Method for preparing indium vanadate nano particles

A technology of nano-particles and indium vanadate, which is applied in nanotechnology, chemical instruments and methods, vanadium compounds, etc., can solve the problems of less active sites on the catalyst surface, low photocatalytic activity, and small specific surface area, so as to reduce the calcination temperature, Increased specific surface area, unique process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

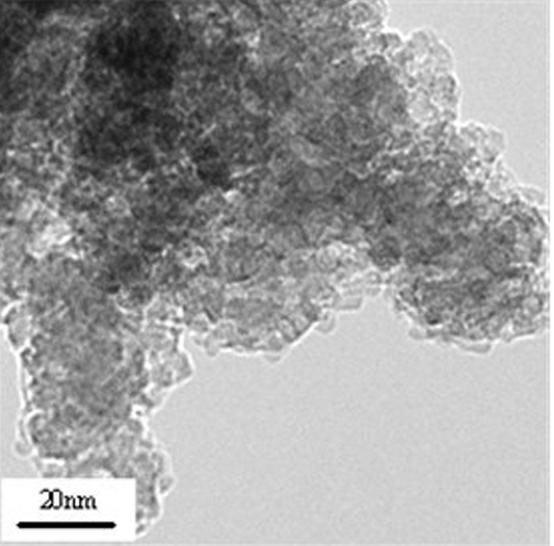

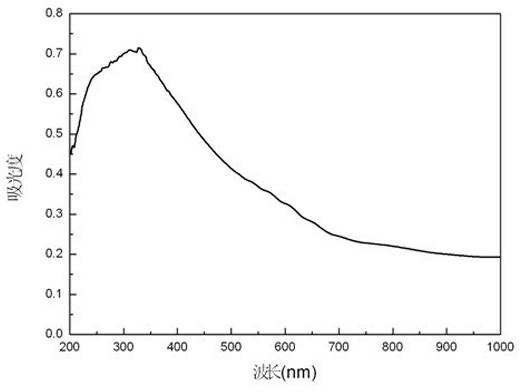

Embodiment 1

[0018] Prepare indium nitrate, ammonium metavanadate and hexadecyltrimethylammonium bromide into solutions with concentrations of 0.5mol / L, 1.0mol / L and 0.01mol / L respectively. 1:1 mixing: then add hexadecyltrimethylammonium bromide according to the ratio of indium: vanadium: cetyltrimethylammonium bromide molar ratio of 1:1:0.02, and continue to stir for 10h; use 5mol / L of potassium hydroxide solution to adjust the pH value to 8, continue to stir for 0.5h to obtain indium vanadate sol; filter the indium vanadate sol and wash it with distilled water for 3 times, and dry at 60°C for 12h to obtain a solid powder; mix 1g of the solid powder with 25g 10mol / L potassium hydroxide solution was mixed, placed in a closed reaction kettle, and hydrothermally treated at 150oC for 24h to obtain an indium vanadate precursor (hydrothermal treatment refers to the use of high-temperature and high-pressure aqueous solution to make those insoluble or difficult to Dissolve the dissolved substanc...

Embodiment 2

[0020] Prepare indium nitrate, ammonium metavanadate and cetyltrimethylammonium bromide into solutions with concentrations of 0.8 mol / L, 1.5 mol / L and 0.03 mol / L respectively. 1:1.5 mixing: then add hexadecyltrimethylammonium bromide according to the molar ratio of indium:vanadium:cetyltrimethylammonium bromide is 1:1.5:0.03, and continue to stir for 11h; use 6mol / L of potassium hydroxide solution to adjust the pH value to 8, continue stirring for 0.8h to obtain indium vanadate sol; filter the indium vanadate sol and wash it with distilled water 4 times, and dry it at 80°C for 8h to obtain a solid powder; mix 1g of the solid powder with 35g 11mol / L potassium hydroxide solution was mixed, placed in a closed reaction kettle, and subjected to hydrothermal treatment at 160oC for 12 hours to obtain an indium vanadate precursor (hydrothermal treatment refers to the use of high-temperature and high-pressure aqueous solution to make those insoluble or difficult to Dissolve the dissol...

Embodiment 3

[0022] Prepare indium nitrate, ammonium metavanadate and hexadecyltrimethylammonium bromide into solutions with concentrations of 1.0mol / L, 2.0mol / L and 0.05mol / L respectively. Under stirring conditions, the molar ratio of indium:vanadium 1:2 mixing: then add hexadecyltrimethylammonium bromide according to the ratio of indium: vanadium: cetyltrimethylammonium bromide molar ratio of 1:2:0.05, and continue to stir for 12h; use 7mol / L of potassium hydroxide solution to adjust the pH value to 8, continue to stir for 1 h to obtain indium vanadate sol; filter the indium vanadate sol and wash it with distilled water for 5 times, and dry it at 100°C for 4 hours to obtain a solid powder; mix 1 g of the solid powder with 50 g of 12 mol / L potassium hydroxide solution mixed, placed in a closed reaction kettle, hydrothermally treated at 180oC for 8h to obtain indium vanadate precursor (hydrothermal treatment refers to the use of high temperature and high pressure aqueous solution to make ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com