Method for preparing talcose compositions comprising synthetic mineral particles containing silicon, germanium and metal

A technology of mineral particles and synthetic particles, applied in the direction of germanium compounds, silicon compounds, chemical instruments and methods, etc., can solve the problems of crystallinity and thermal stability of talc compositions that cannot be obtained

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

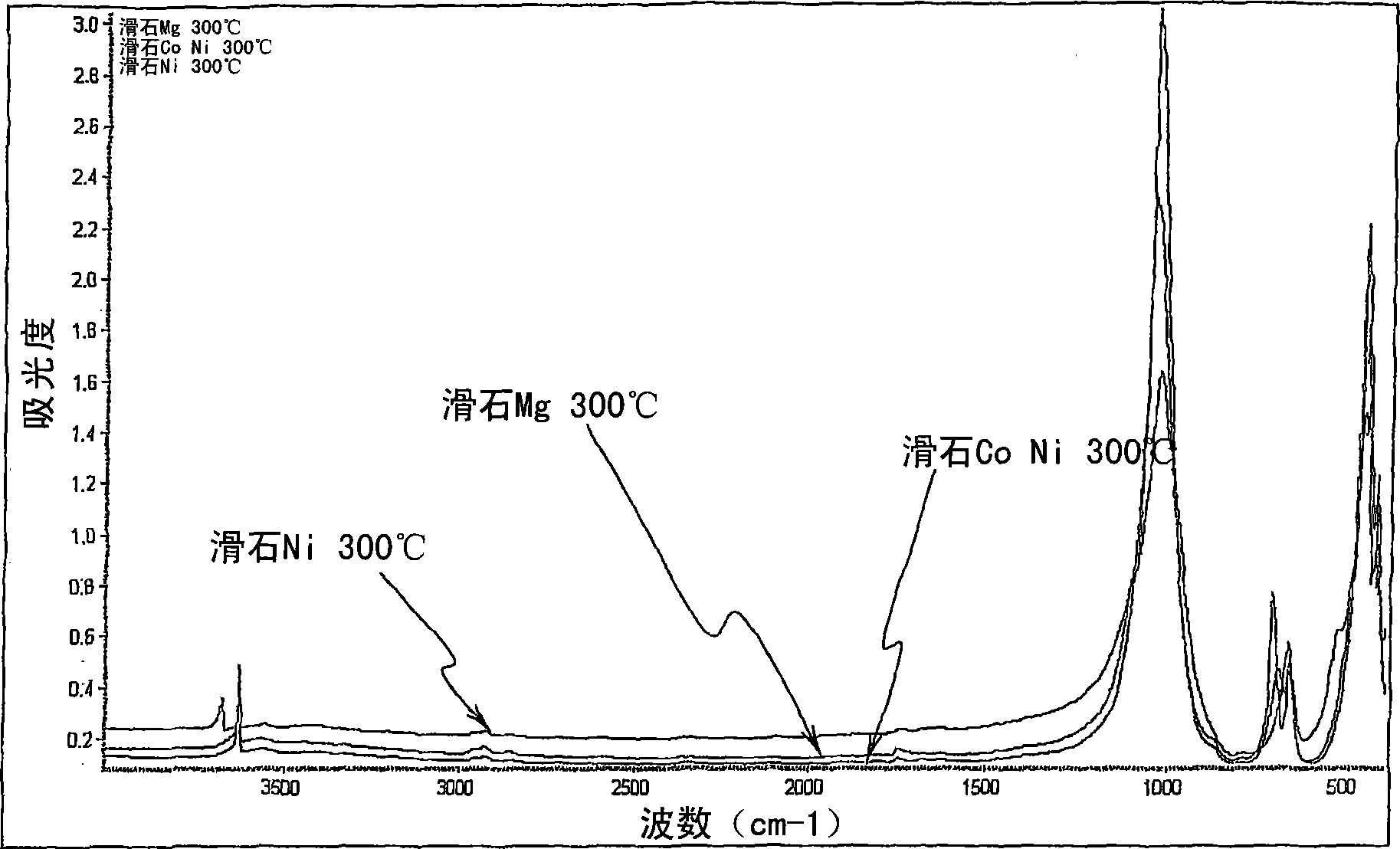

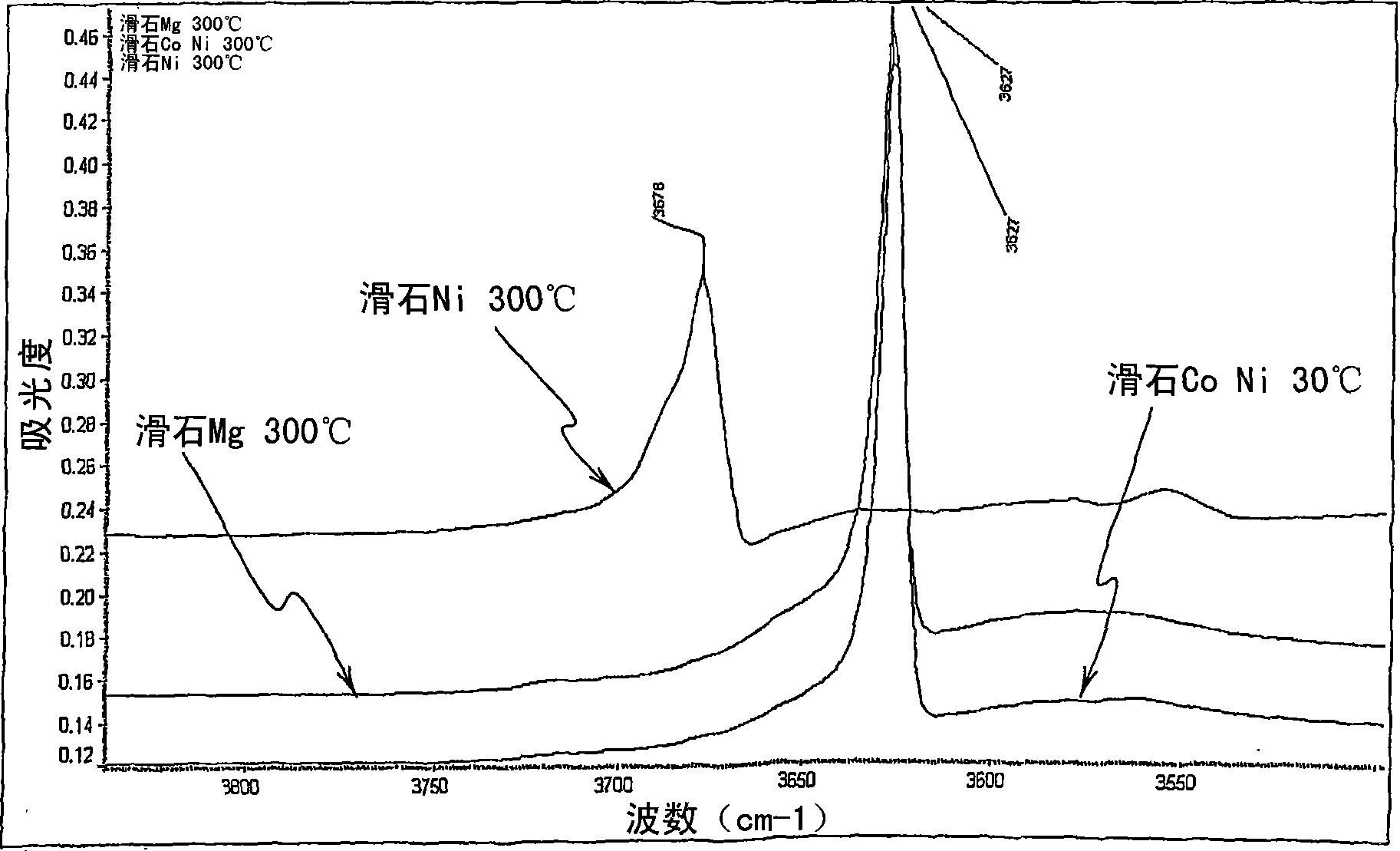

