Hollow nickel molybdate nanoflower assembled by nanosheets and preparing method of hollow nickel molybdate nanoflower assembly

A technology of nickel molybdate and nanoflowers, which is applied in the direction of nanotechnology, nanotechnology, chemical instruments and methods, etc., can solve the problems of uneven size of nanorods and excessive size of nanospheres, so as to save the consumption of substrates and save Effects of raw materials and energy consumption reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] In a preferred embodiment of the present invention, also provide the preparation method of above-mentioned hollow nickel molybdate nano flower material, the steps are as follows:

[0028] (1) Add CTAB to a mixed solvent of water and ethanol to obtain a mixed solution a;

[0029] (2) Cyclohexane is added to solution a, and then ammonia water is added to obtain microemulsion b;

[0030] (3) Add Ni(NO 3 ) 2 ·6H 2 O and (NH 4 ) 6 Mo 7 o 24 , to obtain a mixed solution c;

[0031] (4) The mixed solution c prepared in step (3) is subjected to a hydrothermal reaction, the conditions of the hydrothermal reaction: the temperature is 100-125°C, and the time is 12-17h;

[0032](5) The product after step (4) is separated, washed, dried, ground, and calcined to obtain a hollow nickel molybdate nanoflower material assembled from nanosheets.

[0033] In step (2) of the present invention, preferably, after adding ammonia water, stir for 1-2h (more preferably 1.5h): to obtain a...

Embodiment 1

[0041] Put a 100mL beaker on a magnetic stirrer, add a mixed solution of 25mL distilled water and 15mL ethanol and raise the temperature to 35°C, add 0.08g CTAB to the mixed solution, when the solution is mixed and transparent, slowly add 4mL cyclohexane, and stir until well mixed. Then add 0.50mL of ammonia water, stir and react for 1.5h, slowly add 0.5718g Ni(NO 3 ) 2 ·6H 2 O and 0.3388g (NH 4 ) 6 Mo 7 o 24 , Stir the reaction at 35°C for 3h to obtain a light green solution. The obtained light green solution was transferred to a 100mL reactor, and placed in a 100°C thermostat for hydrothermal reaction for 12h. After cooling, the light green solution was suction filtered and washed. The washed precipitate was dried at 40° C. for 18 hours, and the dried precipitate was ground and then calcined at 500° C. for 4 hours to obtain hollow nickel molybdate nanoflowers assembled from nanosheets.

