Porous heavy metal ion adsorbent based on biochar and preparation method of porous heavy metal ion adsorbent

A technology of biomass carbon and heavy metals, applied in the field of porous materials, can solve the problems of difficult separation and difficult recovery, and achieve the effects of industrialized production, easy operation of the production process, and easy availability of raw materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

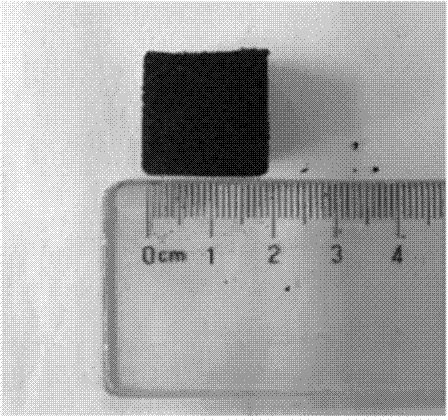

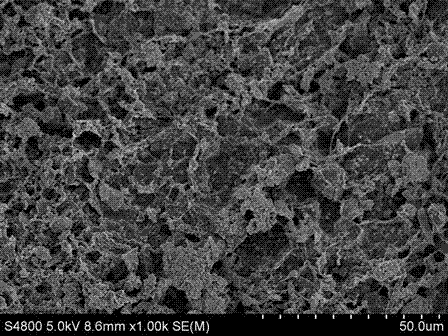

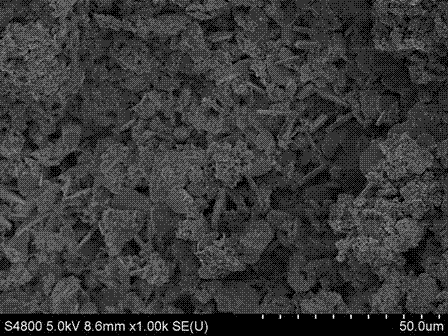

[0028] Preparation of a porous heavy metal adsorbent based on biochar:

[0029] (1) Mix 35 g of biochar with 10 g of kaolin and 5 g of hydroxyapatite powder.

[0030] (2) Add 9 g of acrylamide and an appropriate amount of N,N'-methylenebisacrylamide to 50 mL of water.

[0031] (3) Mix the powder obtained in step 1 with the gel liquid obtained in step 2, and put it into a planetary ball mill to grind and make slurry to obtain a slurry with a solid content of 50 wt%.

[0032] (4) Take out the slurry obtained in step 3, add a certain amount of surfactant sodium lauryl sulfate, and then stir vigorously with a mechanical stirrer until the volume of the slurry expands to twice the original state.

[0033] (5) Under continuous stirring conditions, add an appropriate amount of N,N,N',N'-tetramethylethylenediamine dropwise to the slurry with a dropper, and then add 10 mL of 10 wt% sodium sulfate.

[0034] (6) Quickly inject the slurry obtained in step 5 into a mold of 1.7*1.7*1.7cm ...

Embodiment 2

[0037] In this example, a porous adsorbent based on biochar is used to adsorb and remove heavy metal lead, and the steps are as follows:

[0038] Put 0.2 g of the porous adsorbent obtained in Example 1 into 500 mL of 50 mg / L lead solution for adsorption at room temperature; take a sampling point at regular intervals and monitor for 24 hours; the collected samples are measured by ICP-OES, and the material The unit adsorption capacity of the material, and with time as the abscissa, the lead adsorption kinetic curve of the material is made; the data calculated by fitting are as follows:

[0039] The lead adsorption performance of table 1 example 1 gained porous adsorbents.

[0040]

Embodiment 3

[0042] In this example, a porous adsorbent based on biochar is used to adsorb and remove heavy metal lead, and the steps are as follows:

[0043] Put 0.1 g of the porous adsorbent obtained in Example 1 into 250 mL of 50-250 mg / L lead solution for adsorption at room temperature; each concentration is sampled at 24 hours; the collected samples are measured by ICP-OES, and the unit adsorption capacity of the material is calculated , and taking the equilibrium concentration as the abscissa, the lead adsorption thermodynamic curve of the material is made; the data calculated by fitting are as follows:

[0044] The lead adsorption performance of table two example 1 gained porous adsorbent

[0045]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com