Preparation method of ZnSnO3 hollow nanofibers

A hollow nano-fiber technology, applied in nanotechnology, fiber processing, hollow filament manufacturing, etc., can solve the problems of poor efficiency and cycle performance, achieve long cycle life, high specific capacity, and reduce performance degradation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] A kind of ZnSnO for lithium ion battery 3 The preparation method of hollow nanofiber comprises the following steps:

[0023] a, 0.3g tin protochloride and 0.1812g zinc chloride are dissolved in the mixed solution of 6g dehydrated alcohol and 4g DMF, then add 1g PVP wherein, obtain the required spinning solution of electrospinning;

[0024] b. Preparation of ZnCl by electrospinning 2 / SnCl 2 / PVP precursor fiber, the voltage is 20kV, the solution injection speed is 0.4ml / h, the spinning speed is 90r / min, the receiving distance is 15cm, and the electrospinning temperature is 20°C;

[0025] c. After drying the obtained fibers at 80°C for 12 hours, in a box-type resistance furnace, heat up to 650°C at a heating rate of 2°C / min for sintering for 2 hours, and then cool at a cooling rate of 1°C / min to obtain ZnSnO 3 Hollow nanofibers.

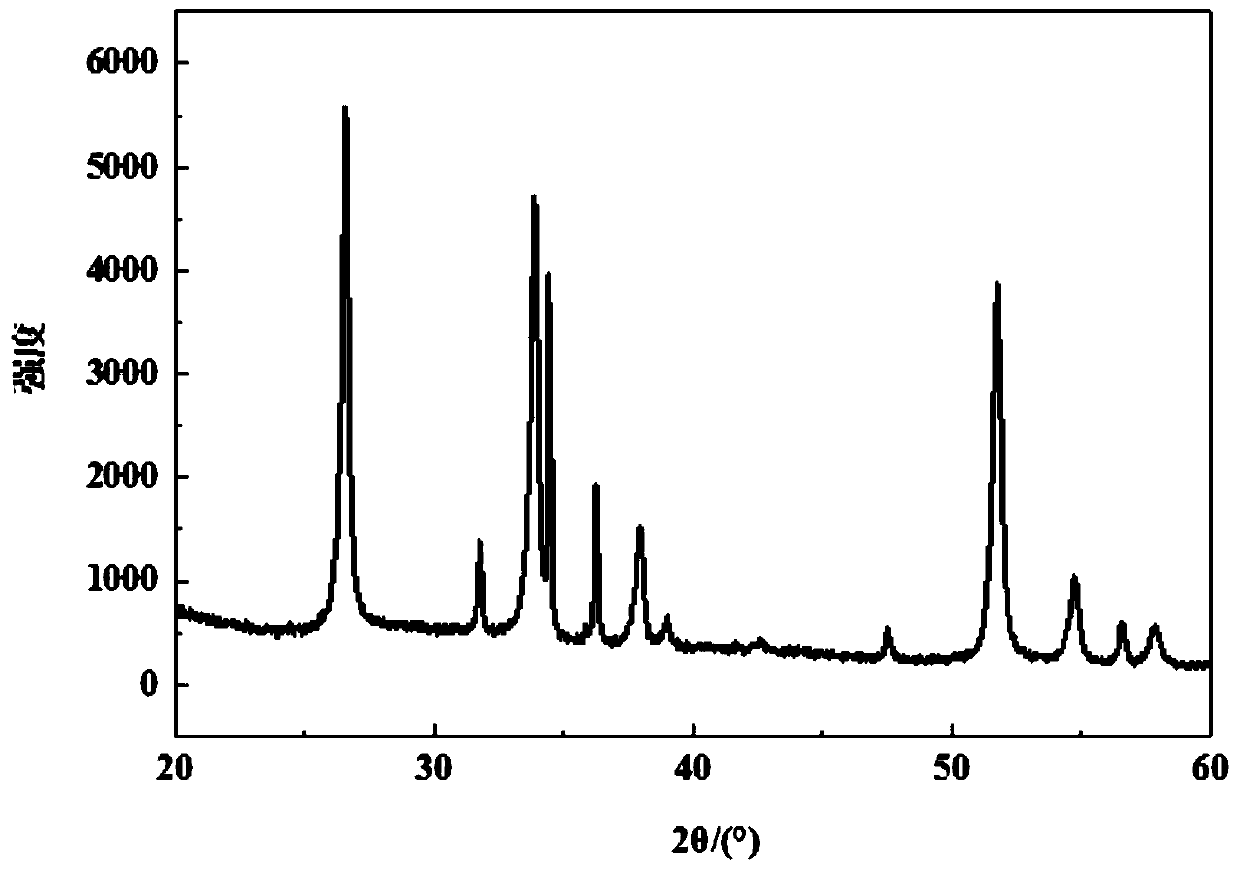

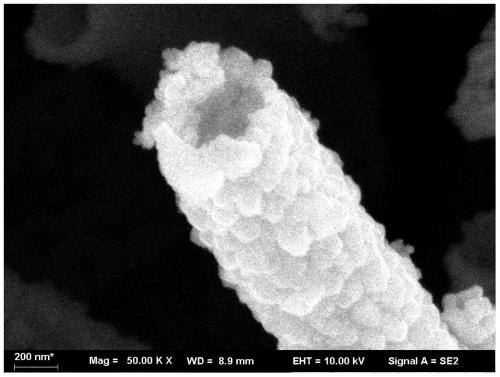

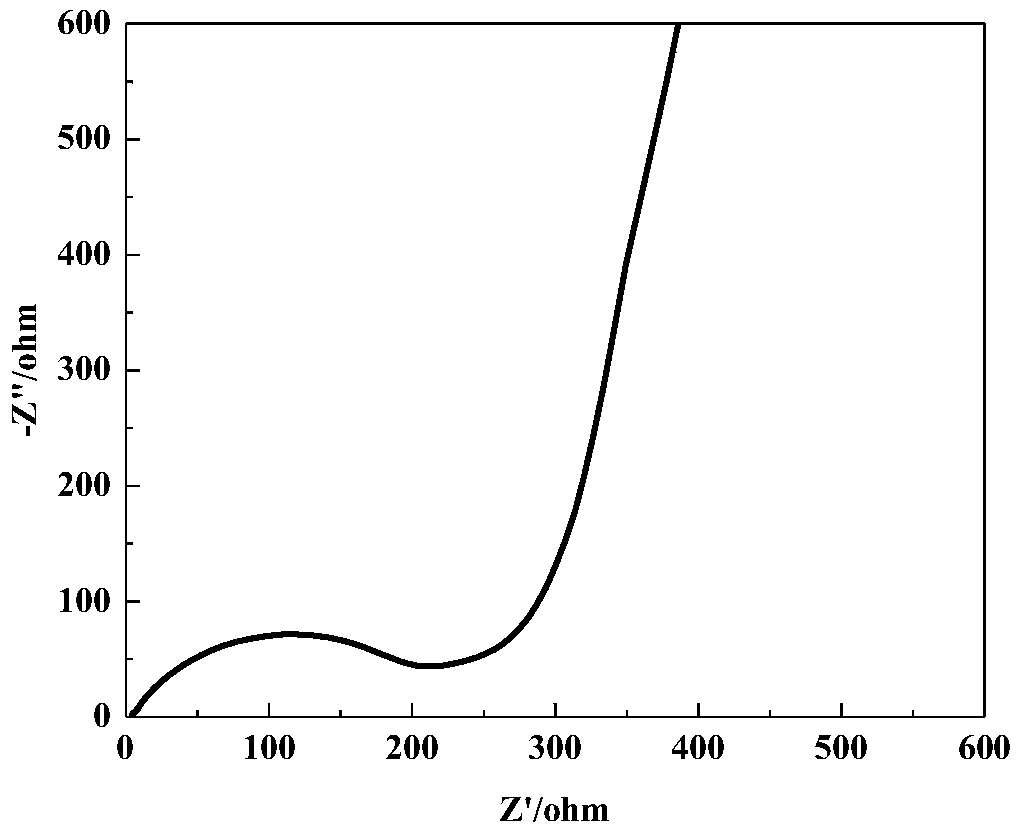

[0026] With the ZnSnO that embodiment 1 makes 3 Hollow nanofibers were detected by XRD and microscopic morphology analysis. Depend on f...

Embodiment 2

[0028] A kind of ZnSnO for lithium ion battery 3 The preparation method of hollow nanofiber comprises the following steps:

