Preparation method of molybdenum bismuth vanadate yellow pigment

A technology for bismuth molybdate vanadate and yellow pigments, applied in the field of inorganic pigments, can solve the problems of poor covering power, difficult to popularize, and high cost of pure bismuth vanadate, and achieve the effects of reducing production cost, simple production process and shortening calcination time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

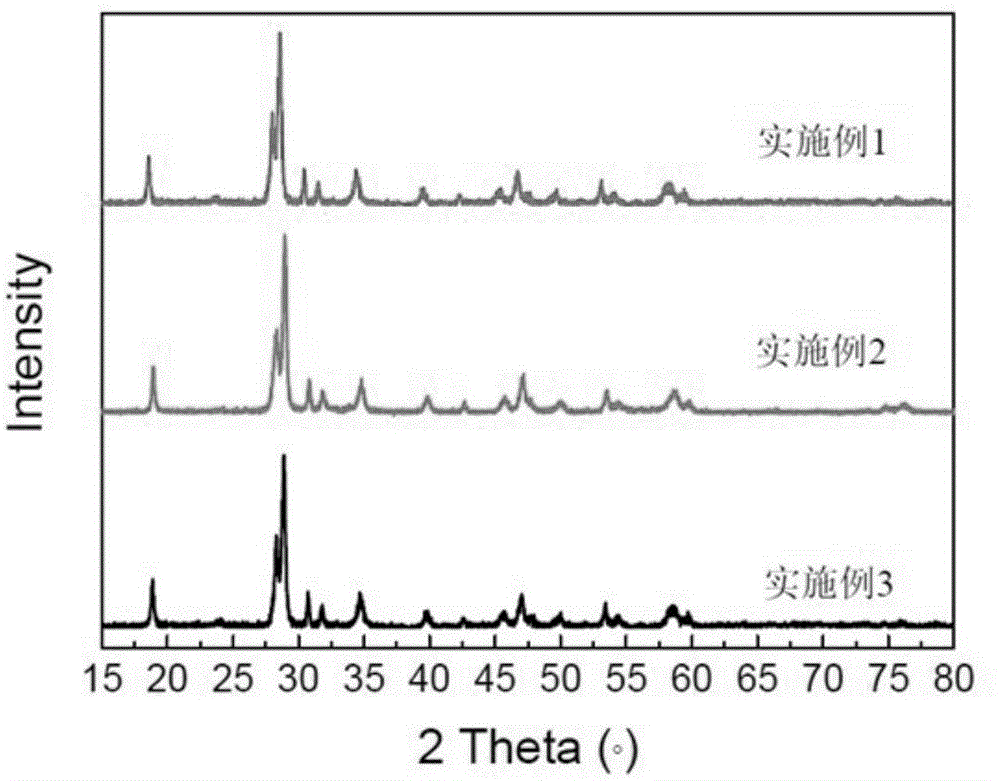

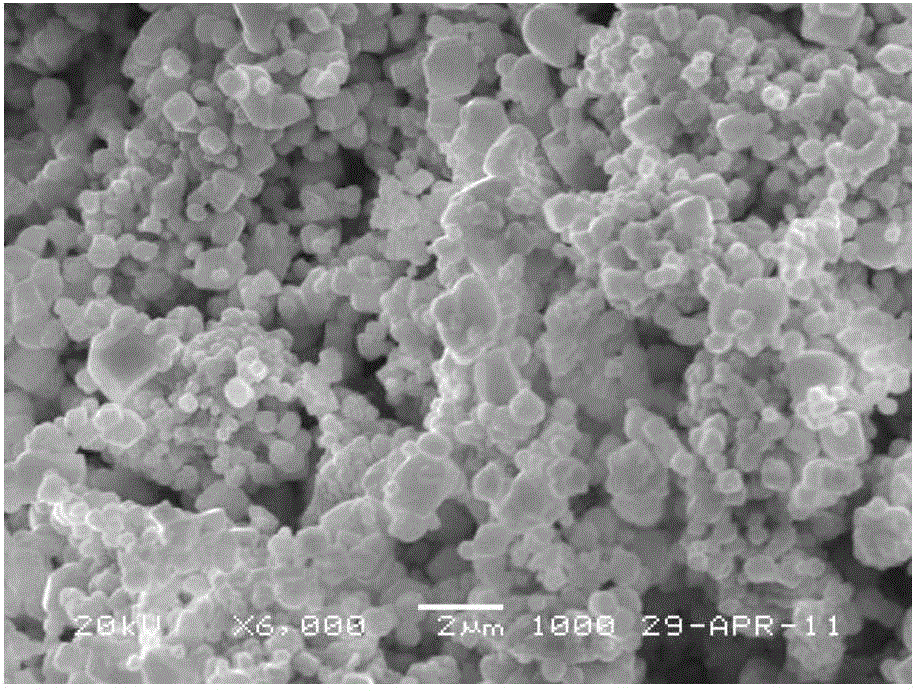

Embodiment 1

[0024] (1) Take 6.596g V 2 o 5 , 42.245g Bi 2 o 3 , 7.816g MoO 3 After mixing and milling for 30 minutes, add 92.670g NaNO 3 and 113.411g KNO 3 Continue ball milling for 10 minutes to make a powder precursor.

[0025] (2) Calcining the powder precursor obtained in step (1) in a muffle furnace at 450° C. for 5 hours in an air atmosphere.

[0026] (3) Naturally cool the material obtained in step (2) to room temperature, dissolve the nitrate in it with hot water, separate the solid sample by suction filtration, and then dry it at 100°C to obtain BiVO with a composite structure 4 0.75Bi 2 MoO 6 product.

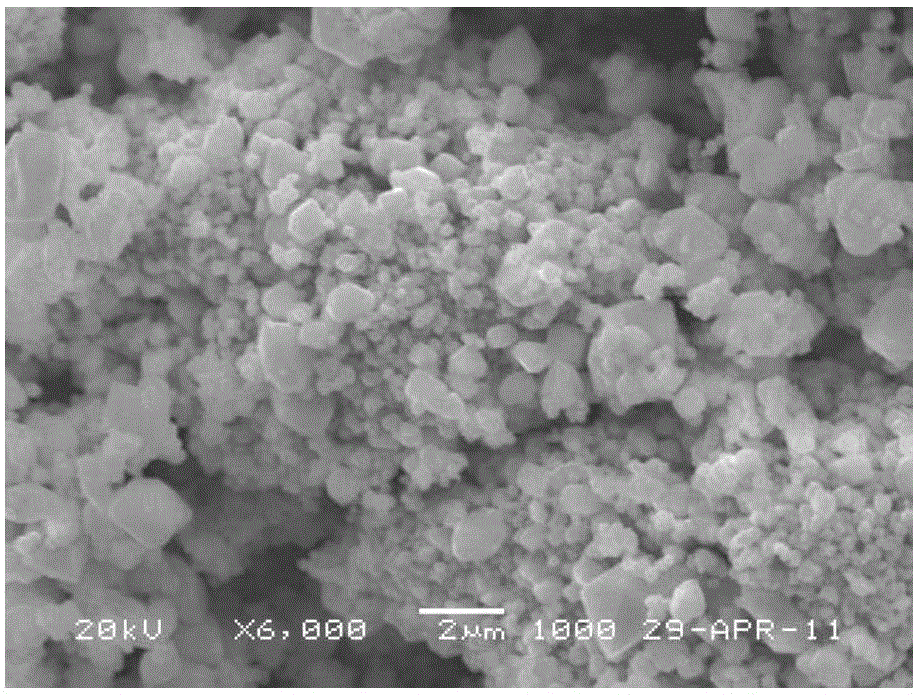

Embodiment 2

