Imaging device and imaging method

An image and medium technology, applied in printing devices, copying/marking methods, printing, etc., can solve the problems of inability to print high-quality images, increased gap between inkjet head and transfer pad, inaccurate ink drop landing, etc. problem, achieve the effect of shortening image forming time, suppressing color shift, and reducing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach ]

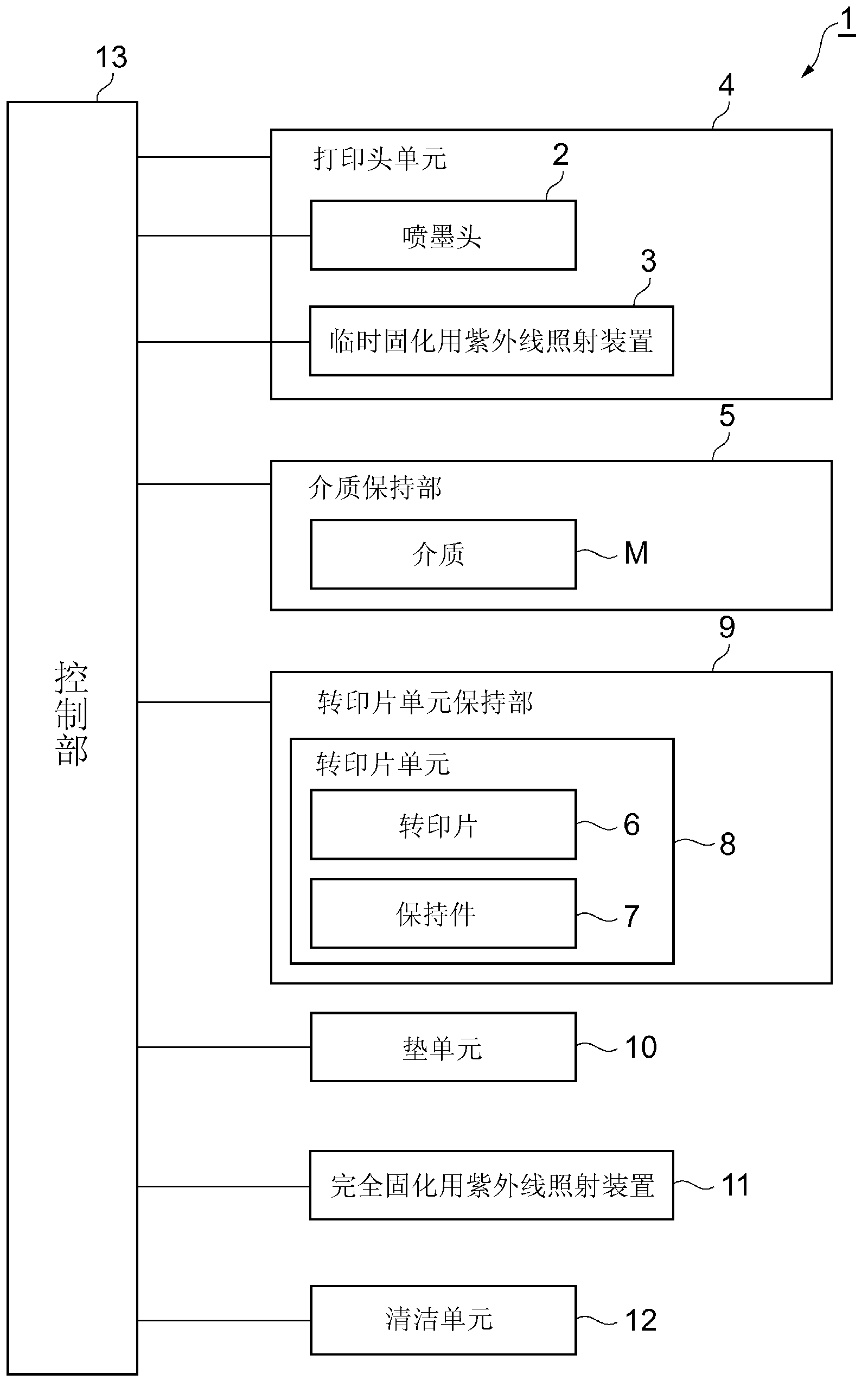

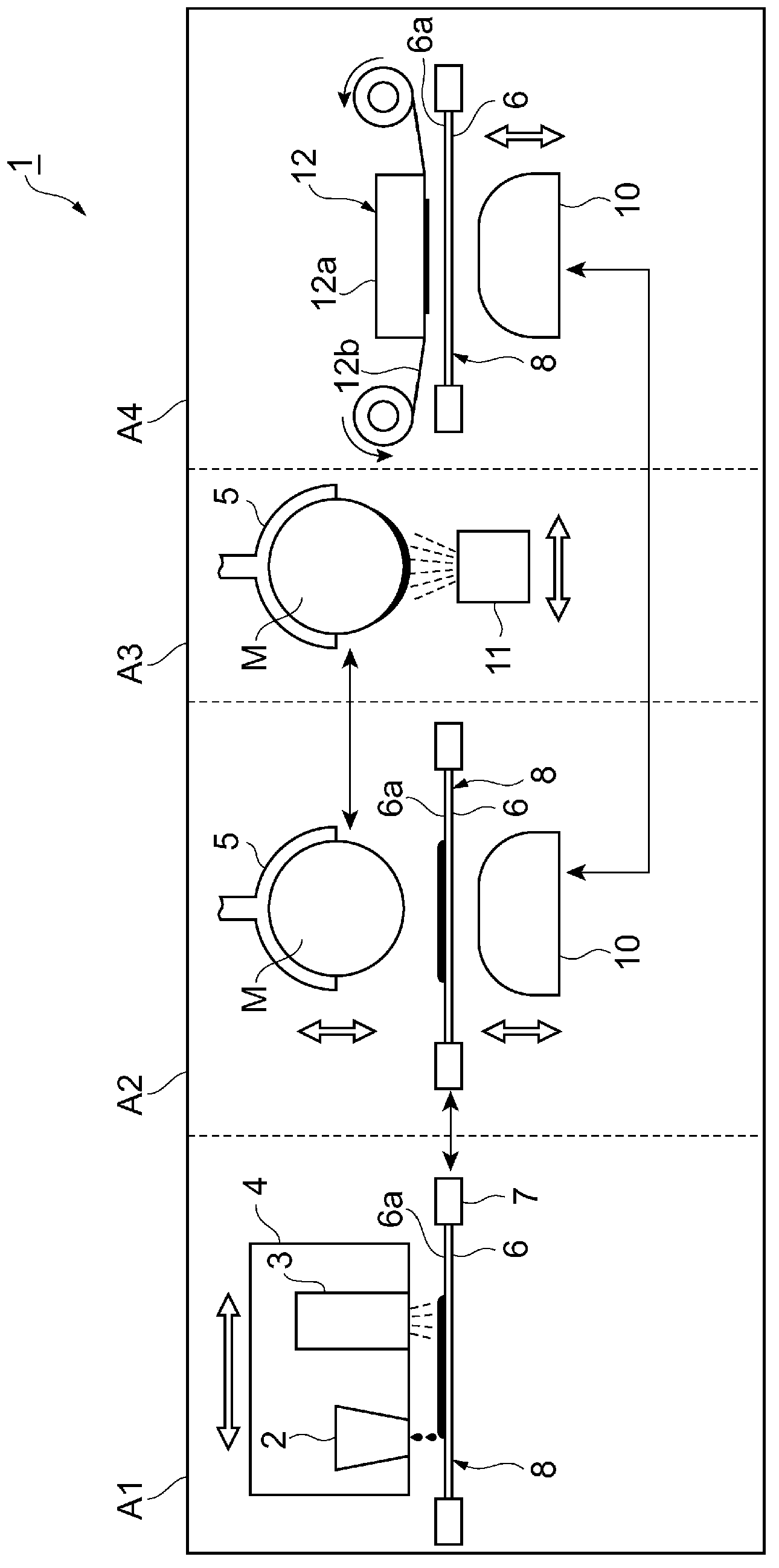

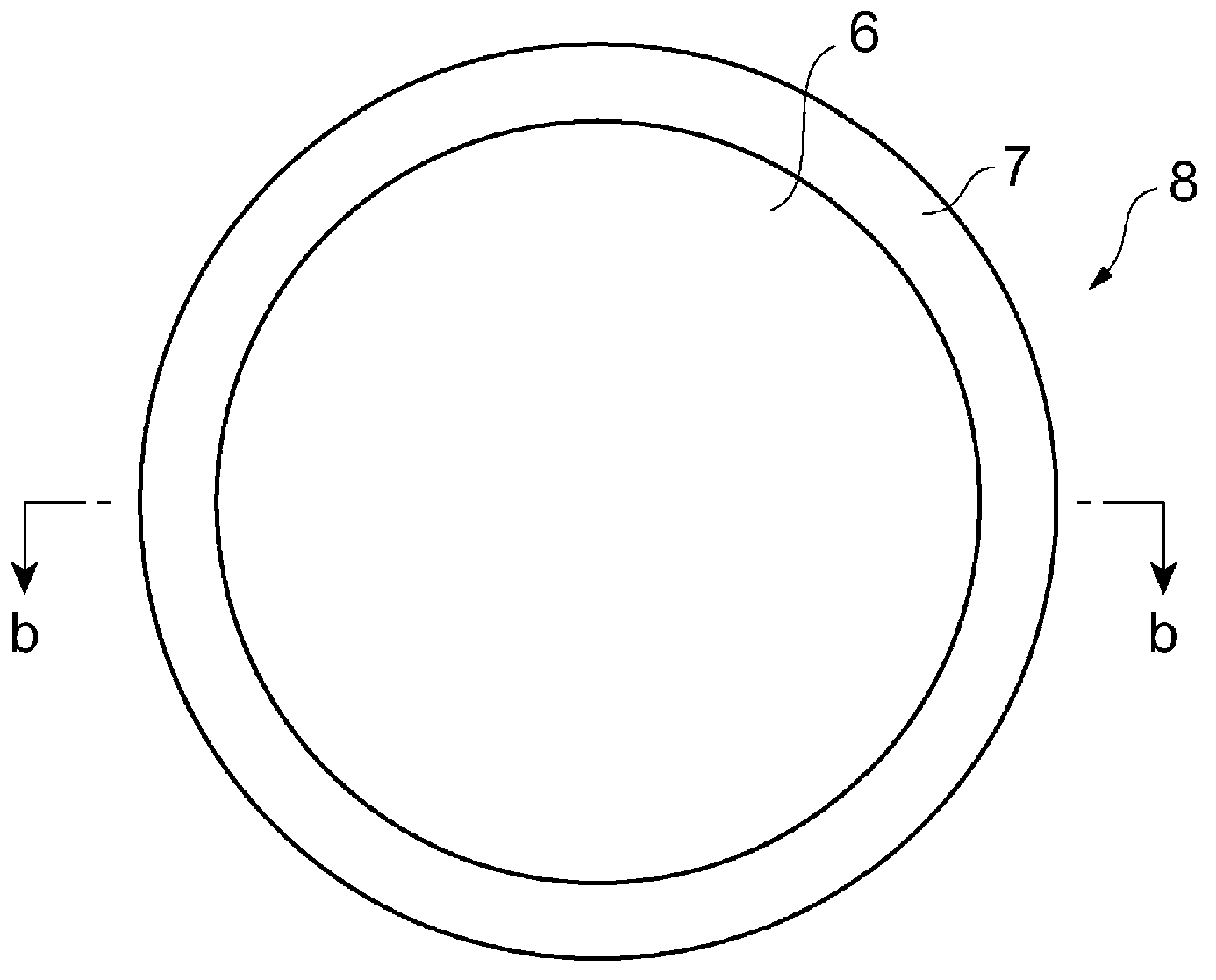

[0060] figure 1 It is a figure which shows the schematic structure of the inkjet printer of 1st Embodiment. figure 2 Yes figure 1 The schematic configuration diagram of the inkjet printer shown. Such as figure 1 with figure 2 As shown, the inkjet printer 1 includes: an inkjet head 2, an ultraviolet irradiation device 3 for temporary curing, a print head unit 4 for mounting the inkjet head 2 and an ultraviolet irradiation device 3 for temporary curing, and a medium for holding a medium M Holding part 5, transfer sheet unit holding part 9 for holding the transfer sheet unit 8 with the transfer sheet 6 mounted on the transfer sheet holder 7, pad unit 10, UV irradiation device 11 for complete curing, cleaning unit 12 and control unit 13.

