Hydrophobic honeycomb-shaped zeolite material as well as preparation method and application thereof

A zeolite material and honeycomb technology, which is applied in the field of hydrophobic honeycomb zeolite materials and its preparation, can solve the problems of single pore size, large influence of zeolite specific surface area, and complicated hydrophobic treatment steps, so as to improve hydrophobic performance and competitive adsorption capacity , The effect of broadening the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

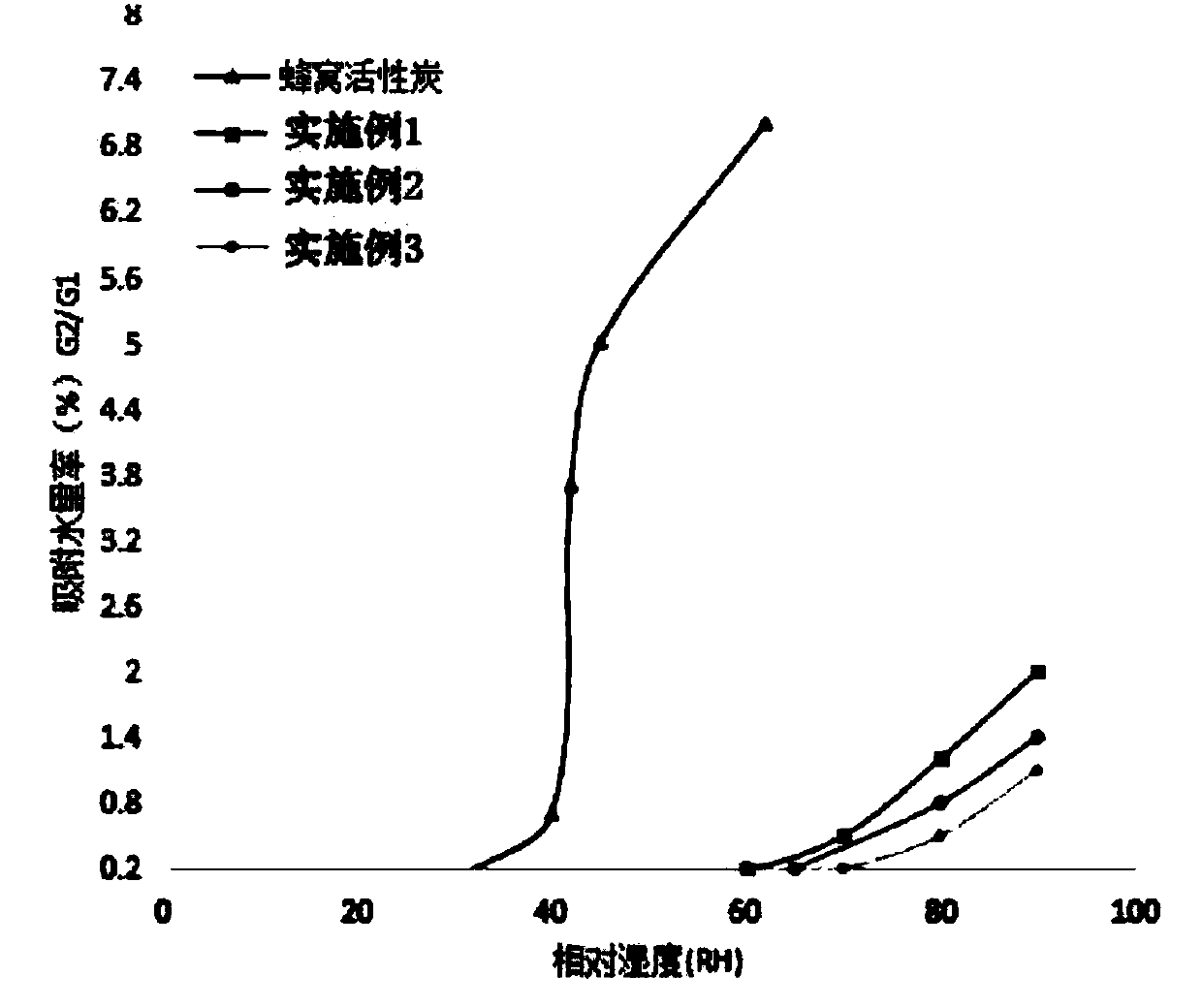

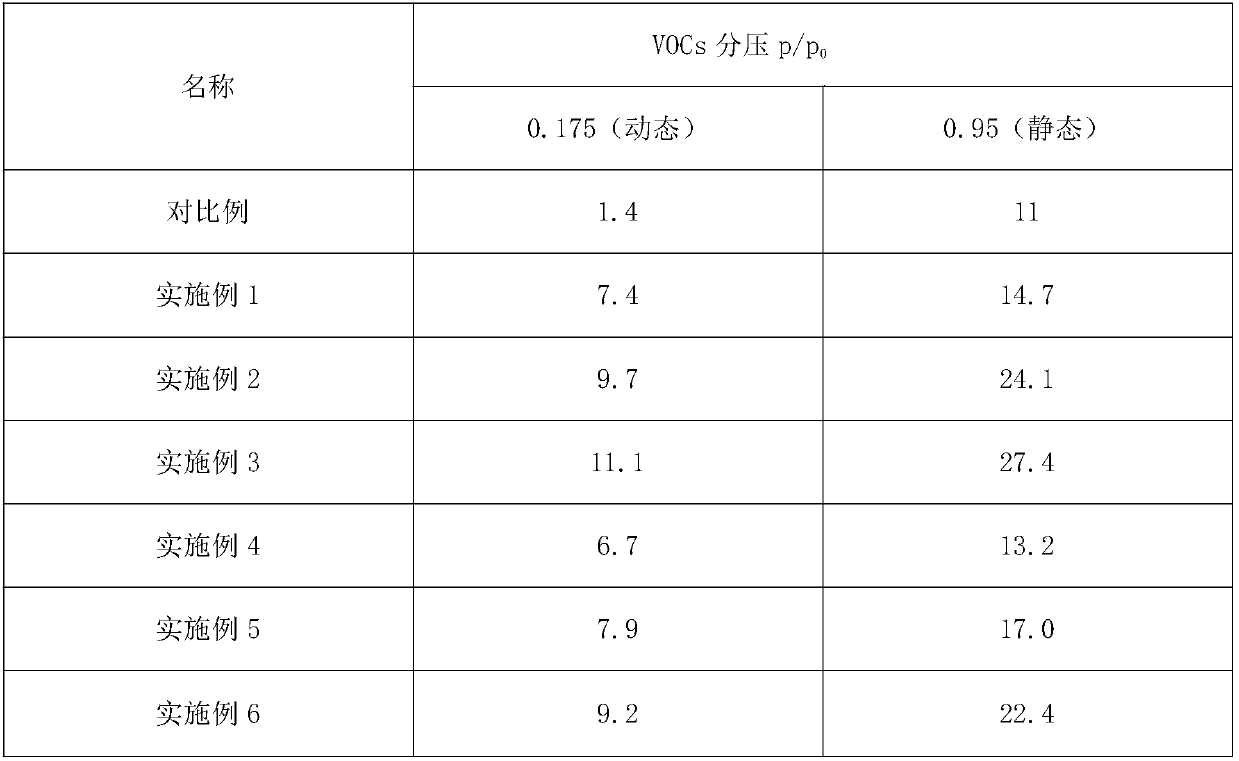

Examples

Embodiment 1

[0040] A preparation method of hydrophobic honeycomb zeolite (molecular sieve) material, comprises the following steps (carrier-free molding):

[0041] Raw material selection and proportioning: Weigh two parts of ZSM-5 molecular sieve powder, the crystallinity is above 70%, the molar ratio of silicon to aluminum is greater than 100, and the specific surface area is greater than 300m 2 / g; Weigh three parts of Y-type molecular sieve powder, whose crystallinity is above 70%, the molar ratio of silicon to aluminum is greater than 7, and the specific surface area is greater than 300m 2 / g; mix the two material powders evenly to obtain a mixed powder.

[0042] Honeycomb molding steps: based on the weight of the proportion, mix 41 parts of powder, 5 parts of CMC, 40 parts of silica sol, and about 14 parts of water, fully mix into mud, smelt into segments, pass through a honeycomb structure steel mold of a certain size, It is formed into a honeycomb blank by extrusion molding method...

Embodiment 2

[0045] A preparation method of hydrophobic honeycomb zeolite (molecular sieve) material, comprises the following steps (carrier-free molding):

