Method for preparing large-granularity cobaltosic oxide

A technology of tricobalt tetroxide and large particle size, applied in the direction of cobalt oxide/cobalt hydroxide, etc., can solve problems such as unfavorable industrial production, cumbersome process, etc., and achieve the effects of improving washing performance, improving direct yield and saving production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

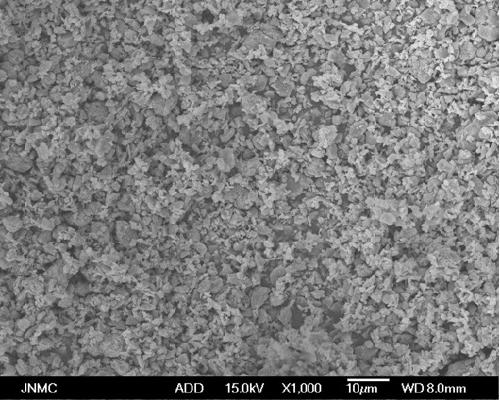

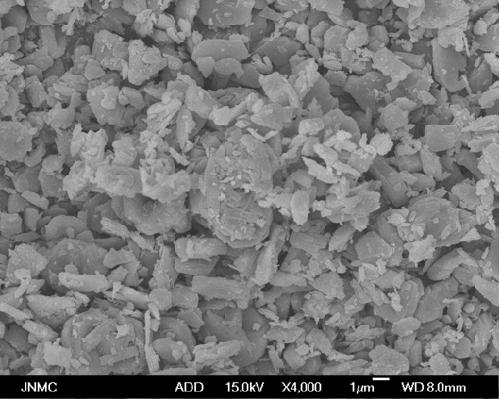

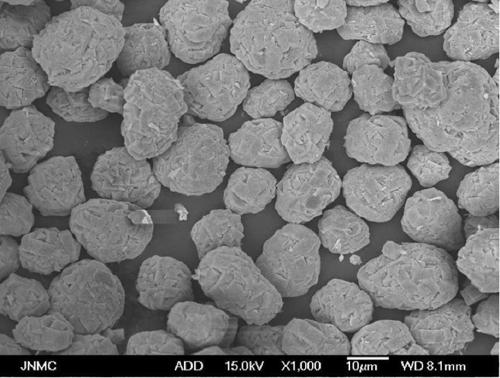

Image

Examples

Embodiment 1

[0039] The production steps are the same as above, and will not be repeated here. The specific parameters in each step are as follows:

[0040] The configured A solution is 1mol / L cobalt chloride solution, the prepared B solution is 2mol / L sodium hydroxide solution, the configured C solution is 5mol / L ammonia solution, and the concentration of 5ml is added in every liter of ammonia solution. 80% hydrazine hydrate solution.

[0041] Prepare seed crystals. Before the start of the synthesis reaction, add 100kg of cobalt hydroxide flash-dried dust collector and 10L of hydrazine hydrate into the reaction kettle, stir for 2 hours at a stirring intensity of 200 rpm, and start the synthesis reaction.

[0042] synthesis reaction. At the beginning of the synthesis reaction, A solution, B solution, and C solution were added into the reaction kettle in parallel, and the synthesis reaction was carried out under strong stirring. During the reaction, the flow rate of A solution was strict...

Embodiment 2

[0050] The production steps are the same as above, and will not be repeated here. The specific parameters in each step are as follows:

[0051] The configured A solution is 1.5mol / L cobalt sulfate solution, the prepared B solution is 4mol / L sodium hydroxide solution, the configured C solution is 8mol / L ammonia solution, and the concentration of 12ml is added in every liter of ammonia solution. 80% hydrazine hydrate solution.

[0052] Prepare seed crystals. Before the start of the synthesis reaction, add 150kg of cobalt hydroxide flash-dried dust collector and 15L of hydrazine hydrate into the reaction kettle, stir for 3 hours at a stirring intensity of 180 rpm, and start the synthesis reaction.

[0053] synthesis reaction. At the beginning of the synthesis reaction, A solution, B solution, and C solution were added into the reaction kettle in parallel, and the synthesis reaction was carried out under strong stirring. During the reaction, the flow rate of A solution was stri...

Embodiment 3

[0061] The production steps are the same as above, and will not be repeated here. The specific parameters in each step are as follows:

[0062] The configured A solution is a 2mol / L cobalt nitrate solution, the prepared B solution is a 6mol / L sodium hydroxide solution, and the configured C solution is a 10mol / L ammonia solution, and the concentration of 80 ml is added to each liter of ammonia solution. % hydrazine hydrate solution.

[0063] Prepare seed crystals. Before the start of the synthesis reaction, add 200kg of cobalt hydroxide flash-dried dust collector and 20L of hydrazine hydrate into the reactor, stir for 4 hours at a stirring intensity of 150 rpm, and start the synthesis reaction.

[0064] synthesis reaction. At the beginning of the synthesis reaction, A solution, B solution, and C solution were added into the reaction kettle in parallel, and the synthesis reaction was carried out under strong stirring. During the reaction, the flow rate of A solution was stric...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| laser granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com