Preparation method of micro-nano hydroxyl magnesium silicate

A hydroxymagnesium silicate, micro-nano technology, applied in the direction of magnesium silicate, silicate, nanotechnology, etc., can solve the problem that the consistency of samples is difficult to control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The steps of a preparation method of micro-nano-scale magnesium hydroxysilicate:

[0023] a. sodium hydroxide is mixed with the aqueous solution of 1mol / L;

[0024] b. mixing nano-magnesia and nano-silicon dioxide in a container according to a molar ratio of 3: 2, and adding the sodium hydroxide solution prepared in step a, and the addition is 80% of the volume of the container. After fully mixing, move it into the reactor, and react for 72 hours at a temperature of 200°C;

[0025] c. Filter the reacted mixed solution with pure water until the filtrate is neutral, and dry the filtered filter cake at 80° C. to obtain micronano-scale magnesium hydroxysilicate powder.

[0026] Product performance testing:

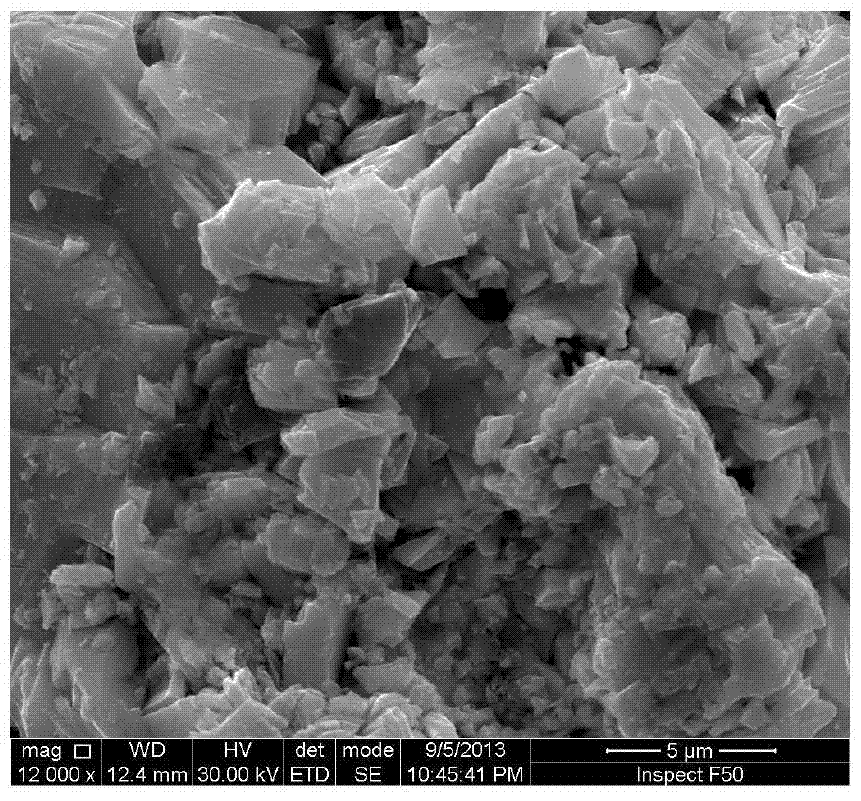

[0027] Carry out XRD and transmission electron microscope analysis detection result to the prepared micronano grade magnesium silicate powder body as follows figure 1 (SEM), Image 6 (XRD) shows.

Embodiment 2

[0029] The steps of a preparation method of micro-nano-scale magnesium hydroxysilicate:

[0030] a. Sodium hydroxide is mixed with the aqueous solution of 0.5mol / L;

[0031] b. mixing nano-magnesia and nano-silicon dioxide in a container according to a molar ratio of 1:1, and adding the sodium hydroxide solution prepared in step a, the amount of which is 60% of the volume of the container. After fully mixing, move it into the reactor, and react for 96 hours at a temperature of 180°C;

[0032] c. Filter the reacted mixed solution with pure water until the filtrate is neutral, and dry the filtered filter cake at 80° C. to finally produce micronano-scale magnesium hydroxysilicate powder.

[0033] Product performance testing:

