Preparation method of diatomite heavy-metal adsorption material

An adsorption material, diatomite technology, applied in chemical instruments and methods, adsorption water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problem of poor dispersion of aluminum magnesium hydroxide metal oxides and insufficient contact of heavy metal ions , affect the adsorption effect and other issues, to achieve the effect of convenient operation, effective removal, and easy large-scale industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

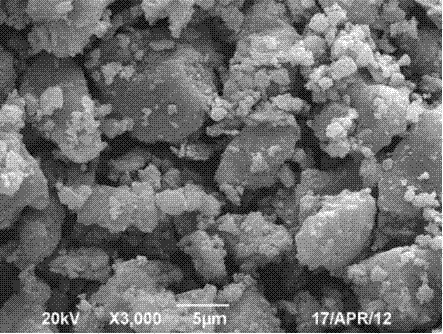

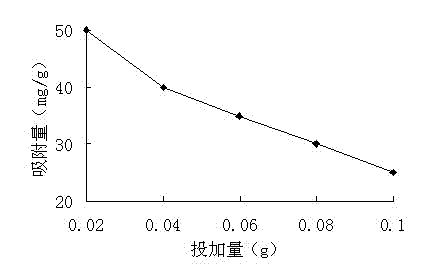

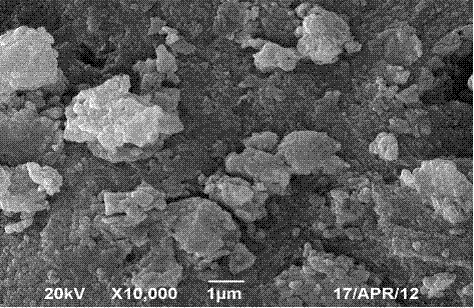

Embodiment 1

[0030] Prepare aluminum chloride solution with a mass concentration of 325g / L and magnesium chloride solution with a mass concentration of 50g / L respectively, mix equal volumes to form a mixed solution A, and heat solution A to 60oC; the molar ratio of sodium carbonate and sodium hydroxide is 1:1 Mix and make solution B of 95g / L, heat solution B to 70oC; add diatomaceous earth in the amount of 10g / L to the heated solution A, under the condition of stirring speed of 250r / min Mix for 10 minutes; then add an equal volume of solution B that has been heated up, and react for 15 minutes under the condition of stirring speed of 350r / min; perform suction filtration after standing still for 20 minutes, and repeatedly rinse the filter cake with deionized water until the filtrate no longer contains aluminum ions and carbonate ions; then dried at 105oC for 120min, and naturally cooled to room temperature to obtain diatomaceous earth-loaded aluminum magnesium oxyhydroxide heavy metal adsorp...

Embodiment 2

[0033] Prepare the aluminum chloride solution with a mass concentration of 325g / L and the magnesium chloride solution with a mass concentration of 50g / L respectively, mix equal volumes to form a mixed solution A, and heat the solution A to 80oC; the molar ratio of sodium carbonate and sodium hydroxide is 1:1 Mix and make solution B of 95g / L, heat solution B to 80oC; add diatomaceous earth in the amount of 10g / L to the heated solution A, under the condition of stirring speed of 250r / min Mix for 10 minutes; then add an equal volume of solution B that has been heated up, and react for 25 minutes at a stirring speed of 350r / min; perform suction filtration after standing still for 20 minutes, and repeatedly rinse the filter cake with deionized water until the filtrate no longer contains aluminum ions and carbonate ions; then dried at 105oC for 120min, and naturally cooled to room temperature to obtain diatomaceous earth-loaded aluminum magnesium oxyhydroxide heavy metal adsorption m...

Embodiment 3

[0036]Prepare the aluminum chloride solution with a mass concentration of 325g / L and the magnesium chloride solution with a mass concentration of 50g / L respectively, mix equal volumes to form a mixed solution A, and heat the solution A to 80oC; the molar ratio of sodium carbonate and sodium hydroxide is 1:1 Mix and make solution B of 95g / L, heat solution B to 80oC; add diatomaceous earth in the amount of 10g / L to the heated solution A, under the condition of stirring speed of 250r / min Mix for 10 minutes; then add an equal volume of solution B that has been heated up, and react for 25 minutes at a stirring speed of 350r / min; perform suction filtration after standing still for 20 minutes, and repeatedly rinse the filter cake with deionized water until the filtrate no longer contains aluminum ions and carbonate ions; then dried at 105oC for 120min, and naturally cooled to room temperature to obtain diatomaceous earth-loaded aluminum magnesium oxyhydroxide heavy metal adsorption ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com