Cellulose modified activated carbon heavy metal adsorption material, and preparation method and application thereof

A technology for adsorbing materials and cellulose, which is applied in the field of biomass resource reuse and new materials with environmental functions, and achieves the effects of high adsorption rate, high capacity, reuse, and large pore volume.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

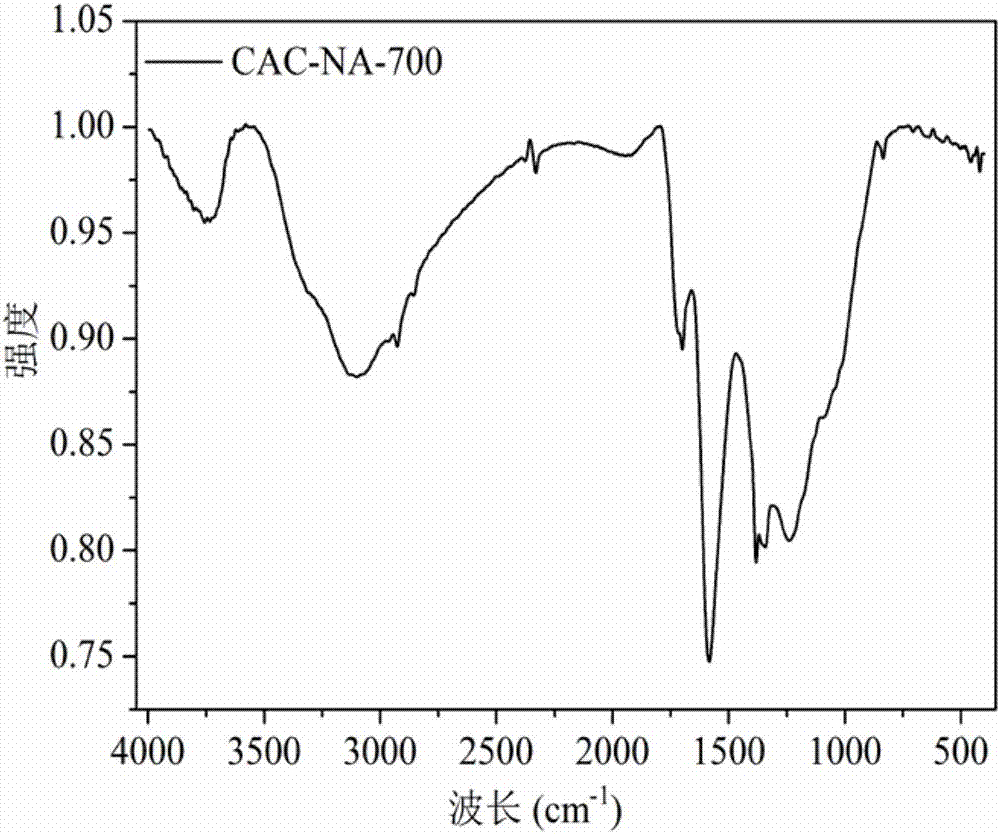

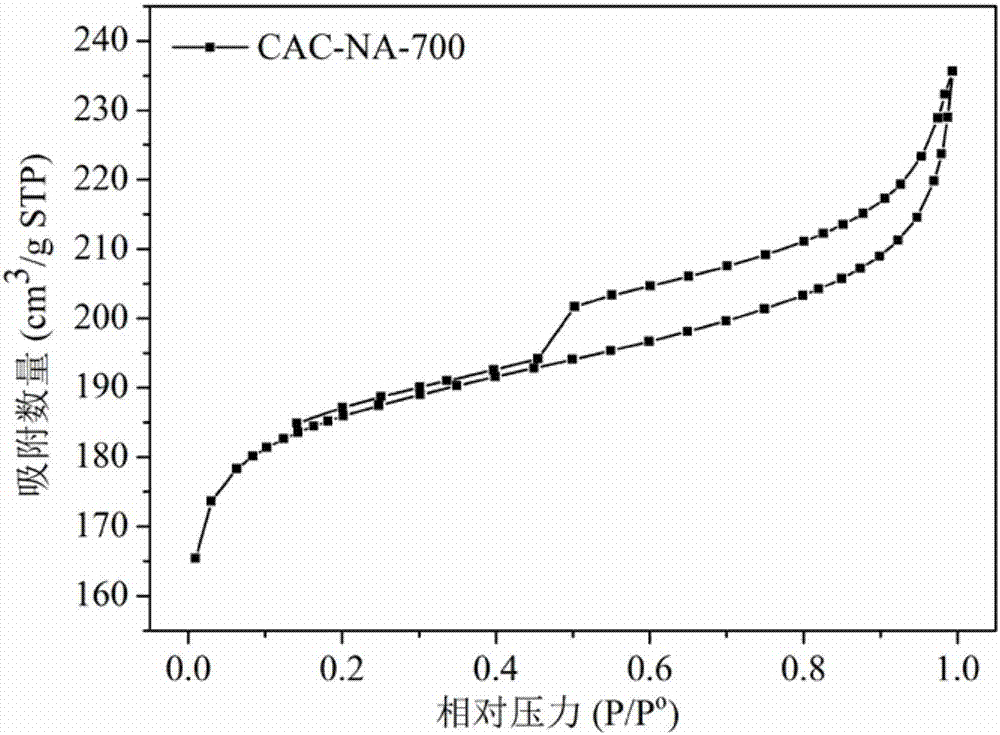

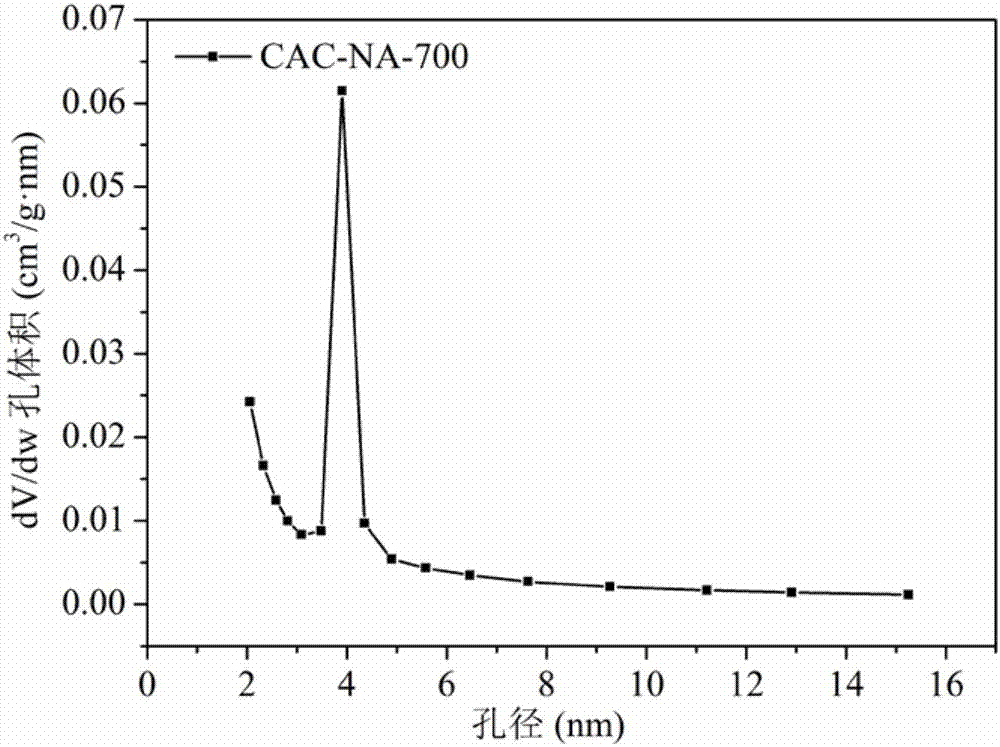

[0058] Example 1: Preparation of a cellulose-modified activated carbon adsorption material

[0059] The cellulose was placed in a tube furnace, and the temperature was raised to 300 °C at a rate of 5 °C / min. 2 The cellulose charcoal (CAC) was obtained by carbonizing under airflow for 60 minutes; the above cellulose charcoal and potassium hydroxide were mixed according to the mass ratio of 1:3, and deionized water was added thereto to keep the lye concentration of 30wt%. The above solution was dried in an oven at 80° C. to obtain cellulose activated carbon-potassium hydroxide (CAC-KOH); the above-mentioned cellulose activated carbon-alkali was placed in a tube furnace and heated at a rate of 5° C. / min to 700°C, under continuous N 2 Insulated under airflow for 60min to obtain cellulose activated carbon (CAC-700); mix the above-mentioned cellulose activated carbon with 30% concentrated nitric acid according to the mass ratio of 1:7.5, stir and react at 70°C oil bath temperature ...

Embodiment 2

[0061] Embodiment 2: Preparation of a kind of cellulose modified activated carbon adsorption material