[0028] (1) Take 5.969g V 2 o 5 , 30.584g Bi 2 o 3 , 4.724g MoO 3 After mixing and milling for 20 minutes, add 33.104g LiNO 3 and 28.542g KNO 3 Continue ball milling for 10 minutes to make a powder precursor.

[0029] (2) Calcining the powder precursor obtained in step (1) in a muffle furnace at 350° C. for 10 hours in an air atmosphere.

[0030] (3) Naturally cool the material obtained in step (2) to room temperature, dissolve the nitrate in it with hot water, separate the solid sample by suction filtration, and then dry it at 90°C to obtain BiVO with a composite structure 4 0.5Bi 2 MoO 6 product.

Embodiment 3

[0032] (1) Take 11.641g V 2 o 5 , 41.749g Bi 2 o 3 , 3.685g MoO 3 After mixing and milling for 10 minutes, add 114.150g NaNO 3 , and continue ball milling for 10 minutes to make a powder precursor.

[0033] (2) Calcining the powder precursor obtained in step (1) in a muffle furnace at 400° C. for 12 hours in an air atmosphere.

[0034] (3) Naturally cool the material obtained in step (2) to room temperature, dissolve the nitrate in it with hot water, separate the solid sample by suction filtration, and then dry it at 120°C to obtain BiVO with a composite structure 4 0.2Bi 2 MoO 6 product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com