Multiple step type drilling and protecting integrated system and process for soft coal seam

A soft coal seam, step-by-step technology, applied in the field of soft coal seam step-by-step drilling and maintenance integration system and technology, can solve the problems of local collapse, hole collapse, failure to feed the hole protection pipe into the borehole, etc., and achieve the goal of supporting the hole wall, large diameter effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

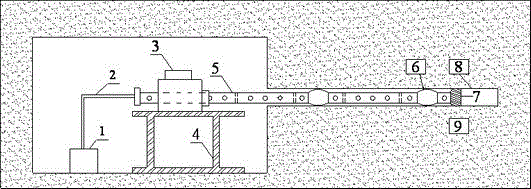

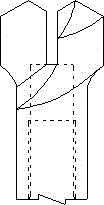

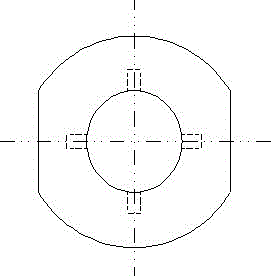

[0029] Embodiment 1. The step-by-step integrated drilling and protection system for soft coal seams includes: air compressor 1, high-pressure rubber hose 2, hole protection drill 3, frame 4, hole protection drill pipe 5, guide 6 and simple drill bit 7, hole protection The drilling machine 3 is located on the frame 4, the hole-protecting drill rod 5 passes through the hole-protecting drill 3, the tail of the hole-protecting drill rod 5 is connected with the air compressor 1 through the high-pressure rubber hose 2, and a simple drill bit is installed on the top of the first section of the hole-protecting drill rod 5 7. A guide 6 is installed in the middle of the hole protection drill pipe 5, and the guide 6 is located in the gas drainage borehole 8 in the soft coal seam.

[0030] The outer diameter of the hole-protecting drill rod is 5 mm to 20 mm smaller than the diameter of the simple drill bit 7. The hole-protecting drill rod is a hollow rod, and the wall of the hole-protectin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com