[0062] The cellulose was placed in a tube furnace, and the temperature was raised to 250 °C at a heating rate of 3 °C / min. 2 The cellulose charcoal (CAC) was obtained by carbonizing under airflow for 80 minutes; the above-mentioned cellulose charcoal and potassium hydroxide were mixed according to the mass ratio of 1:2, and then deionized water was added to it to keep the lye concentration of 20wt%. The above solution was dried in an oven at 70°C to obtain cellulose activated carbon-potassium hydroxide (CAC-KOH); the above-mentioned cellulose activated carbon-alkali was placed in a tube furnace, and the temperature was raised to 550°C, under continuous N 2 Insulated under air flow for 240min to obtain cellulose activated carbon (CAC-550); mix the above-mentioned cellulose activated carbon with 20% concentrated nitric acid in a mass ratio of 1:10, stir and react for 2h at an...

Embodiment 3

[0063] Example 3: Preparation of a cellulose-modified activated carbon adsorption material

[0064] The cellulose was placed in a tube furnace, and the temperature was raised to 350 °C at a rate of 8 °C / min. 2 The cellulose charcoal (CAC) was obtained by carbonizing under airflow for 40 minutes; the above-mentioned cellulose charcoal and potassium hydroxide were mixed according to the mass ratio of 1:4, and then deionized water was added to it to maintain the lye concentration of 40wt%. The above solution was dried in an oven at 90°C to obtain cellulose activated carbon-potassium hydroxide (CAC-KOH); the above-mentioned cellulose activated carbon-alkali was placed in a tube furnace and heated at a rate of 8°C / min to 850°C, under continuous N 2 Insulated under air flow for 30min to obtain cellulose activated carbon (CAC-850); mix the above-mentioned cellulose activated carbon with 40% concentrated nitric acid in a mass ratio of 1:5, stir and react at 60°C for 4h in an oil bath...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com