A preparation method of magnetic hollow carbon nanospheres with high adsorption performance

A carbon nanosphere, high adsorption technology, applied in chemical instruments and methods, adsorption water/sewage treatment, other chemical processes, etc., can solve the problems of complex operation and high energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

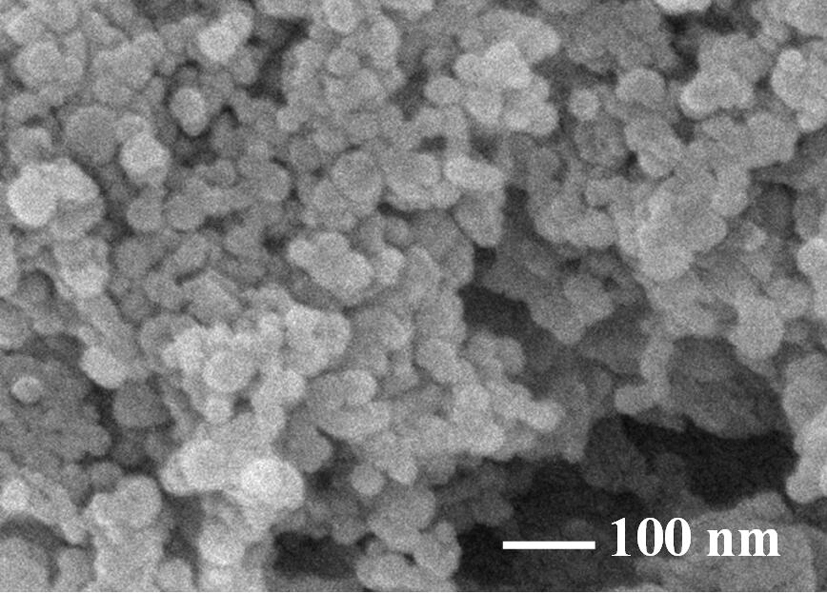

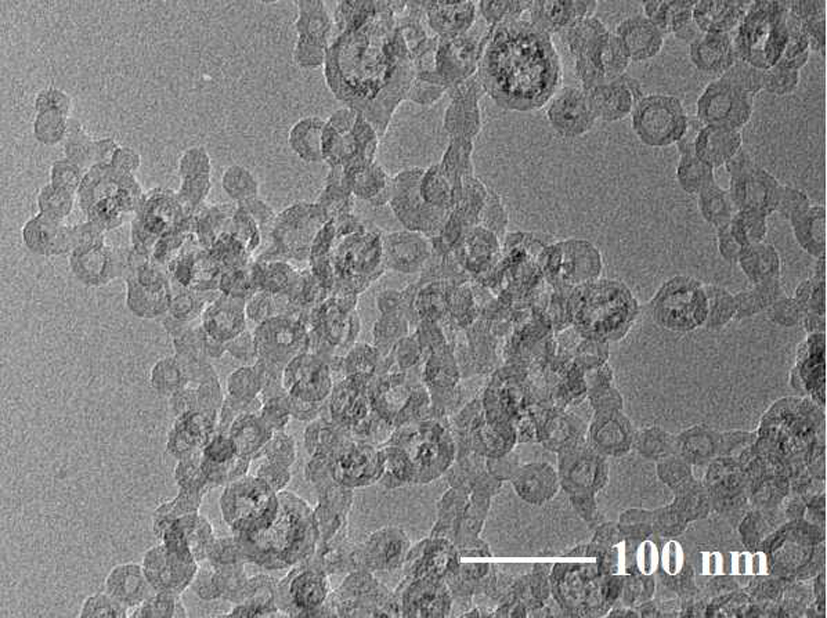

Embodiment 1

[0030] Weigh 0.1 g of 1,5-dihydroxynaphthalene and add it to 20 mL of solvent toluene, then add 0.3 g of ferrocene, 0.5 g of P123, and 1 mL of hydrogen peroxide with a mass fraction of 30% to prepare a mixed solution, and add it to a microwave reaction tube with a specification of 30 mL.

[0031] Add magnetons into the microwave reaction tube containing the mixed solution, place the microwave reaction tube in the microwave reactor, heat to 210° C. under stirring for 75 seconds, stop heating, and cool to room temperature. Transfer the mixed solution to a centrifuge tube, centrifuge at 8000r / min for 5min, and collect the precipitate.

[0032] Add 40 mL of absolute ethanol to the precipitate, centrifuge at 8000 r / min for 5 min, collect the precipitate, wash with absolute ethanol, and repeat the washing 3 times.

[0033] Add 40 mL of deionized water to the precipitate, centrifuge at 8000 r / min for 5 min, wash the precipitate, and repeat the above washing process until the centrifu...

Embodiment 2

[0042] Weigh 0.08g of 1,5-dihydroxynaphthalene, add 15mL solvent toluene, add ferrocene 0.2g, P123 0.3g, 30% hydrogen peroxide 0.8mL to make a mixed solution, add it into a 30mL microwave reaction tube, and add magneton , placed in a microwave reactor for heating and stirring, when heated to 215°C for 83s, stop heating and cool to room temperature. Afterwards, the method in Example 1 was followed to prepare magnetic hollow carbon nanospheres with a particle size of about 40 nm and regular shapes.

Embodiment 3

[0044] Weigh 0.12g of 1,5-dihydroxynaphthalene, add it to 20mL solvent toluene, add ferrocene 0.25g, P1230.4g, 30% hydrogen peroxide 0.9mL to prepare a mixed solution, add it to a 30mL microwave reaction tube, and add a magnetic Place the child in a microwave reactor for heating and stirring. When heating to 220°C for 90s, stop heating and cool to room temperature. Afterwards, the method in Example 1 was followed to prepare magnetic hollow carbon nanospheres with a particle size of about 40 nm, and the particle size was uniform.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com