Mild thick-flavor white spirit and production method thereof

A sauce-flavored liquor and a production method technology, applied in the field of brewing, can solve the problems of low yield, heavy bad taste, heavy sour taste, etc., and achieve the effects of increased yield, long tail and strong sauce aroma

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

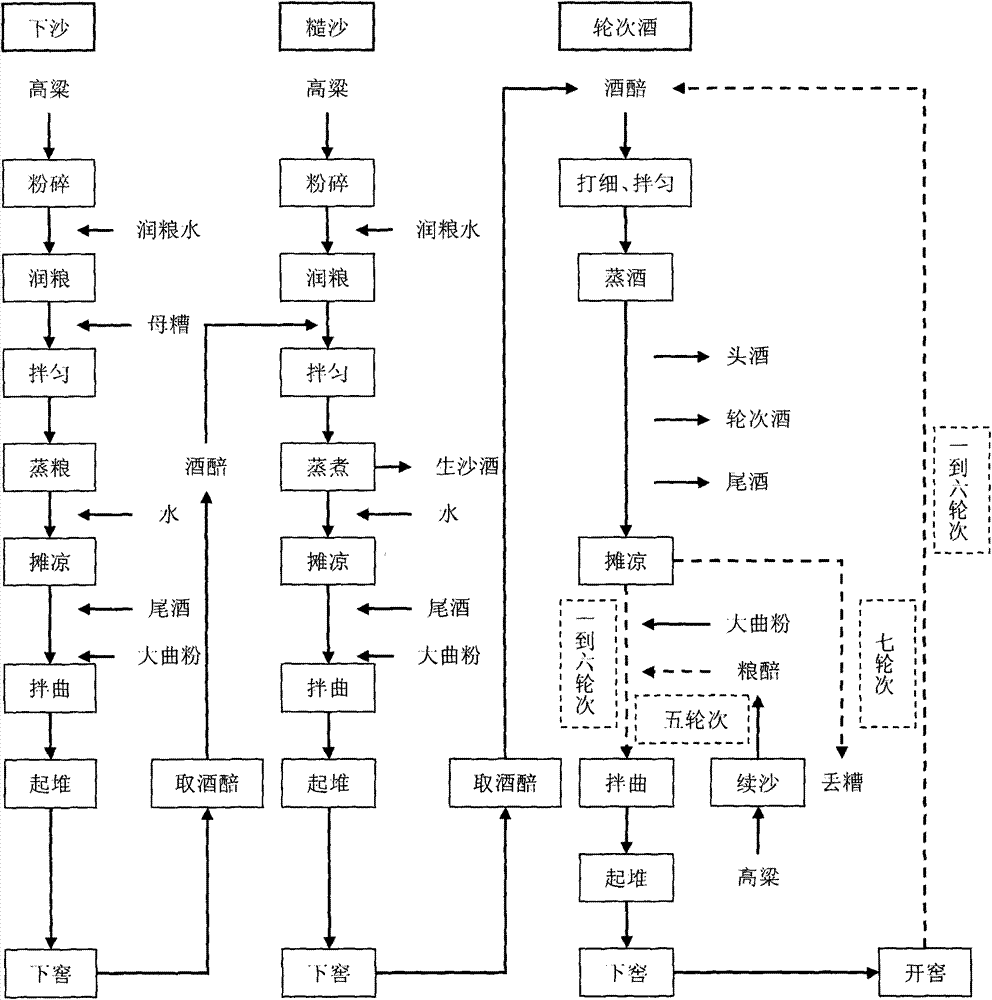

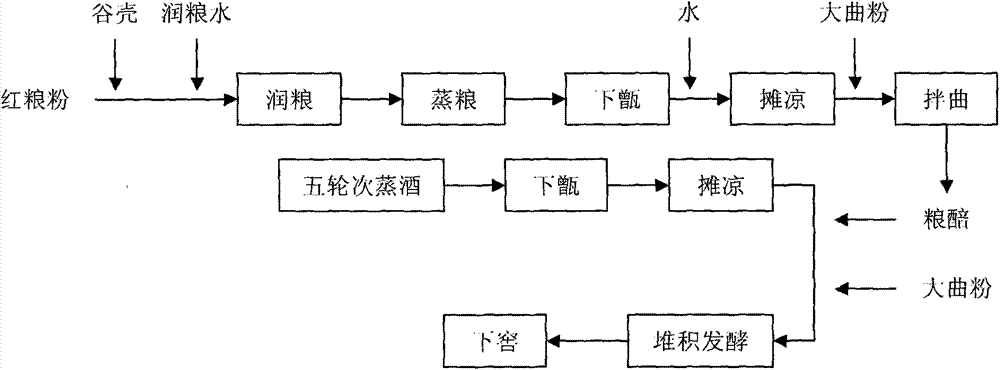

Method used

Image

Examples

example 1

[0033] Make it as follows:

[0034] (1) Xiasha: Use Xiaonuo red sorghum produced in the hilly area of northwest Guizhou Province as raw material, crush the sorghum into a ratio of whole grain to broken grain of 7:3, add 52% of the mass of sorghum with hot water above 95°C for moistening Grain, mixed evenly, piled up to moisten the grain for 12 hours; the high-quality wine grains that were not steamed after the last round of fermentation in the previous year were used as the mother's grains, and the mother's grains with 10% of the quality of the sand sorghum were weighed out, and finely crushed with a shattering machine. Add it to the sorghum after moistening the grain, put it on the steamer to steam the grain; start to steam the grain for 120 minutes with the oxtail running water, and the steamed grain will be about half-cooked and then it will be out of the steamer; after the grain is out of the steamer, sprinkle 2% of the mass of the sorghum in the sand at 95 °C water, and...

example 3

[0039] Make it as follows:

[0040] (1) Xiasha: Use Xiaonuo red sorghum produced in the hilly area of northwest Guizhou Province as raw material, crush the sorghum into a ratio of whole grain to broken grain of 7:3, add 50% of the mass of sorghum with hot water above 95°C for moistening Grain, mix evenly; when the accumulation temperature reaches 48°C, the high-quality wine grains that have not been steamed after the last round of fermentation in the previous year are used as the mother's grains, and the mother's grains with 10% of the mass of sand sorghum are weighed out, and finely crushed with a whisk , add it to the sorghum after moistening the grain, put it on the retort to steam the grain; start to steam the grain for 120 minutes with the oxtail running water, and the steamed grain will be about half-cooked and then it will be out of the retort; after the grain unstrained spirits are out of the retort, sprinkle 95°C of 2% of the mass of the sorghum in the sand After th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com