Method for preparing amino group or quaternary ammonium salt functional silicon dioxide mesoporous spherical material

A technology of silica and quaternary ammonium salts, which is applied in the field of preparation of metal adsorption technology, and can solve problems such as harsh reaction conditions and limited number of organic functional groups

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] 0.207g C 18 h 37 HOOCCH 2 CH 2 CH(NH 2 )COOH was dissolved in 21g of deionized water, then 0.3g of Brij56 was added, and 0.179g of 3-aminopropyltriethoxysilane and 1.5g of tetraethoxysilane were added to the aqueous solution of the surfactant under stirring at 80°C The system was stirred for 10min, left to react at 80°C for 48 hours, centrifuged to obtain solid matter, then washed with deionized water, freeze-dried for one day, weighed 0.5g mesoporous silica material, and dissolved in 200ml ethanolamine (17vol %) in an ethanol solution for 12 hours, centrifuged, and vacuum-dried at room temperature. , to obtain hollow spheres of silicon dioxide with organic template removed and amino functionalized.

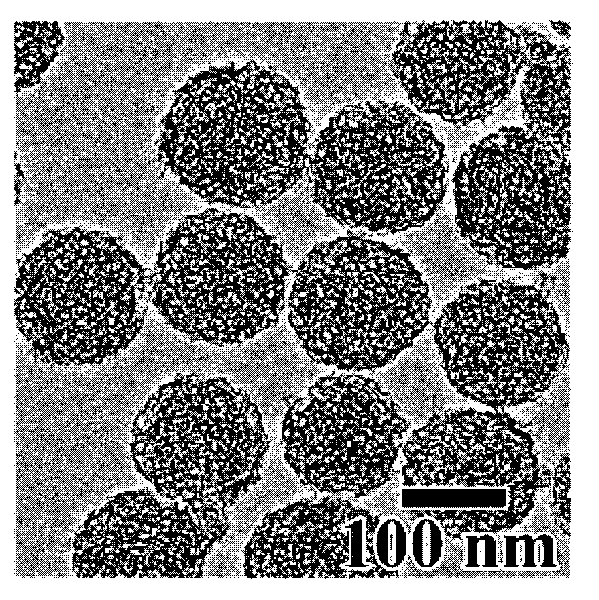

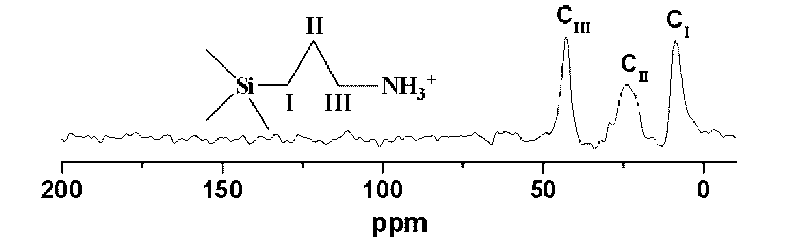

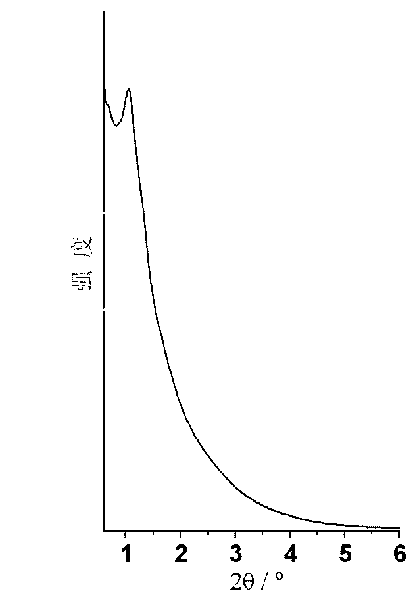

[0032]The amino or quaternary ammonium salt functionalized silica mesoporous spherical material was characterized by transmission electron microscope, solid nuclear magnetic field, X-ray diffraction, scanning electron microscope and nitrogen adsorption instrument. fi...

Embodiment 2

[0034] 0.207g C 18 h 37 HOOCCH 2 CH 2 CH(NH 2 )COOH was dissolved in 21g of deionized water, then 0.1g of Brij56 was added, and 0.179g of 3-aminopropyltriethoxysilane and 1.1g of tetramethoxysilane were added to the aqueous solution of the surfactant under stirring at 80°C The system was stirred for 10min, left to react at 80°C for 48 hours, centrifuged to obtain solid matter, then washed with deionized water, freeze-dried for one day, weighed 0.5g mesoporous silica material, and dissolved in 200ml ethanolamine (17vol %) in an ethanol solution for 12 hours, centrifuged, and vacuum-dried at room temperature. , to obtain hollow spheres of silicon dioxide with organic template removed and amino functionalized.

[0035] The amino-functionalized silica mesoporous spherical material was characterized by X-ray diffraction, solid-state NMR, nitrogen adsorption and transmission electron microscopy. It is obtained that the average particle diameter of the silica hollow mesoporous ...

Embodiment 3

[0037] 0.207g C 18 h 37 HOOCCH 2 CH 2 CH(NH 2 )COOH was dissolved in 21g of deionized water, then 0.5g of Brij56 was added, and 0.179g of 3-aminopropyltriethoxysilane and 2.3g of tetrabutoxysilane were added to the aqueous solution of the surfactant under stirring at 80°C The system was stirred for 10min, left to react at 80°C for 48 hours, centrifuged to obtain solid matter, then washed with deionized water, freeze-dried for one day, weighed 0.5g mesoporous silica material, and dissolved in 200ml ethanolamine (17vol %) in an ethanol solution for 12 hours, centrifuged, and vacuum-dried at room temperature. , to obtain hollow spheres of silicon dioxide with organic template removed and amino functionalized.

[0038] The amino-functionalized silica mesoporous spherical material was characterized by X-ray diffraction, solid-state NMR, nitrogen adsorption and transmission electron microscopy. It is obtained that the average particle diameter of the silica hollow mesoporous s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com