Process and device for whitening calcined black talc

A technology for calcining black talc, which is applied in magnesium silicate, silicate and other directions, can solve problems such as backward equipment and environmental pollution, and achieve the effects of improving production capacity, reducing production costs, and shortening calcination time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

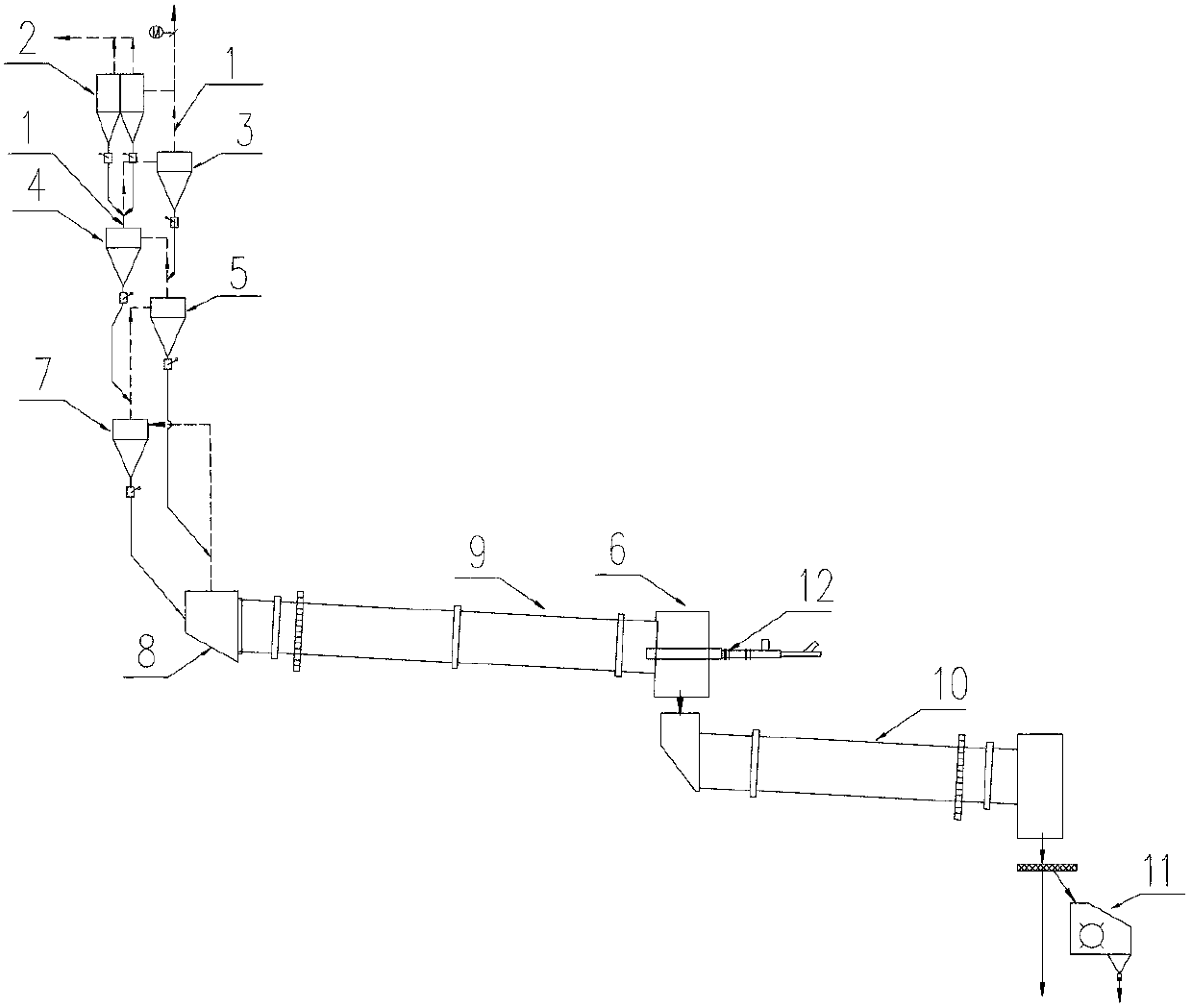

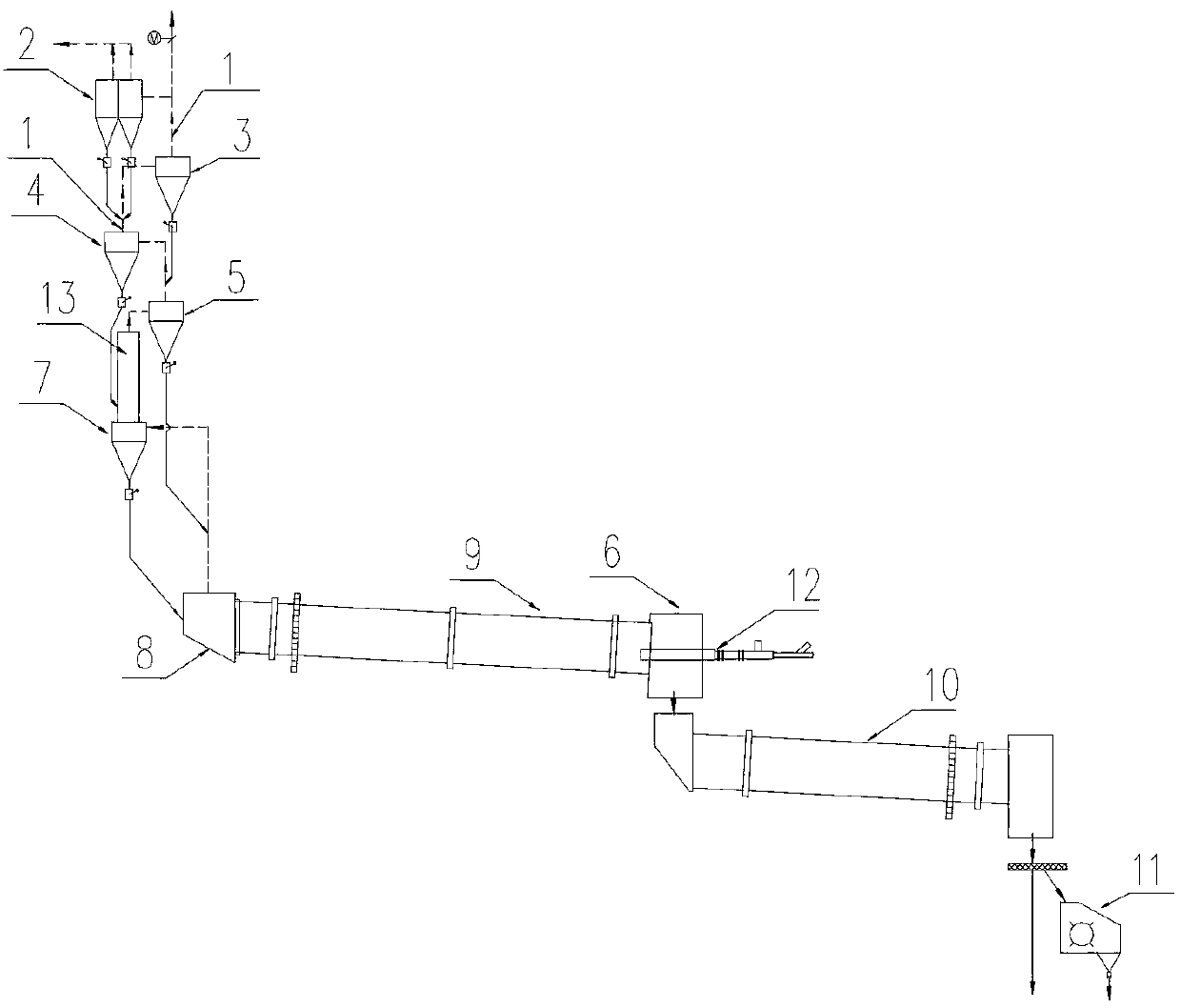