[0061] The inkjet printer 1 is divided into four areas of a first area A1 to a fourth area A4. The first area A1 is an area where the ultraviolet curable ink is applied to the transfer sheet 6 and the ultraviolet curable ink applied to the trans...

no. 2 Embodiment approach ]

[0103] Picture 9 It is a figure which shows the schematic structure of the inkjet printer of 2nd Embodiment. Picture 10 Yes Picture 9 The schematic configuration diagram of the inkjet printer shown. Such as Picture 9 with Picture 10 As shown, the inkjet printer 21 is basically the same as the first embodiment, and includes an inkjet head 2, an ultraviolet irradiation device 3 for temporary curing, a print head unit 4 equipped with an inkjet head 2 and an ultraviolet irradiation device 3 for temporary curing, and The medium holding portion 5 for holding the medium M, the transfer sheet unit holding portion 9 for holding the transfer sheet unit 8 with the transfer sheet 6 mounted in the transfer sheet holder 7, the pad unit 10, the ultraviolet light for complete curing The irradiation device 11, the cleaning unit 12, and the control unit 13.

[0104] As in the first embodiment, the inkjet printer 21 is divided into a first area A1 to a fourth area A4. The print head unit 4 is...

no. 3 Embodiment approach

[0124] Figure 14 It is a figure which shows the schematic structure of the inkjet printer of 3rd Embodiment. Figure 15 Yes Figure 14 The schematic configuration diagram of the inkjet printer shown. Such as Figure 14 with Figure 15 As shown, the inkjet printer 31 is basically the same as the second embodiment, but is different in that it has a vacuum chamber 32 and a suction pump 33 instead of the pad unit 10. That is, the inkjet printer 31 includes an inkjet head 2, an ultraviolet irradiation device 3 for temporary curing, a print head unit 4 equipped with an inkjet head 2 and an ultraviolet irradiation device 3 for temporary curing, and a medium holding portion 5 for holding the medium M. , The transfer sheet unit holding portion 9 for holding the transfer sheet unit 8 with the transfer sheet 6 mounted in the transfer sheet holder 7, the vacuum chamber 32 connected to the suction pump 33, and the UV irradiation device 11 for complete curing , Cleaning unit 12 and control ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com