Magnetic biochar and preparation method thereof

A biochar and magnetic technology, applied in the field of biomass resource utilization, can solve the problems of poor adsorption performance of biochar, and achieve the effect of improving adsorption performance and facilitating regeneration and recycling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

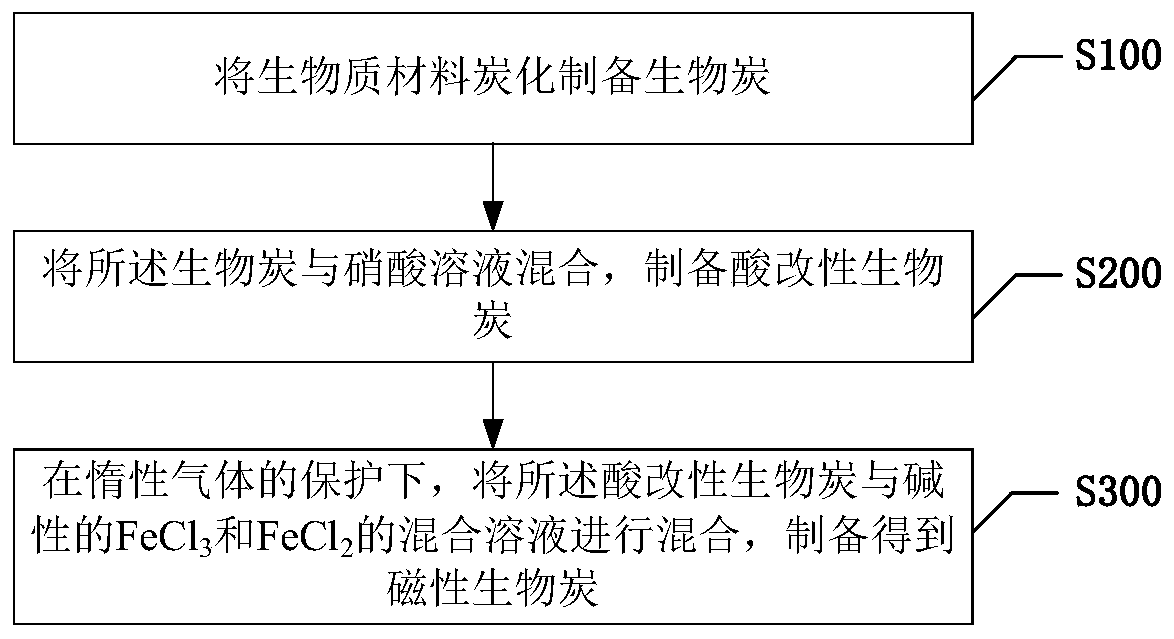

Method used

Image

Examples

Embodiment 1

[0065] 5.0g biomass material particles were weighed and placed in a hydrothermal reactor, 50ml of deionized water was added, the reactor was sealed, and the reactor was placed in an electric heating blast drying box, and the reaction temperature was set to 240°C, The reaction time is set to 24h. After the heating reaction is completed, the reaction kettle is taken out, and the product is filtered and separated. After that, the product is washed with deionized water until it is neutral, and then placed in a drying box for drying treatment to obtain biochar. .

[0066] Take 5g of biochar, mix it with 2mol / L nitric acid solution in a 250ml conical flask according to the ratio of solid-liquid ratio of 1:10, and place it in an oven, set the oven temperature to 110°C, soak for 2h, After soaking, the temperature of the drying box was lowered to room temperature, and the acid-modified biochar was taken out, washed with deionized water until the supernatant was neutral, and dried to ob...

Embodiment 2

[0069] 5.0g biomass material particles were weighed and placed in a hydrothermal reactor, 50ml of deionized water was added, the reactor was sealed, and the reactor was placed in an electric heating blast drying box, and the reaction temperature was set to 240°C, The reaction time is set to 24h. After the heating reaction is completed, the reaction kettle is taken out, and the product is filtered and separated. After that, the product is washed with deionized water until it is neutral, and then placed in a drying box for drying treatment to obtain biochar. .

[0070] Take 5g of biochar, mix it with 2mol / L nitric acid solution in a 250ml conical flask according to the ratio of solid-liquid ratio of 1:10, and place it in an oven, set the oven temperature to 110°C, soak for 2h, After soaking, the temperature of the drying box was lowered to room temperature, and the acid-modified biochar was taken out, washed with deionized water until the supernatant was neutral, and dried to ob...

Embodiment 3

[0073] 5.0g biomass material particles were weighed and placed in a hydrothermal reactor, 50ml of deionized water was added, the reactor was sealed, and the reactor was placed in an electric heating blast drying box, and the reaction temperature was set to 240°C, The reaction time is set to 24h. After the heating reaction is completed, the reaction kettle is taken out, and the product is filtered and separated. After that, the product is washed with deionized water until it is neutral, and then placed in a drying box for drying treatment to obtain biochar. .

[0074] Take 5g of biochar, mix it with 2mol / L nitric acid solution in a 250ml conical flask according to the ratio of solid-liquid ratio of 1:10, and place it in an oven, set the oven temperature to 110°C, soak for 2h, After soaking, the temperature of the drying box was lowered to room temperature, and the acid-modified biochar was taken out, washed with deionized water until the supernatant was neutral, and dried to ob...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Maximum adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com