[0046] Raw material selection and proportioning: Weigh three parts of ZSM-5 molecular sieve material, whose crystallinity is above 70%, the molar ratio of silicon to aluminum is greater than 100, and the specific surface area is greater than 300m 2 / g; Weigh two parts of Y-type molecular sieve materials, the crystallinity of which is above 70%, the molar ratio of silicon to aluminum is greater than 7, and the specific surface area is greater than 300m 2 / g; Mix the two materials evenly to obtain a mixed powder.

[0047] Honeycomb forming steps: based on the weight of the share, mix 47 parts of powder, 6 parts of MC, 42 parts of aluminum sol, and about 5 parts of water, fully mix into mud, smelt into segments, pass through a honeycomb structure steel mold of a certain size, It is formed into a honeycomb blank by extrusion molding meth...

Embodiment 3

[0050] A preparation method of hydrophobic honeycomb zeolite (molecular sieve) material, comprises the following steps (carrier-free molding):

[0051] Selection and proportioning of raw materials: Weigh a portion of ZSM-5 molecular sieve powder, whose crystallinity is above 70%, the molar ratio of silicon to aluminum is greater than 100, and the specific surface area is greater than 300m 2 / g; Weigh a portion of Y-type molecular sieve powder, whose crystallinity is above 70%, the molar ratio of silicon to aluminum is greater than 7, and the specific surface area is greater than 300m 2 / g; Mix the two materials evenly to obtain a mixed powder.

[0052] Honeycomb forming steps: based on the weight of the share, mix 50 parts of powder, 4 parts of animal glue, 44 parts of zirconium sol, and about 2 parts of water, fully mix into mud, smelt into segments, pass through a honeycomb structure steel mold of a certain size, It is formed into a honeycomb blank by extrusion molding meth...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Pore diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com