Preparation method of silicate nano hollow structure material

A hollow structure, silicate technology, applied in nanostructure manufacturing, silicate, magnesium silicate and other directions, can solve the problems of time-consuming, expensive template particle removal, complicated soft template preparation, etc., to achieve high ion exchange performance, The effect of good exchange adsorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] The preparation method of the present embodiment comprises the following steps:

[0016] 1. In the mixed solution of ethanol and polyethylene glycol, add 0.2 mol / L magnesium nitrate solution and 0.2 mol / L sodium silicate solution successively to form a mixed solution, in which ethanol, polyethylene glycol, The volume fractions of magnesium nitrate solution and sodium silicate solution are 30 parts, 3 parts, 1 part and 1 part respectively;

[0017] 2. Add 4mol / L NaOH solution to the mixed solution prepared in step 1, the ratio of NaOH solution to the nitrate solution in step 1 is 1:0.03 by volume and fraction, after magnetic stirring for 15min, transfer to the hydrothermal still, at 190 React under hydrothermal conditions for 12 h, filter and dry to obtain magnesium silicate core-shell microspheres.

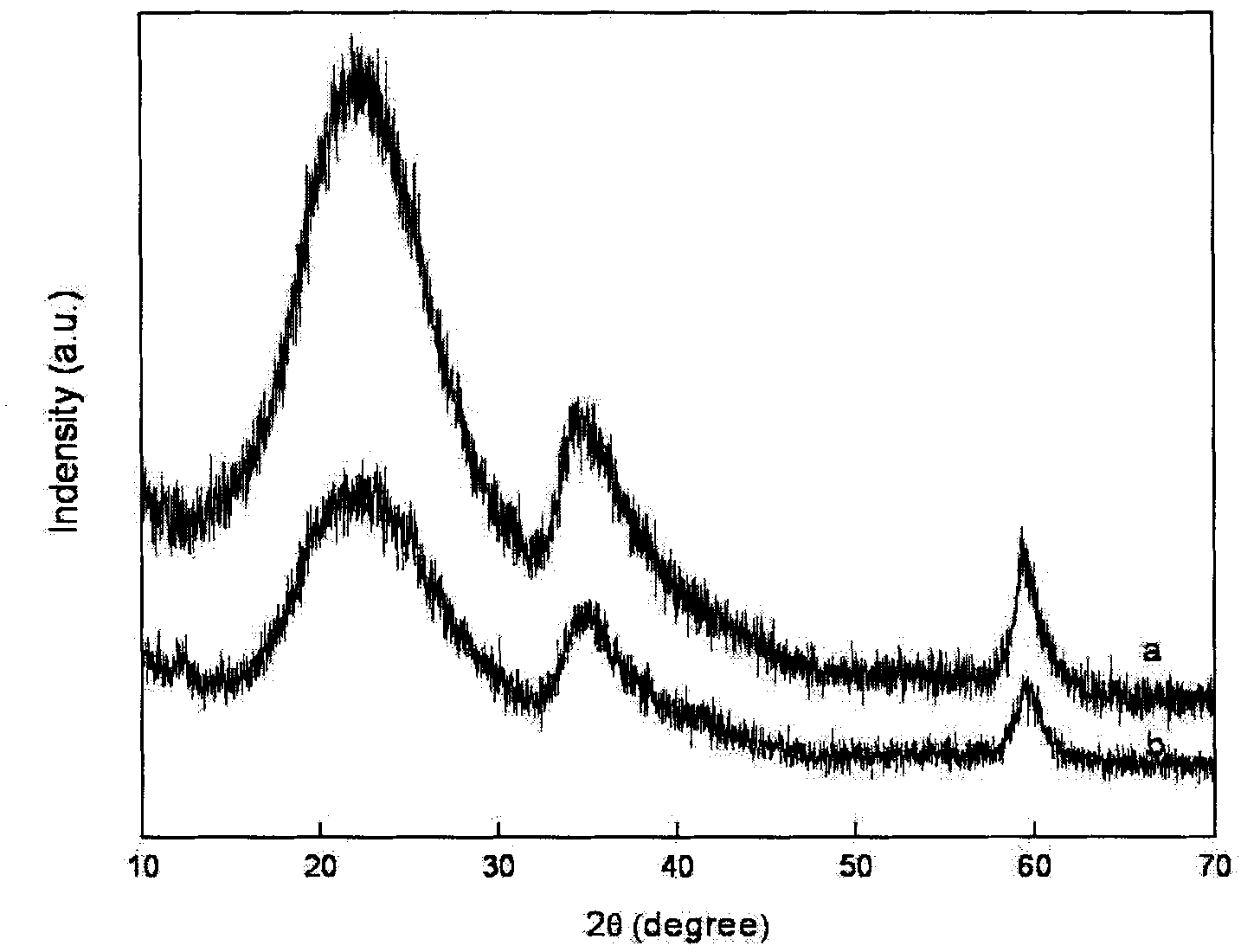

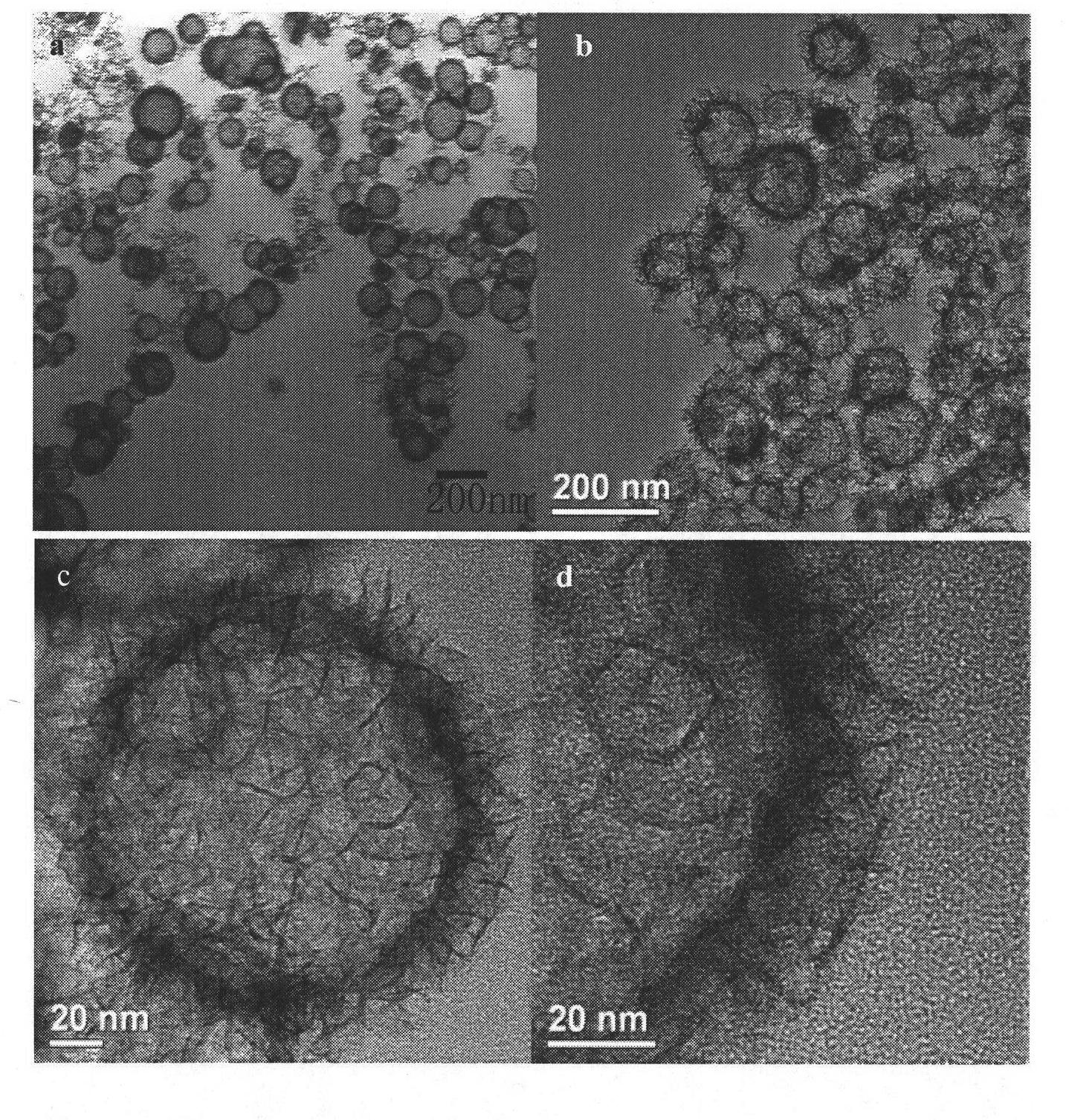

[0018] figure 1 Middle: curve b is the XRD characterization of the core-shell sphere product prepared in Example 1, the main diffraction peaks 2θ=19.493, 24.366, 35.307 a...

Embodiment 2

[0021] The preparation method of the present embodiment comprises the following steps:

[0022] 1. In the mixed solution of ethanol and polyethylene glycol, add 0.2 mol / L magnesium nitrate solution and 0.2 mol / L sodium silicate solution successively to form a mixed solution, in which ethanol, polyethylene glycol, The volume fractions of magnesium nitrate solution and sodium silicate solution are 30 parts, 3 parts, 1 part and 1 part respectively;

[0023] 2. Add 4mol / L NaOH solution to the mixed solution prepared in step 1, the ratio of NaOH solution to the nitrate solution in step 1 is 1:0.1 by volume, and after magnetic stirring for 15min, transfer to the hydrothermal kettle, and at 190 React under hydrothermal conditions for 12 h, filter and dry to obtain magnesium silicate hollow microspheres.

