MOFs dual-metal adsorption material (Fe, Co)-BTC and preparation method thereof

A technology of adsorption material and bimetal, which is applied in the field of adsorption materials to achieve the effect of improving adsorption capacity, good repeatability and enhancing force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

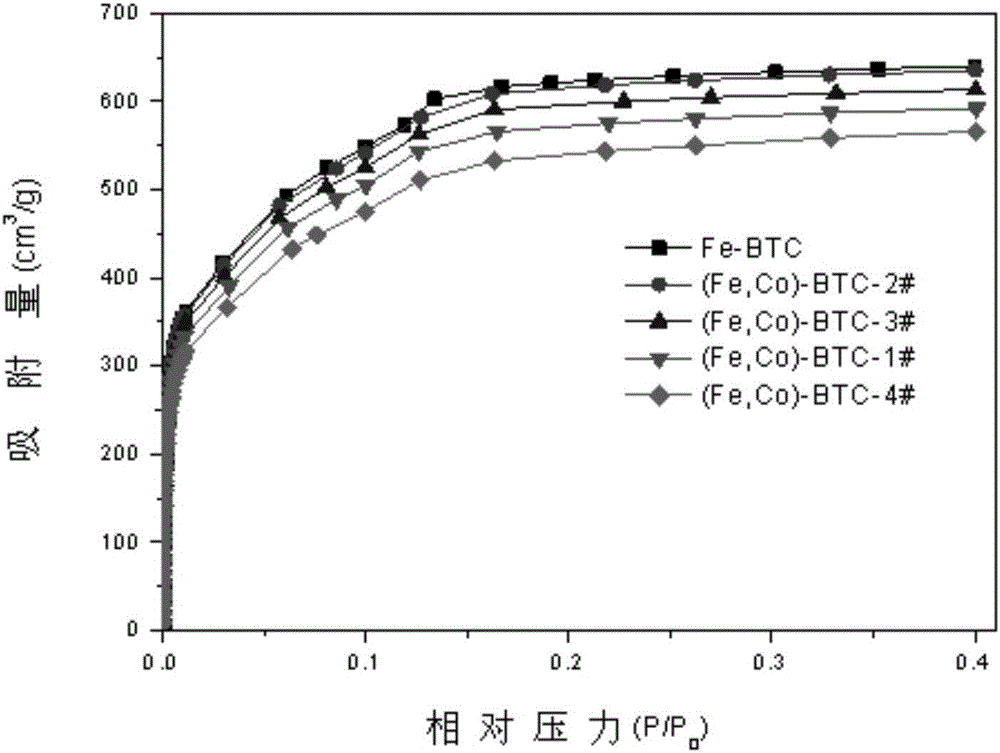

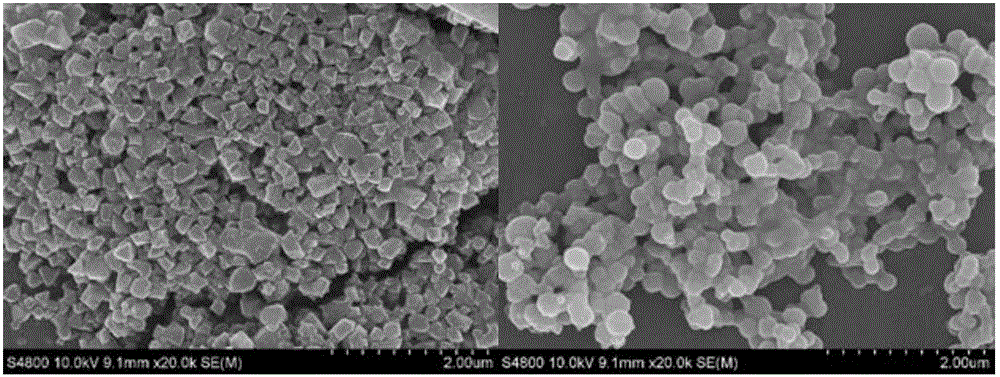

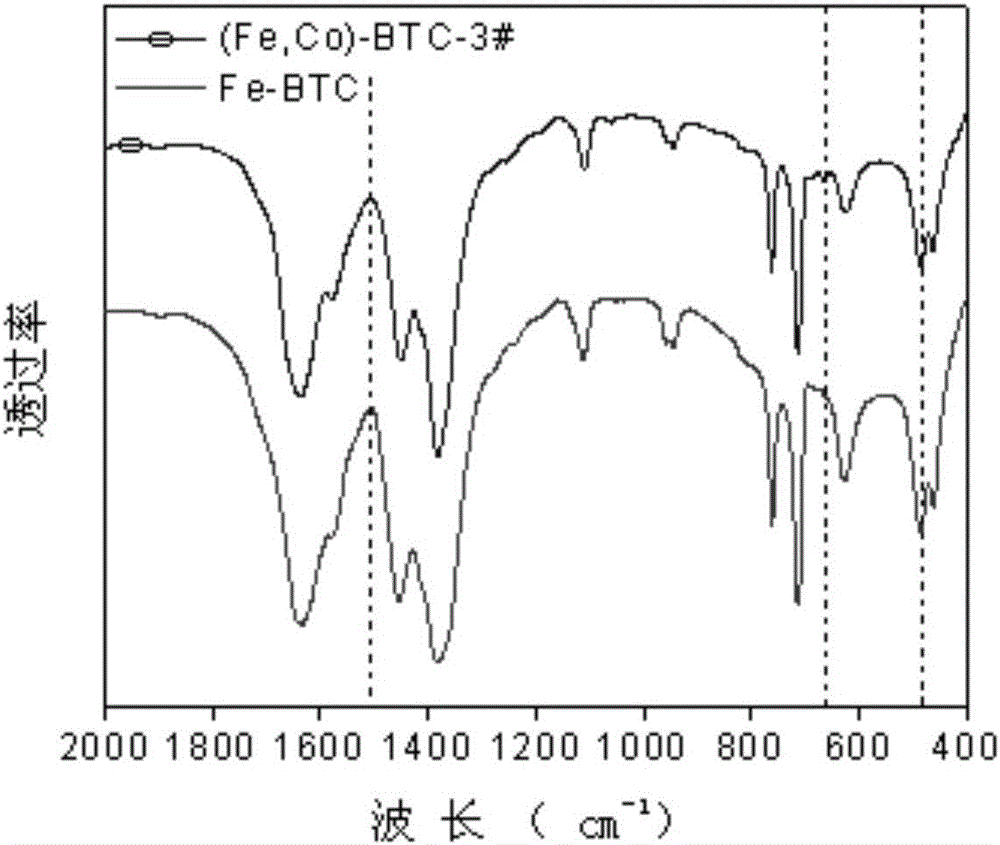

[0024] Stir and mix reduced iron powder (10mmol), hexahydrate and cobalt nitrate (0.5mmol), m-tribenzoic acid (6.7mmol) and distilled water (45ml) to obtain a ternary water mixed solution, and then add HNO 3 Solution (0.4ml) and 40% NaF solution (0.8ml) were mixed to obtain the reaction mother liquor, and then the reaction mother liquor was placed in a reaction kettle and heated to 150°C for 16 hours to obtain a mixture containing the reaction product (Fe, Co)-BTC solution, cooled to room temperature (25°C). Add 25ml of DMF to the (Fe,Co)-BTC reaction product mixture obtained from the reaction, stir at room temperature for 2h, and use G 1 Funnel filtration removed most of the unreacted ligands, followed by drying to obtain crude solid (Fe,Co)-BTC material. Then the solid material was soaked in absolute ethanol, heat-treated at 100° C. for 24 hours, repeated twice, centrifuged, and dried to obtain a solid material. Then add 0.75g of ammonium fluoride and water, heat at 60°C f...

Embodiment 2

[0026] Stir and mix reduced iron powder (10mmol), hexahydrate and cobalt nitrate (1mmol), m-tribenzoic acid (7.2mmol) and distilled water (50ml) to obtain a ternary water mixed solution, and then add HNO 3solution (0.5ml) and 40% NaF solution (0.9ml) were mixed to obtain a mother liquor, and