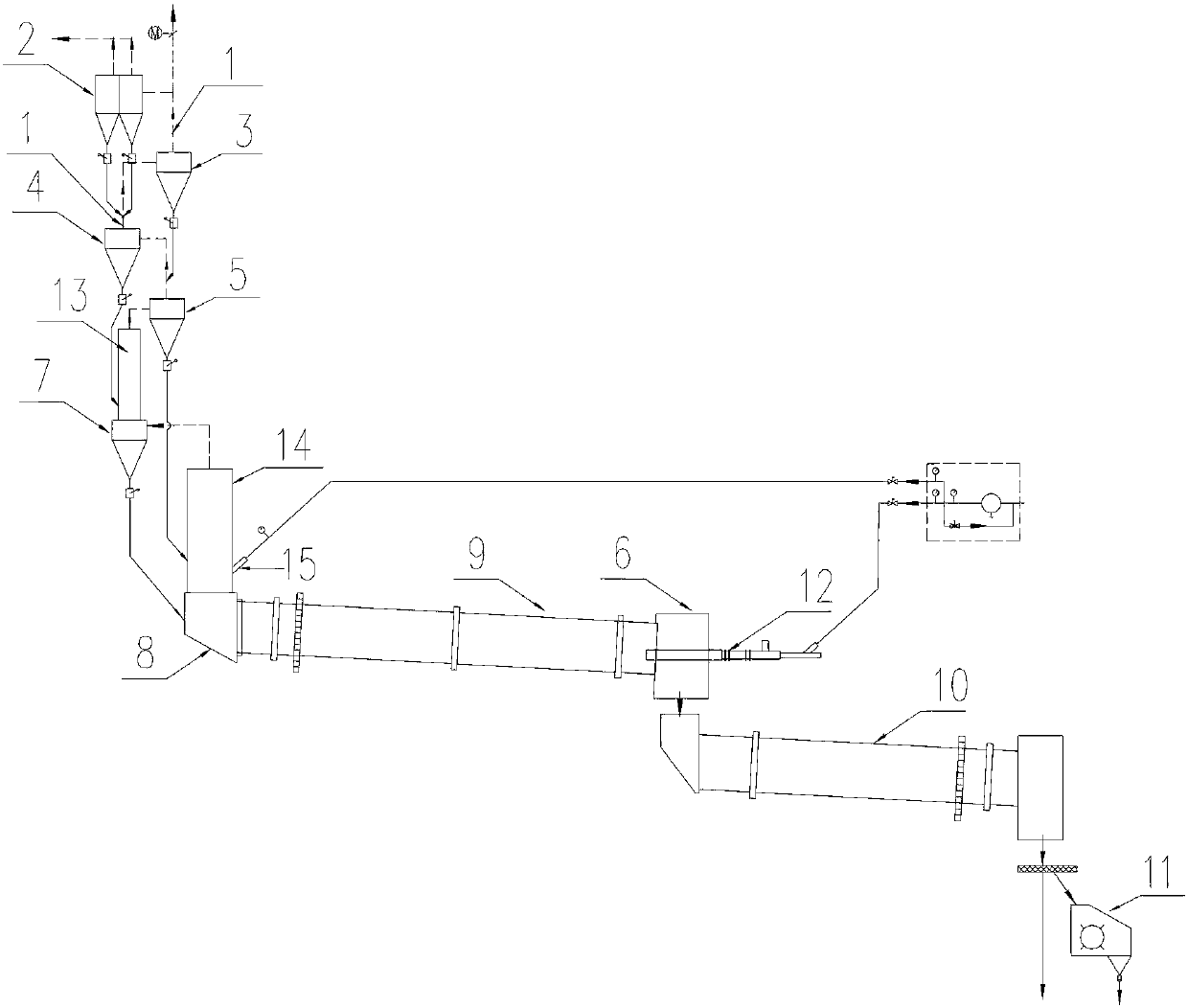

[0028] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

[0029] The invention discloses a process for whitening calcined black talc. Black talc ore is used as a raw material, and sequentially undergoes ore dressing, crushing, grinding, rotary kiln calcination and cooler cooling to obtain granular and massive whiteness greater than or equal to 90. Calcined black talc products, wherein the firing zone temperature in the rotary kiln calcination process is 800-1400°C, and the residence time of the material in the kiln is 30-90 minutes.

[0030] In this embodiment, the following steps are also included, crushing, dispersing and grading and removing iron to the cooled granular and massive calcined black talc products to obtain powdered calcined black talc products with a whiteness greater than or equal to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| whiteness | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com