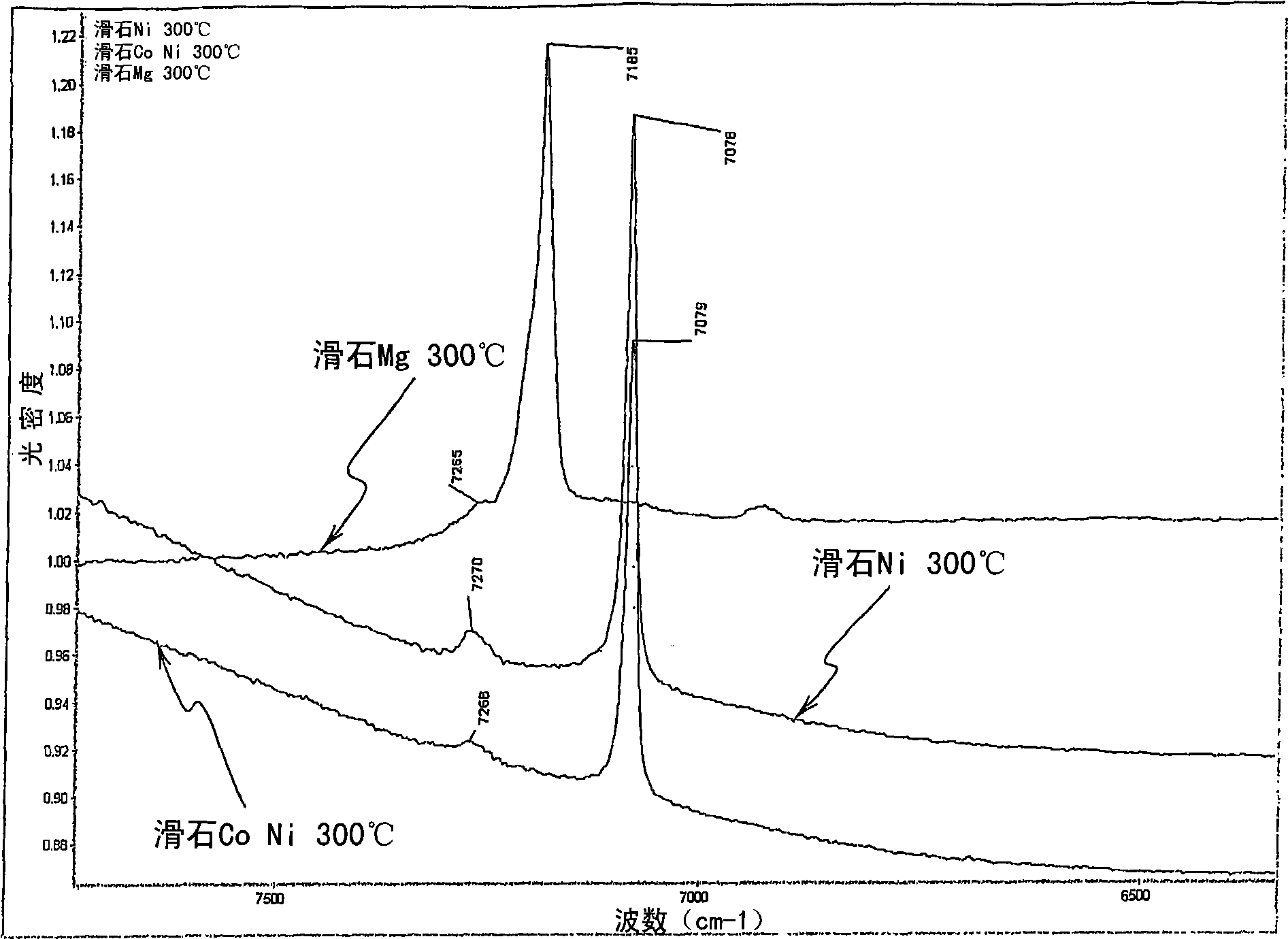

Image

Examples

Embodiment Construction

[0107]A - General scheme for the synthesis of the talc compositions of the present invention

[0108] 1- Preparation of gels containing silicon, germanium and metals

[0109] Gels containing silicon, germanium and metals are prepared by co-precipitation according to the following reaction:

[0110]

[0111] Hydrated gels containing silicon, germanium and metals with stoichiometric talc (4Si / Ge for 3M) can be obtained by the co-precipitation reaction. It starts with:

[0112] 1. An aqueous solution of sodium silicate pentahydrate or an aqueous solution of sodium germanate, or a mixture of these two solutions in a molar ratio of x:(1-x),

[0113] 2. Metal chloride solutions prepared by diluting one or more metal salts (in the form of hygroscopic crystals) in distilled water, and

[0114] 3.1N hydrochloric acid solution.

[0115] Gels containing silicon, germanium and metals were prepared according to the following scheme:

[0116] 1. The hydrochloric acid solution and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com