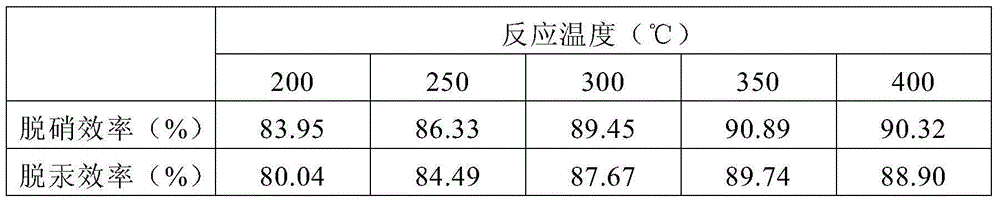

Embodiment 1

[0025] In this experiment, a vanadium-titanium-based honeycomb denitrification catalyst deactivated in a power plant was used as the experimental raw material. The cross-sectional size of the catalyst was 150mm×150mm. Small pieces of 30mm×30mm×50mm were cut from the raw material for regeneration. The steps are as follows:

[0026] Step 1: Analyze the cause of catalyst deactivation, the results are as follows:

[0027] (1) After the catalyst has been used for a certain period of time, its denitrification efficiency has dropped significantly, and the decline rate has reached more than 40%, which is determined to be deactivated;

[0028] (2) The surface of the deactivated catalyst is obviously clogged, but the specific surface area and pore volume do not decrease significantly;

[0029] (3) The crystal form of the catalyst changes partially, TiO 2 It still exists in the anatase type with good catalytic activity, but the molding material SiO 2 The crystal structure changes, whic...

Embodiment 2

[0051] Step 1: Cut a 30 mm × 30 mm × 50 mm small piece of deactivated catalyst from the deactivated catalyst raw material of the same power plant in Example 1 for regeneration, put the catalyst into deionized water and ultrasonically clean it for 40 minutes, and remove the dust in the catalyst honeycomb channel .

[0052] Step 2: Put the catalyst after water washing into 0.2% H 2 SO 4 The solution was ultrasonically cleaned for 40 minutes, and the acid-washed catalyst was rinsed with water until pH = 4-6, and stood until no water flowed down.

[0053] Step 3: Immerse the acid-washed catalyst in the combined denitrification and demercuration regeneration solution, the concentration of oxalic acid in the regeneration solution is 0.5wt%, the concentration of ammonium metavanadate is 0.7wt%, the concentration of ammonium metatungstate is 3.5wt%, nitric acid The concentration of cerium is 1wt%, the concentration of copper chloride is 0.1wt%, the immersion time is 30min, and after...

Embodiment 3

[0060] Step 1: Cut a 30 mm × 30 mm × 50 mm small piece of deactivated catalyst from the deactivated catalyst raw material of the same power plant in Example 1 for regeneration, put the catalyst into deionized water and ultrasonically clean it for 40 minutes, and remove the dust in the catalyst honeycomb channel .

[0061] Step 2: Put the catalyst cleaned by water into a NaOH solution with a mass concentration of 0.5% for ultrasonic cleaning for 30 minutes, and then put it into a 0.2% H 2 SO 4 The solution was ultrasonically cleaned for 40 minutes, and the acid-washed catalyst was rinsed with water until pH = 4-6, and stood until no water flowed down.

[0062] Step 3: Immerse the acid-washed catalyst in the combined denitrification and demercuration regeneration solution, the concentration of oxalic acid in the regeneration solution is 0.5wt%, the concentration of ammonium metavanadate is 1wt%, the concentration of ammonium metatungstate is 5wt%, and the concentration of ceriu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com