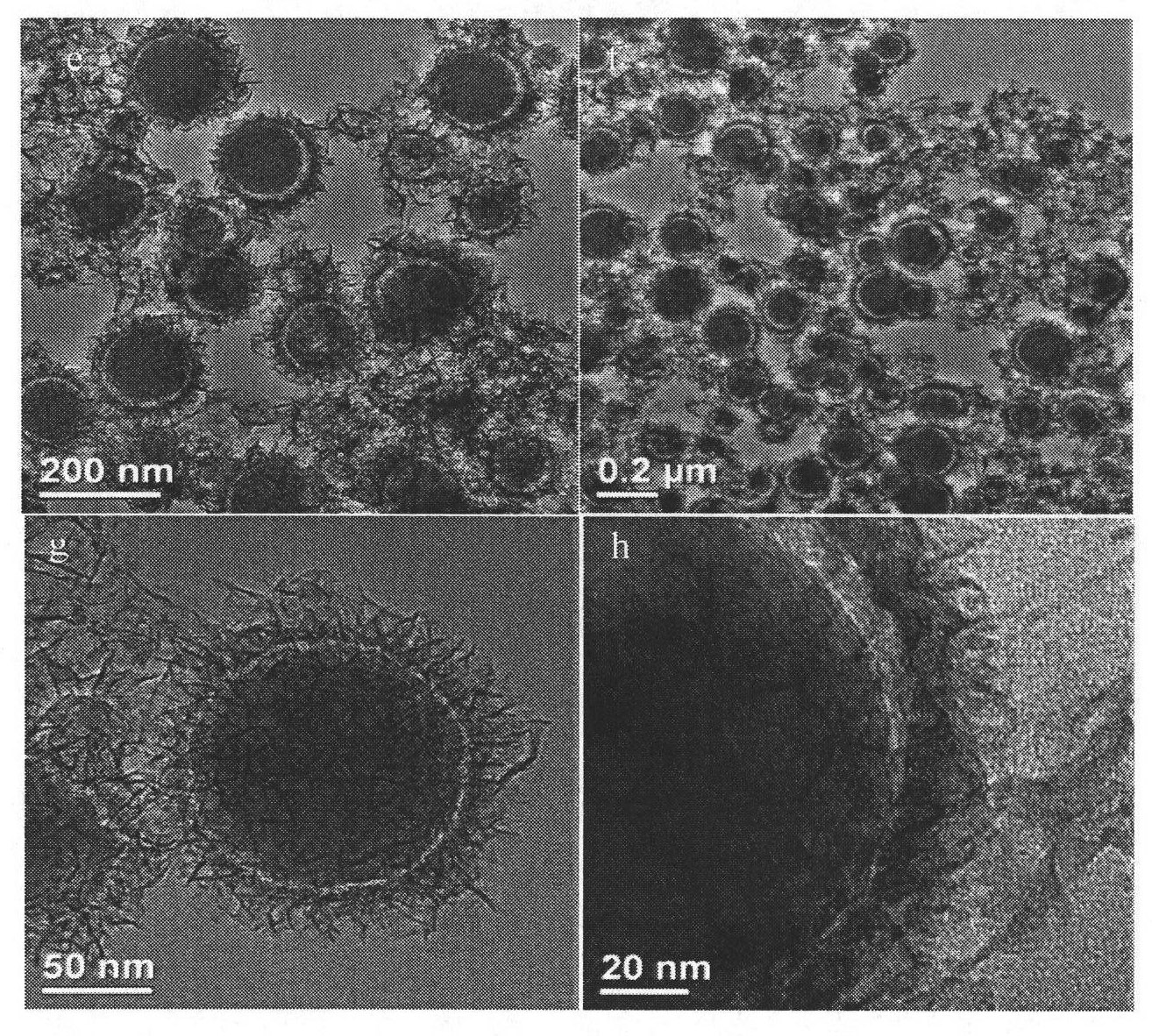

[0024] figure 1 Middle: Curve a is the XRD characterization of the magnesium silicate hollow spheres prepared in Example 2, the main diffraction peaks 2θ=19.493, 24.366, 35.307 an...

Embodiment 3

[0028] The preparation method of the present embodiment comprises the following steps:

[0029] 1. In the mixed solution of ethanol and polyethylene glycol, add 0.2 mol / L zinc nitrate solution and 0.2 mol / L sodium silicate solution successively to form a mixed solution, in which ethanol, polyethylene glycol, The volume fractions of zinc nitrate solution and sodium silicate solution are 25 parts, 2 parts, 1 part and 1 part respectively;

[0030] 2. Add 4mol / L NaOH solution to the mixed solution prepared in step 1, the ratio of NaOH solution to nitrate solution in step 1 is 1:0.15 by volume, and after magnetic stirring for 30min, transfer to the hydrothermal kettle, and at 120 React under hydrothermal conditions for 24h, filter and dry to obtain zinc silicate hollow spheres.

[0031] Figure 5 In the middle: a-b are the TEM and SEM characterizations of the zinc silicate product prepared in Example 3. It can be seen from the figure that the product has a hollow sphere structure...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com