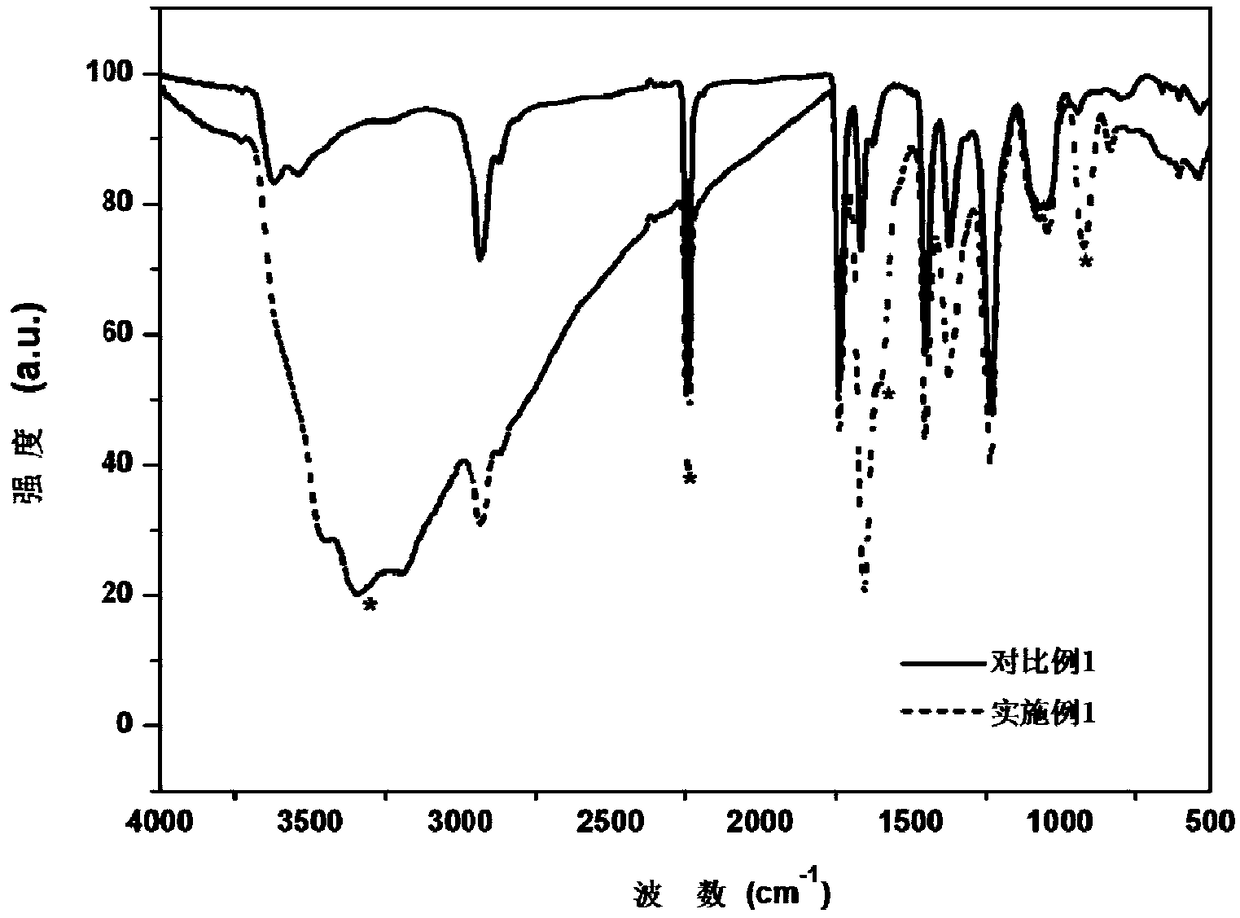

Amidoximized polyacrylonitrile fiber and preparation method and applications thereof

A technology of polyacrylonitrile fiber and polyacrylonitrile, which is applied in chemical instruments and methods, fiber chemical characteristics, inorganic chemistry, etc. It can solve the problems of brittle fracture or powderization, loss of fiber characteristics, and influence on fiber preparation, etc., and achieves simple operation , excellent adsorption performance, and the effect of saving preparation cost and time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] A preparation method of amidoximated polyacrylonitrile fiber, comprising:

[0040]Get polyacrylonitrile (molecular weight is 10 * 10 4 ) was dissolved in N,N-dimethylformamide (DMF), and stirred at room temperature for 10 h to obtain a transparent polyacrylonitrile solution. Dissolve hydroxylamine hydrochloride in N,N-dimethylformamide (DMF), ultrasonically oscillate for 5 minutes, and stir at room temperature for 1 hour, so that hydroxylamine hydrochloride is fully dissolved in DMF to obtain a hydroxylamine hydrochloride solution, wherein the concentration of hydroxylamine hydrochloride is 10g / L.

[0041] The polyacrylonitrile solution and the hydroxylamine hydrochloride solution were mixed, stirred at room temperature for 5 minutes, so that the two solutions were fully mixed, and the bubbles in the solution were removed by ultrasonic vibration to obtain a spinning solution, wherein the mass concentration of polyacrylonitrile was 10%. The molar ratio of polyacryloni...

Embodiment 2

[0044] A preparation method of amidoximated polyacrylonitrile fiber, comprising:

[0045] Get polyacrylonitrile (molecular weight is 8 * 10 4 ) was dissolved in dimethyl sulfoxide (DMSO), and stirred at room temperature for 5 h to obtain a transparent polyacrylonitrile solution. Hydroxylamine hydrochloride was dissolved in dimethyl sulfoxide (DMSO), ultrasonically oscillated for 10 minutes, and then stirred at room temperature for 2 hours, so that hydroxylamine hydrochloride was fully dissolved in DMSO to obtain a hydroxylamine hydrochloride solution, wherein the concentration of hydroxylamine hydrochloride was 30 g / L.

[0046] The polyacrylonitrile solution and the hydroxylamine hydrochloride solution were mixed, stirred at room temperature for 10 minutes, so that the two solutions were fully mixed, and the bubbles in the solution were removed by ultrasonic vibration to obtain a spinning solution, wherein the mass concentration of polyacrylonitrile was 8%. The molar ratio of...

Embodiment 3

[0049] Get polyacrylonitrile (molecular weight is 15 * 10 4 ) was dissolved in N,N-dimethylacetamide, stirred at room temperature for 3 h to obtain a transparent polyacrylonitrile solution. Dissolve hydroxylamine hydrochloride in N,N-dimethylacetamide, ultrasonically oscillate for 5 minutes, and stir at room temperature for 1 hour, so that hydroxylamine hydrochloride is fully dissolved in N,N-dimethylacetamide to obtain a hydroxylamine hydrochloride solution, in which the hydrochloric acid The concentration of hydroxylamine is 20g / L.

[0050] The polyacrylonitrile solution and the hydroxylamine hydrochloride solution were mixed, stirred at room temperature for 15 minutes, so that the two solutions were fully mixed, and the bubbles in the solution were removed by ultrasonic vibration to obtain a spinning solution, wherein the mass concentration of polyacrylonitrile was 15%. The molar ratio of polyacrylonitrile to hydroxylamine hydrochloride is 1:1.25.

[0051] Put the spinnin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Linear density | aaaaa | aaaaa |

| Breaking strength | aaaaa | aaaaa |

| Linear density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com