Electronic-grade dental gas purification process

An electronic grade, laughing gas technology, applied in the direction of nitric oxide, nitrogen oxides/oxyacids, etc., can solve problems that affect the quality of electronic products and production stability, high costs, and affect the development of the electronics industry, etc., to achieve safety Improved coefficient of performance, ease of operation, and strong operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Use low-purity laughing gas, its impurity content is: N 2 : 1000~2000PPM; H 2 O: 300~3000PPM; CO 2 : 50~500PPM.

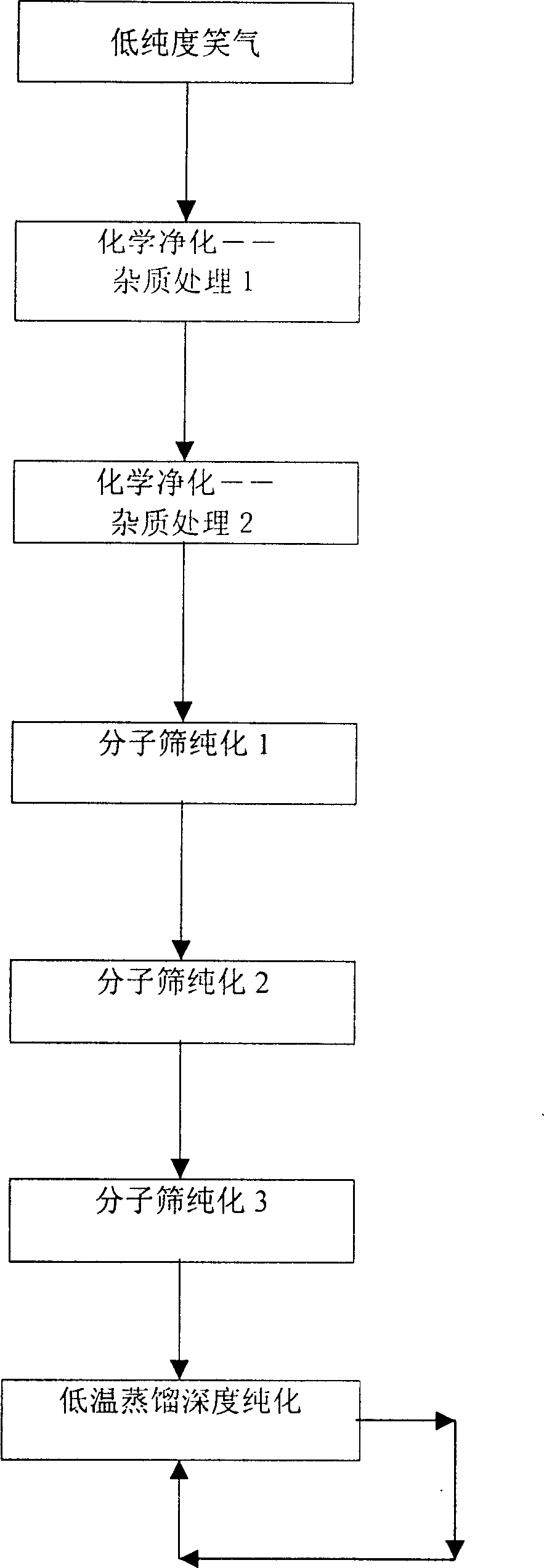

[0014] Press the above-mentioned low-purity laughing gas figure 1 The process handles:

[0015] 1. Chemical purification - impurity treatment 1

[0016] Container shape: outer diameter 229MM, height 1100MM,

[0017] Chemicals: 30% NaOH,

[0018] 2. Chemical purification - impurity treatment 2

[0019] Container shape: outer diameter 229MM, height 1100MM,

[0020] Chemicals: solid NaOH alkali tablets

[0021] 3. Molecular sieve purification 1

[0022] Container shape: outer diameter 2109MM, height 1500MM,

[0023] The outside is heated with 4000KW resistance wire

[0024] Chemicals: 1 kg fine-pore silica gel at each end, coconut shell activated carbon in the middle

[0025] Remarks: When working, work at normal temperature, the pressure is controlled at 0.3 ~ 1MPA. During regeneration, the temperature is controlled at 250 degrees Celsius, dry nitr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com