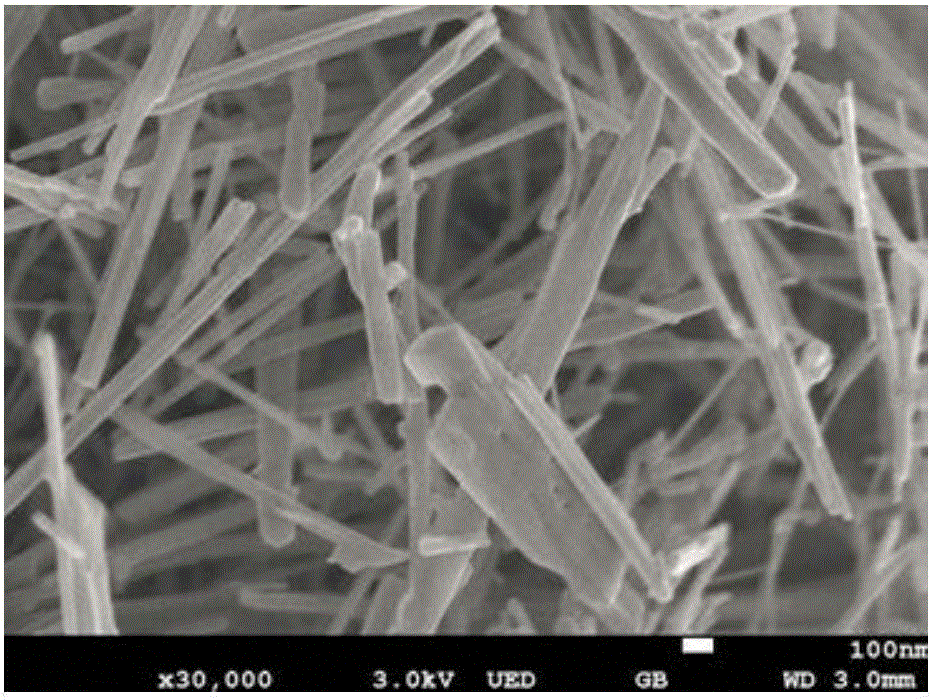

Fibrous nano silicate concrete admixture and preparation method thereof

A concrete admixture, nano-silicate technology, applied in the direction of silicate, alkaline earth metal silicate, magnesium silicate, etc., can solve the problems of high brittleness, poor crack resistance, slow development of concrete strength, etc., and achieve toughness Improving and enhancing the effect of early strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

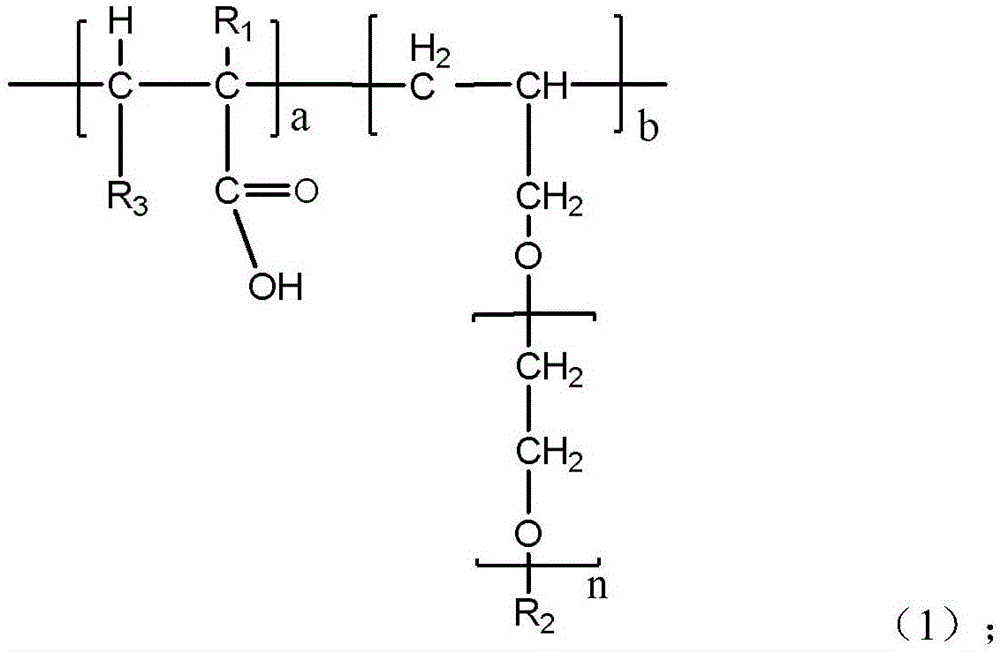

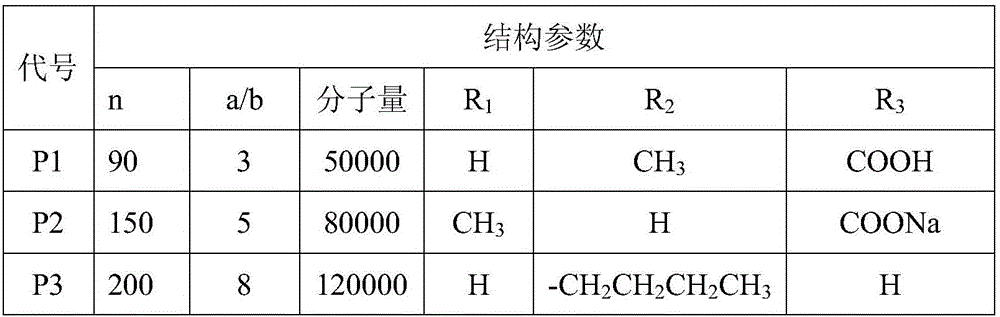

[0029] (1) Preparation of fibrous nano-magnesium silicate suspension

[0030] In a 500ml three-necked flask, make a base with the aqueous solution of the polymer dispersant, add 20% magnesium silicate and 20% sodium silicate aqueous solution dropwise to the continuously stirring polymer solution simultaneously, and control the reaction temperature to 80-90°C, the dropping time is 5-8h. Concrete preparation embodiment sees table 3:

[0031] The preparation of table 3 nanometer magnesium silicate suspension

[0032]

[0033] (2) Preparation of fibrous nano silicate admixture

[0034] Under the condition of 20 DEG C, the soluble calcium salt and the soluble silicate solution are added dropwise to the above-mentioned fibrous nano-magnesium silicate suspension diluted with water ( In NM), the dropping time should be controlled within 4-6 hours to obtain a fibrous nano silicate suspension concrete admixture with a solid content of 5-10%. The specific preparation example is sh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com