Preparation method of lithium ion battery cathode material carbon-coated columnar lithium vanadium phosphate

A lithium-ion battery, cathode material technology, applied in battery electrodes, chemical instruments and methods, circuits, etc., can solve the problems of difficult mass production, long production cycle, easy powder agglomeration, etc., to achieve uniform size and short calcination time , the effect of low calcination temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Step 1: By heating and stirring, the NH 4 VO 3 Dissolve in deionized water, the solution concentration is 0.06mol / L, add LiOH·H 2 O, citric acid and H 3 PO 4 , stir, and form a transparent yellow precursor solution after mixing evenly, in which LiOH·H 2 O, NH 4 VO 3 、H 3 PO 4 The molar ratio with citric acid is 3:2:3:2.

[0017] Step 2: Put the precursor solution in a hydrothermal kettle and react at 160°C for 1~2 hours. After the reaction is completed and the temperature drops to room temperature, open the reaction kettle and take out the blue gel-like product in the kettle.

[0018] Step 3: Put the blue gel-like product in an oven, dry at 90-100°C for 12-15 hours to obtain a xerogel, and then grind the xerogel into a powder with an agate mortar.

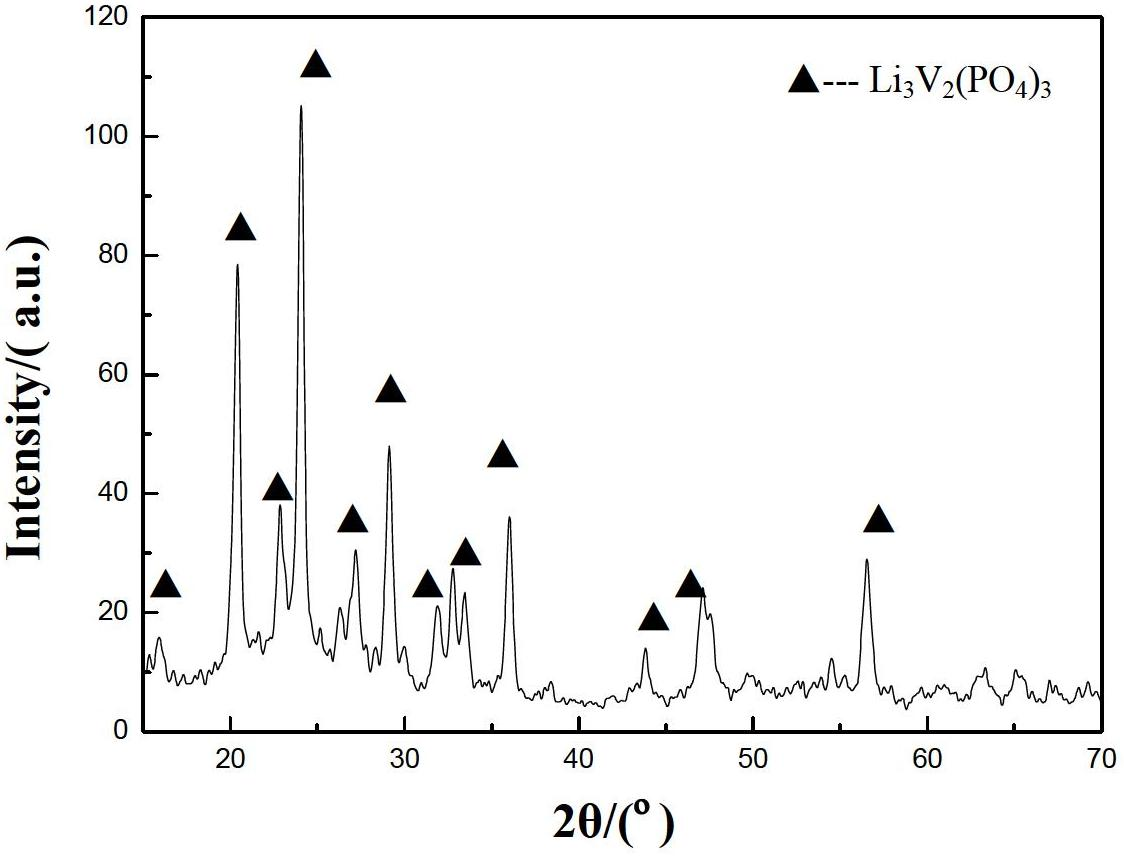

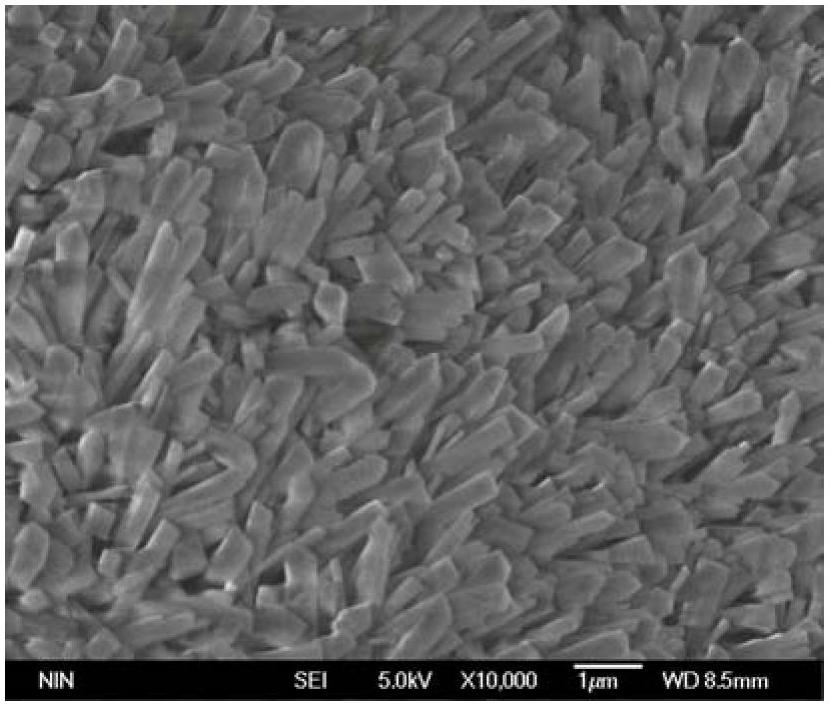

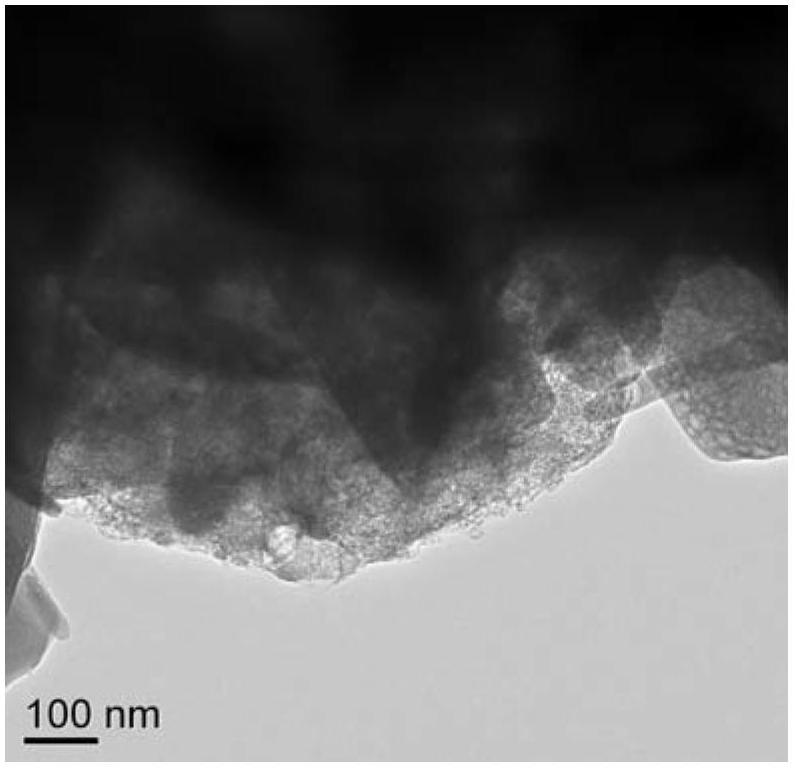

[0019] Step 4: Put dry gel powder in N 2 Calcined under protective conditions for 6 hours, the calcination temperature was 700 ° C, and after cooling down, carbon-coated columnar Li 3 V 2 (PO 4 ) 3 Powder.

Embodiment 2

[0021] Step 1: By heating and stirring, the NH 4 VO 3 Dissolve in deionized water, the solution concentration is 0.08mol / L, add LiOH·H 2 O, citric acid and H 3 PO 4 , stir, and form a transparent yellow precursor solution after mixing evenly, in which LiOH·H 2 O, NH 4 VO 3 、H 3 PO 4 The molar ratio with citric acid is 3:2:3:2.