[0029] a, 0.15g stannous chloride and 0.0906g zinc chloride are dissolved in the mixed solution of 3g dehydrated alcohol and 2g DMF, then add 0.5g PVP wherein, obtain the required spinning solution of electrospinning;

[0030] b. Preparation of ZnCl by electrospinning 2 / SnCl 2 / PVP precursor fiber, the voltage is 10kV, the solution injection speed is 0.1ml / h, the spinning drum speed is 80r / min, the receiving distance is 5cm, and the electrospinning temperature is 0°C;

[0031] c. After drying the obtained fibers at 50°C for 2 hours, in a box-type resistance furnace, heat up to 500°C at a heating rate of 0.5°C / min for sintering for 2 hours, and then cool at a cooling rate of 0.5°C / min to obtain ZnSnO 3 Hollow nanofibers.

Embodiment 3

[0033] A kind of ZnSnO for lithium ion battery 3 The preparation method of hollow nanofiber comprises the following steps:

[0034] A, 1.5g stannous chloride and 0.906g zinc chloride are dissolved in the mixed solution of 21g dehydrated alcohol and 14g DMF, then add 3.5g PVP wherein, obtain the required spinning solution of electrospinning;

[0035] b. Preparation of ZnCl by electrospinning 2 / SnCl 2 / PVP precursor fiber, the voltage is 25kV, the solution injection speed is 0.6ml / h, the spinning drum speed is 300r / min, the receiving distance is 25cm, and the electrospinning temperature is 40°C;

[0036] c. After drying the obtained fibers at 120°C for 24 hours, in a box-type resistance furnace, heat up to 750°C at a heating rate of 5°C / min for sintering for 4 hours, and then cool at a cooling rate of 5°C / min to obtain ZnSnO 3 Hollow nanofibers.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com