Method for purifying low-grade sepiolite

A purification method and technology of sepiolite, applied in magnesium silicate, silicate and other directions, can solve the problems of complex production process, long production cycle, low product grade, etc., to avoid ore pollution, short process and cycle, simple craftsmanship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

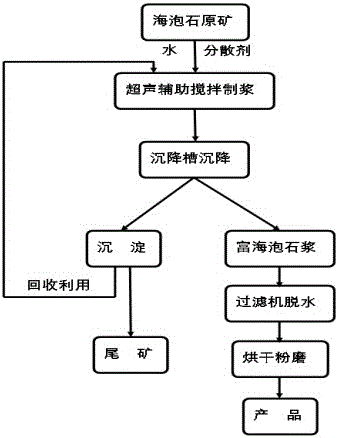

Image

Examples

Embodiment 1

[0027] The steps of this embodiment are as follows:

[0028] (1) Weigh 5.00g of sepiolite raw ore with a sepiolite content of about 30%, a total of 2 samples, marked as 1 and 1#, of which 1 is the control group without ultrasound, and 1# is the ultrasound group. Add water to the above samples according to the solid-liquid ratio of 1:8, and let the sepiolite fully absorb water and swell for more than 12 hours;

[0029] (2) Add the above samples with 0.2% sodium hexametaphosphate as a dispersant, stir at 400rpm for 3h, and ultrasonicate the experimental group for 20min in an ultrasonic instrument with an ultrasonic frequency of 40KHz and a sound intensity of 40w / cm 2 , and then the sample was left to stand for 1h; the control group was not ultrasonicated;

[0030] (3) Take out the suspension of the upper layer, centrifuge at 900 rpm for 5 minutes, discard the upper layer of water, dry the lower layer at 108°C for 24 hours, and grind to obtain the product.

[0031] The sepiolit...

Embodiment 2

[0033] The steps of this embodiment are as follows:

[0034] (1) Weigh 5g of raw sepiolite with a content of 20%, 2 samples in total, marked as 2 and 2#, of which 2 is the control group without ultrasound, and 2# is the ultrasound group. Add water to the above samples according to the solid-to-liquid ratio of 1:14, and let the sepiolite fully absorb water and swell after standing for more than 12 hours;

[0035] (2) Add the above samples with 0.3% sodium hexametaphosphate as a dispersant, stir at 300rpm for 3h, and ultrasonicate the experimental group for 20min in an ultrasonic instrument with an ultrasonic frequency of 40KHz and a sound intensity of 30w / cm 2 , and then the sample was left to stand for 4h; the control group was not ultrasonicated;

[0036] (3) Take out the suspension of the upper layer, centrifuge at 900 rpm for 5 minutes, discard the upper layer of water, dry the lower layer at 108°C for 24 hours, and grind to obtain the product.

[0037] The sepiolite prod...

Embodiment 3

[0039] In this example, water is added to the raw ore, dispersant is added to the pulp, and pulp is made under the combined action of mechanical stirring, ultrasonic assistance and dispersant dispersion; then sedimentation to obtain sepiolite-rich pulp ore; pulp vacuum filter dehydration, drying, and grinding To obtain the product, the concrete process steps are as follows:

[0040] Sepiolite pulping: the sepiolite raw ore selected has a sepiolite content of about 31%, and the remaining components are talc, quartz, calcite, etc. Add raw sepiolite and water into the stirring tank according to the solid-to-liquid ratio of 1:10, add a mixture of sodium hexametaphosphate and sodium pyrophosphate with a solid mass of 0.2% as a dispersant, turn on the ultrasonic generator, and the ultrasonic frequency is 5000KHz. The strength is 75w / cm 2. Turn on the mixer and continue to stir to prepare the ore slurry, the stirring speed is 400rpm, and the stirring time is 60min;

[0041] Purifi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com