[0022] Step 2: Put the precursor solution in a hydrothermal kettle and react at 160°C for 1~2 hours. After the reaction is completed and the temperature drops to room temperature, open the reaction kettle and take out the blue gel-like product in the kettle.

[0023] Step 3: Put the blue gel-like product in an oven, dry at 90-100°C for 12-15 hours to obtain a xerogel, and then grind the xerogel into a powder with an agate mortar.

[0024] Step 4: Put dry gel powder in N 2 Calcined under protective conditions for 6 hours, the calcination temperature was 700 ° C, and after cooling down, carbon-coated columnar Li 3 V 2 (PO 4 ) 3 Powder.

Embodiment 3

[0026] Step 1: By heating and stirring, the NH 4 VO 3 Dissolve in deionized water, the solution concentration is 0.10mol / L, add LiOH·H 2 O, citric acid and H 3 PO 4 , stir, and form a transparent yellow precursor solution after mixing evenly, in which LiOH·H 2O, NH 4 VO 3 、H 3 PO 4 The molar ratio with citric acid is 3:2:3:2.

[0027] Step 2: Put the precursor solution in a hydrothermal kettle and react at 160°C for 1~2 hours. After the reaction is completed and the temperature drops to room temperature, open the reaction kettle and take out the blue gel-like product in the kettle.

[0028] Step 3: Put the blue gel-like product in an oven, dry at 90-100°C for 12-15 hours to obtain a xerogel, and then grind the xerogel into a powder with an agate mortar.

[0029] Step 4: Put dry gel powder in N 2 Calcined under protective conditions for 6 hours, the calcination temperature was 700 ° C, and after cooling down, carbon-coated columnar Li 3 V 2 (PO 4 ) 3 Powder.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com