Method for desorbing residual carbon in siliceous dust by means of oxygen-enriched calcination and device therefor

A technology of removing and silica fume, applied in chemical instruments and methods, silicon oxide, silicon dioxide, etc., can solve the problem that the removal efficiency of residual carbon is not obvious, shorten the calcination time, ensure the constant diameter, improve the The effect of oxidation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

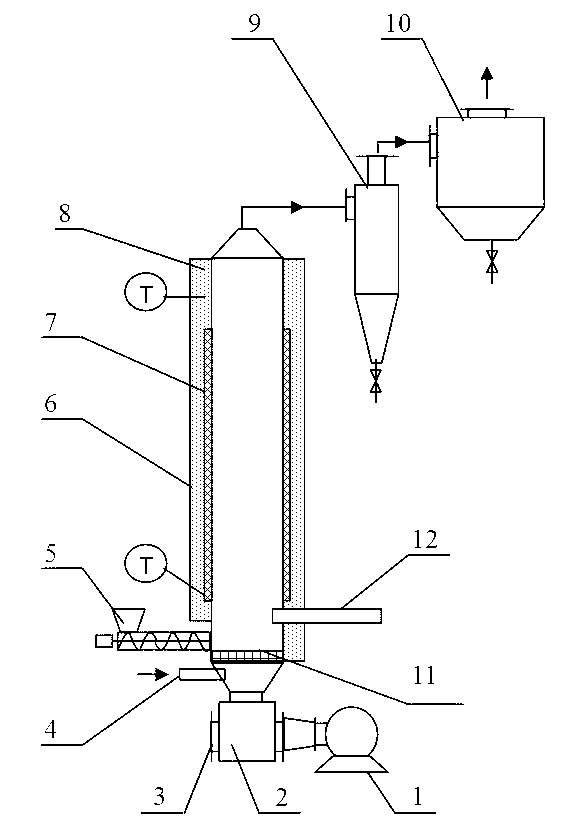

[0036] The shell of the fluidized bed calcination tower 8 is welded by refractory steel, and refractory bricks are built in the steel shell; the diameter of the effective space in the fluidized bed calcination tower 8 is 1400 mm, and the effective height is 12000 mm. A gas delivery pipe 12 is provided at the bottom of the fluidized bed calcination tower 8. The gas delivery pipe 12 transports natural gas (or coal gas) into the tower, and the natural gas is burned to provide heat to ensure that the temperature inside the tower is 720°C during the calcination process. The outer periphery of the fluidized bed calcination tower 8 is wrapped with an insulating layer 6, the thickness of the insulating layer 6 is 260 mm, so as to effectively prevent heat loss in the tower. Thermocouples are respectively installed at the upper and lower parts of the fluidized bed calciner 8 for measuring and controlling the temperature inside the fluidized bed calciner 8 to keep at 720°C.

[0037] A ba...

Embodiment 2

[0042] The fluidized bed calcination tower 8 is made of a corundum tube with an inner diameter of 100mm and a length of 1200mm. An electric heater 7 with a total power of 4Kw is installed around the outside of the fluidized bed calcination tower 8 to ensure that the temperature inside the tower is 760°C during the calcination process. . The insulation layer 6 is wrapped around the electric heater 7 and the fluidized bed calcining tower 8, and the thickness of the insulation layer 6 is 300mm, so as to effectively prevent heat loss in the tower. Thermocouples are respectively installed on the upper and lower parts of the fluidized bed calciner 8 to measure and control the temperature of the fluidized bed calciner 8 to keep at 760°C.

[0043] The bottom of the fluidized bed calciner 8 is provided with a cube-shaped housing base 2 with a side length of 400 mm. The upper part of the base 2 is provided with a round hole with a diameter of 120 mm, that is, an air outlet, which commun...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com