Cross-link polyamino acid type metal adsorbent, method for preparing same and method for adsorbing metal

A polyamino acid, amino acid type technology, applied in chemical instruments and methods, adsorption water/sewage treatment, water/sludge/sewage treatment, etc., to achieve good environmental protection effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

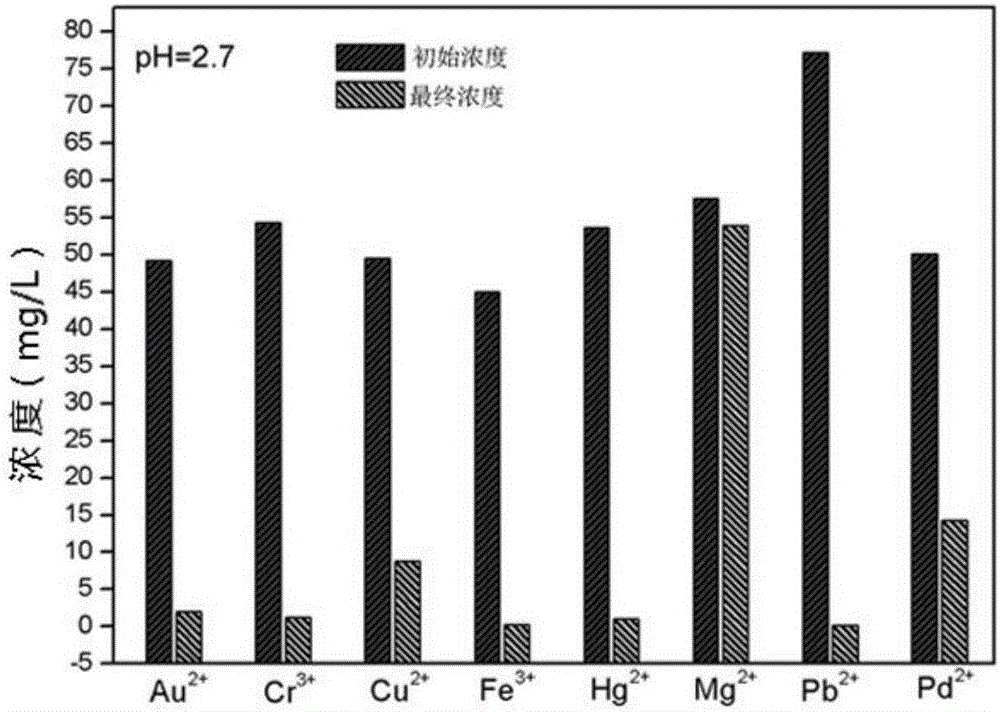

Examples

preparation example Construction

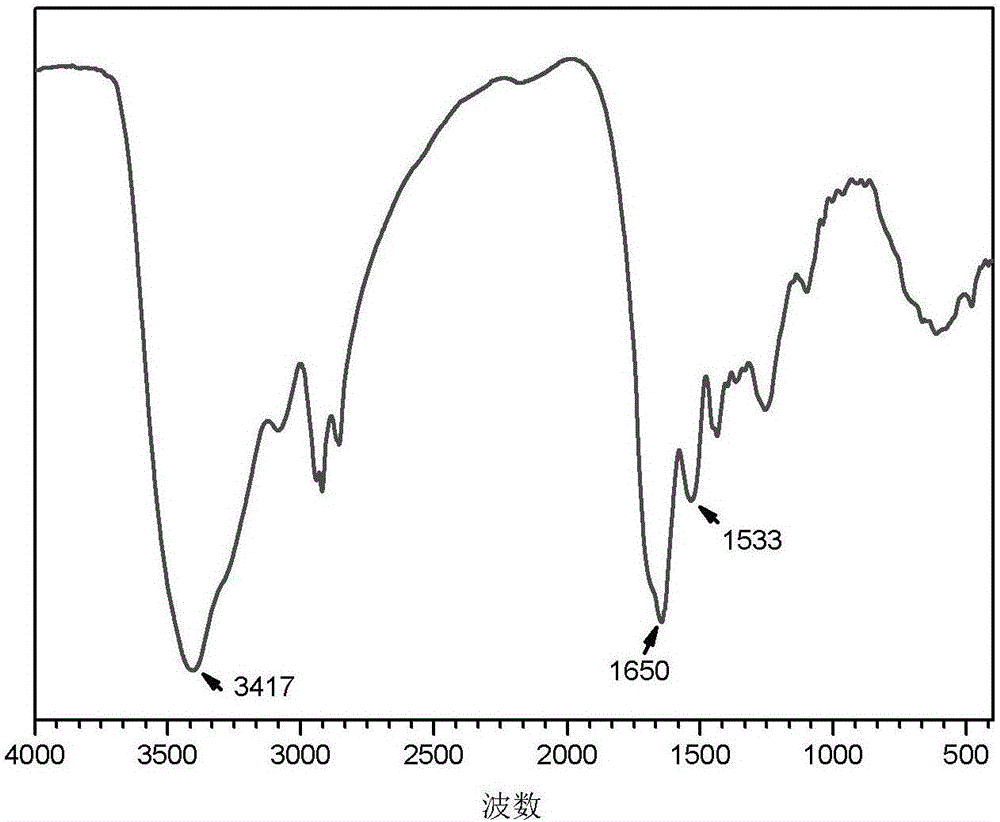

[0052] The present invention also provides a method for preparing a cross-linked polyamino acid metal adsorbent, comprising the following steps:

[0053] Perform polycondensation reaction of one or more amino acids with a cross-linking agent with a functionality ≥ 2 to obtain a cross-linked polyamino acid;

[0054] Or carry out a cross-linking reaction between a straight-chain polyamino acid and a cross-linking agent with a functionality ≥ 2 to obtain a cross-linked polyamino acid;

[0055] Or carry out a crosslinking reaction between branched polyamino acid and a crosslinking agent with a functionality ≥ 2 to obtain crosslinked polyamino acid;

[0056] Or carry out a crosslinking reaction with a mixture of linear polyamino acid and branched polyamino acid and a crosslinking agent with a functionality ≥ 2 to obtain a crosslinked polyamino acid.

[0057] In the present invention, the content of the cross-linking agent with functionality ≥ 2 is X, where 0%

Embodiment 1

[0081] To prepare hyperbranched polylysine, add 100 grams of lysine to a 500-milliliter round-bottomed flask equipped with a Dean-Stock trap, heat to 180° C. and stir for 12 hours, then vacuumize for 10 hours. The reaction system was cooled to room temperature to obtain 89 grams of hyperbranched polylysine.

Embodiment 2

[0083] For the preparation of polyglutamic acid, add 59g of ground L-glutamic acid and 52mL of benzyl alcohol into a 500mL three-necked bottle, after mechanically stirring evenly, slowly add 48mL of 60% concentrated sulfuric acid dropwise with a constant pressure dropping funnel, The temperature of the oil bath was controlled at 70°C until the reaction solution became clear. Heating was stopped, and after the reaction solution dropped to normal temperature, it was added to 65 g of sodium bicarbonate in ice water. After filtration, the crude product was recrystallized with distilled water at 70°C to obtain flaky crystals, washed with ethanol and ether in sequence, and dried in vacuum to obtain the white product γ-benzyl-L-glutamic acid.

[0084] Add 10g of γ-benzyl-L-glutamic acid into 100mL of anhydrous tetrahydrofuran, add 5g of triphosgene while stirring, and react in an oil bath at 50-60°C for 3 hours. Hydrogen chloride gas. After the solution was clarified, the heating w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com