then the mother liquor was placed in a reaction kettle and heated to 160°C for 12 hours to obtain a mixed reaction product containing (Fe, Co)-BTC solution, cooled to room temperature (25°C). Add 30ml of DMF to the (Fe,Co)-BTC reaction product mixture obtained from the reaction, stir at room temperature for 2h, and use G 1 Funnel filtration removed most of the unreacted ligands, followed by drying to obtain crude solid (Fe,Co)-BTC material. Then the solid material was soaked in absolute ethanol, heat-treated at 120° C. for 16 hours, repeated twice, centrifuged, and dried to obtain a solid material. Then add 0.8 g of ammonium fluoride and water, heat at 80° C. for 8 hours, centrifuge, soa...

Embodiment 3

[0028] Stir and mix reduced iron powder (10mmol), hexahydrate, cobalt nitrate (2mmol), mestribenzoic acid (8mmol) and distilled water (55ml) to obtain a ternary water mixed solution, and then add HNO 3 solution (0.5ml) and 40% NaF solution (1ml) were mixed to obtain the reaction mother liquor, and then the reaction mother liquor was placed in a reaction kettle and heated to 180°C for 8 hours to obtain a mixed solution containing the reaction product (Fe, Co)-BTC , cooled to room temperature (25°C). Add 20ml of DMF to the (Fe,Co)-BTC reaction product mixture obtained from the reaction, stir at room temperature for 2h, and use G 1 Funnel filtration removed most of the unreacted ligands, followed by drying to obtain crude solid (Fe,Co)-BTC material. Then the solid material was soaked in absolute ethanol, heat-treated at 110° C. for 24 hours, repeated twice, centrifuged, and dried to obtain a solid material. Then add 0.85g of ammonium fluoride and 75ml of water, heat at 70°C for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com