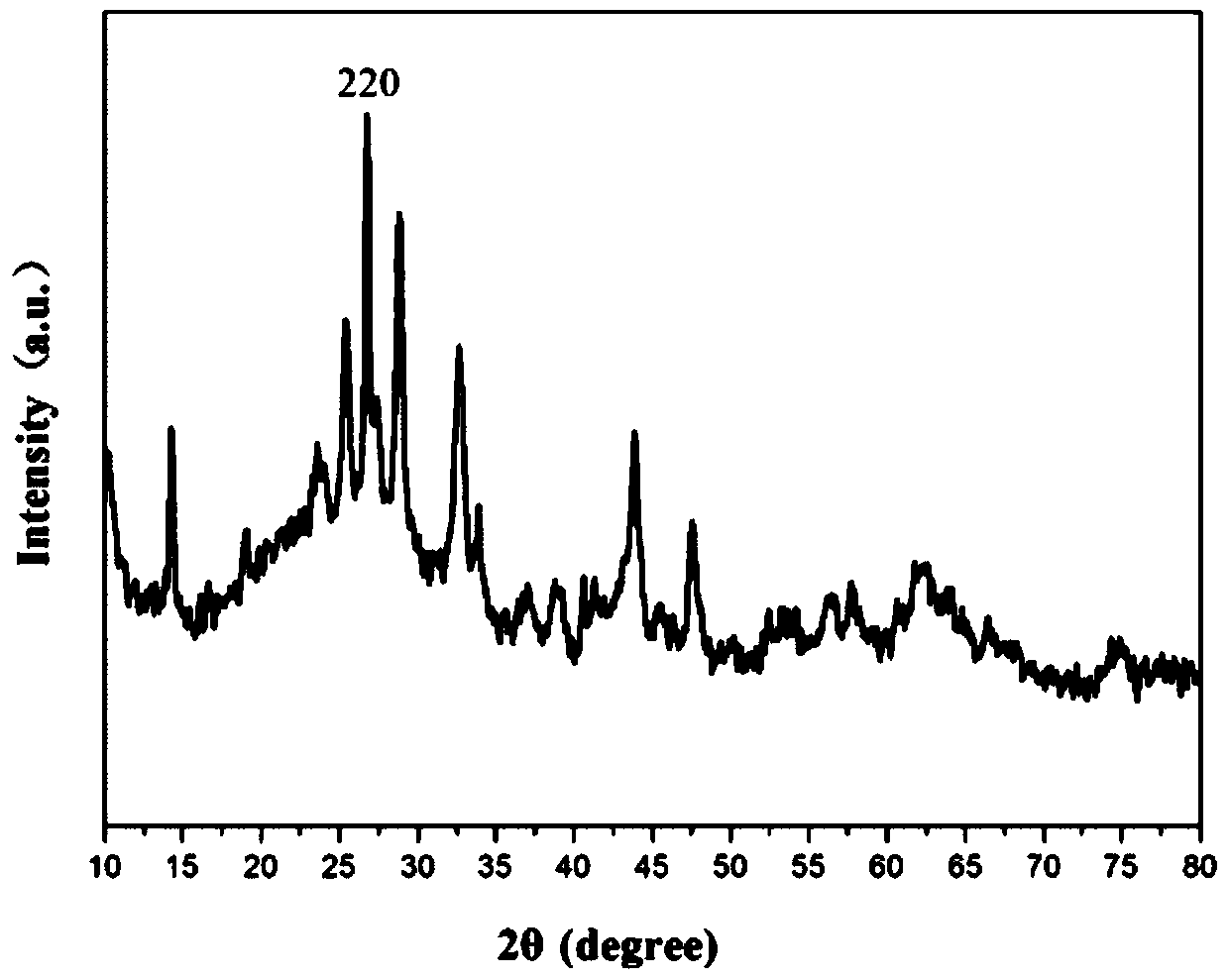

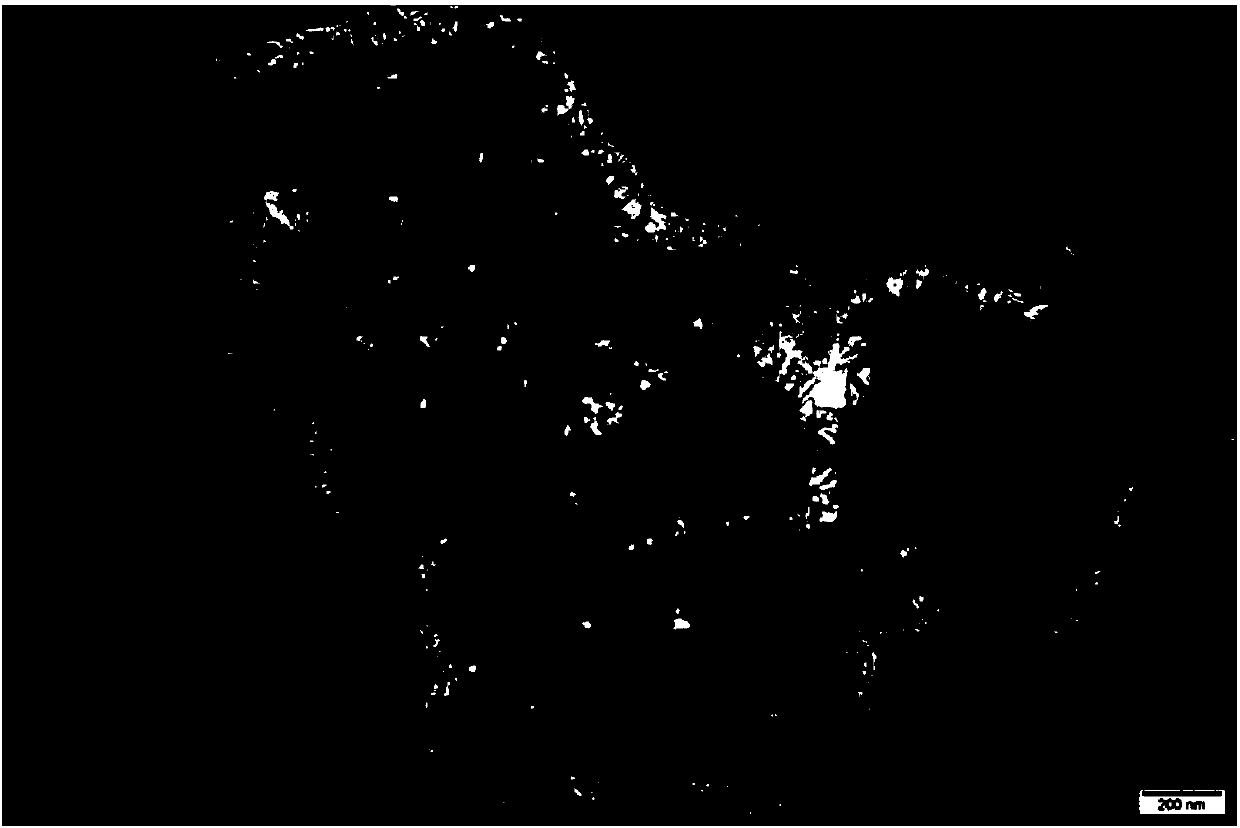

[0042] Observation by transmission electron microscope, such as figure 2 As s...

Embodiment 2

[0044] Put a 100mL beaker on a magnetic stirrer, add a mixed solution of 25mL distilled water and 15mL ethanol and raise the temperature to 35°C, add 0.08g CTAB to the mixed solution, when the solution is mixed and transparent, slowly add 4mL cyclohexane, and stir until well mixed. Then add 0.50mL of ammonia water, stir and react for 1.5h, slowly add 0.5718g Ni(NO 3 ) 2 ·6H 2 O and 0.3388g (NH 4 ) 6 Mo 7 o 24 , Stir the reaction at 35°C for 3h to obtain a light green solution. The obtained light green solution was transferred to a 100mL reactor, and placed in a 100°C thermostat for hydrothermal reaction for 18h. After cooling, the light green solution was suction filtered and washed. The washed precipitate was dried at 40°C for 18h, ground and calcined at 500°C for 4h to obtain solid nickel molybdate nanoflowers assembled from nanosheets, as shown in Figure 4 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com