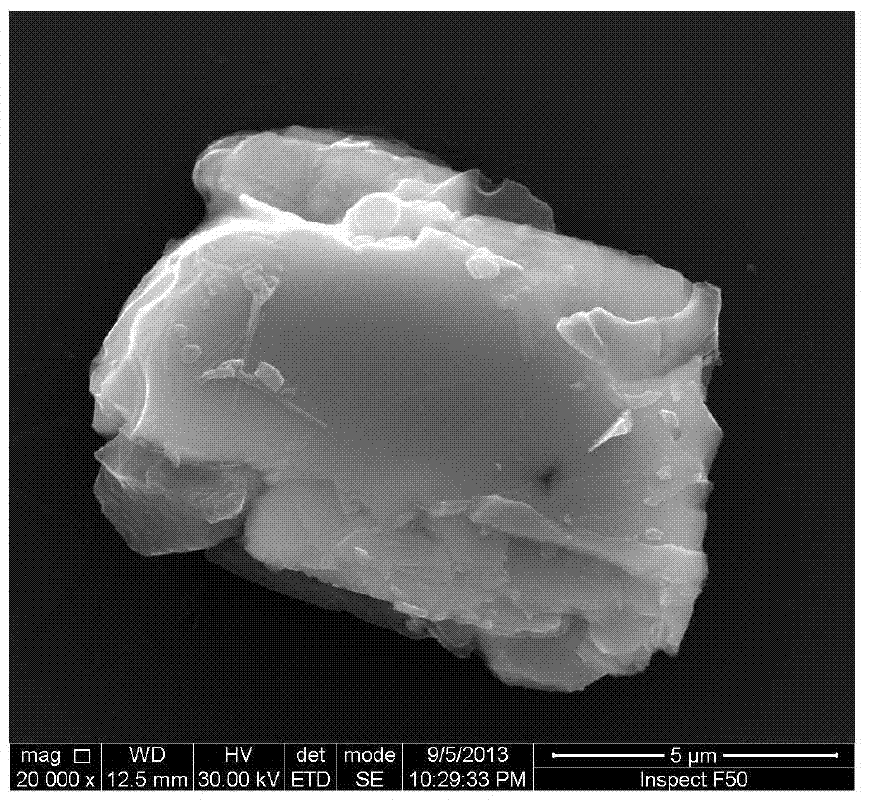

[0034] The obtained nanoscale magnesium hydroxysilicate powder was carried out by XRD and transmission electron microscopy and the detection results were as follows: figure 2 (SEM), Figure 7 (XRD) shows.

Embodiment 3

[0036] The steps of a preparation method of micro-nano-scale magnesium hydroxysilicate:

[0037] a. sodium hydroxide is mixed with the aqueous solution of 2mol / L;

[0038] b. mixing nano-magnesia and nano-silicon dioxide in a container according to a molar ratio of 4: 3, and adding the sodium hydroxide solution prepared in step a, the amount of which is 90% of the volume of the container. After fully mixing, move it into the reactor, and react for 48 hours at a temperature of 220°C;

[0039] c. Filter the reacted mixed solution with pure water until the filtrate is neutral, and dry the filtered filter cake at 80° C. to finally produce micronano-scale magnesium hydroxysilicate powder.

[0040] Product performance testing:

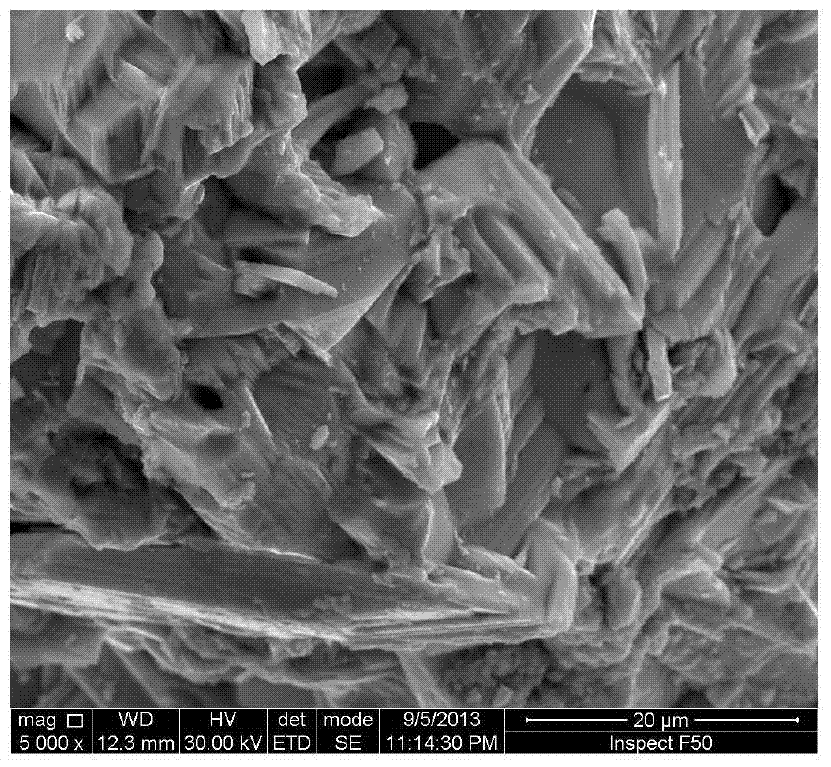

[0041] The obtained nanoscale magnesium hydroxysilicate powder was carried out by XRD and transmission electron microscopy and the detection results were as follows: image 3 (SEM), Figure 8 (XRD) shows.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com