Process for treatment of PTA refining wastewater through high-selectivity adsorbent

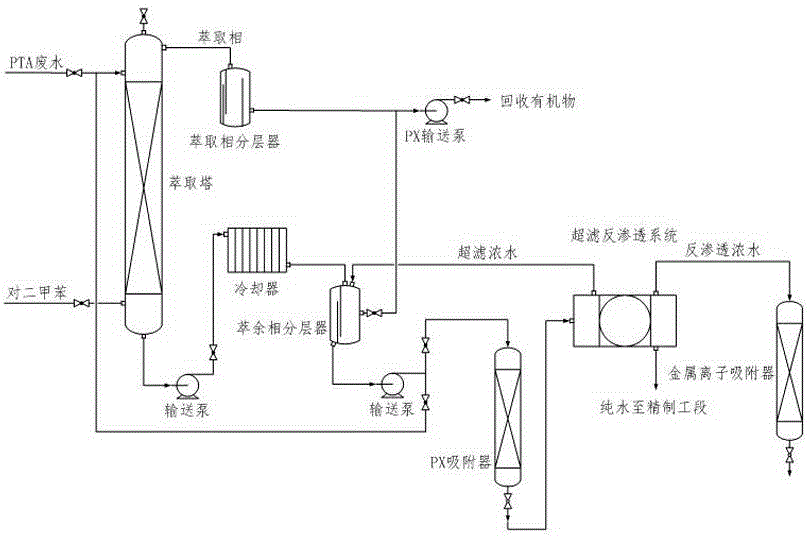

A highly selective and refined wastewater technology, applied in the field of water treatment, can solve the problems of long-term stable and effective operation of the process, erosion, etc., and achieve the effects of optimistic industrialization prospects, avoiding erosion and saving resources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

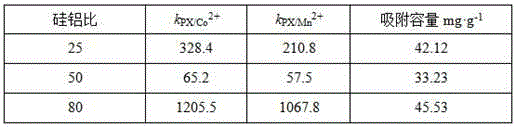

Embodiment 1

[0028] Filled with 50mg / L p-xylene (PX), 30mg / LCo 2+ and Mn 2+ Add 0.1g of molecular sieves with a silicon-aluminum ratio of 25, 50, and 80 after adding cobalt acetate to the iodine measuring bottle of 100ml of waste water, shake it in a constant temperature (25 degrees Celsius) water bath oscillator at 200r / min for 240min, and then shake it at 4000r / min Centrifuge for 10 min under the condition of min, analyze PX concentration by headspace sampling-gas chromatography, and analyze metal concentration by atomic absorption spectrophotometer. The obtained modified molecular sieves with different masses have the following table for the selectivity and adsorption capacity of adsorbing PX.

[0029]

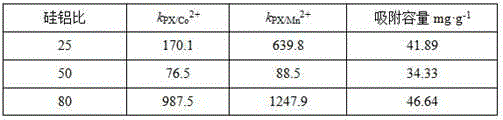

Embodiment 2

[0031] Filled with 50mg / L p-xylene (PX), 30mg / L Co 2+ and Mn 2+ Add 0.1g of molecular sieve with silicon-aluminum ratio of 25, 50, and 80 after adding manganese acetate to the iodine measuring bottle of 100ml of waste water, shake it in a constant temperature (25 degrees Celsius) water bath oscillator at 200r / min for 240min, and then shake it at 4000r / min Centrifuge for 10 min under the condition of min, analyze PX concentration by headspace sampling-gas chromatography, and analyze metal concentration by atomic absorption spectrophotometer. The obtained modified molecular sieves with different masses have the following table for the selectivity and adsorption capacity of adsorbing PX.

[0032]

Embodiment 3

[0034] Filled with 50mg / L p-xylene (PX), 30mg / L Co 2+ and Mn 2+ After adding ammonium chloride to the iodine measuring bottle of 100ml of waste water, 0.1g of molecular sieve with a silicon-aluminum ratio of 25, 50, and 80 was added, shaken at 200r / min in a constant temperature (25 degrees Celsius) water bath oscillator for 240min, and then heated at 4000r Centrifuge for 10 min under the condition of / min, analyze PX concentration by headspace sampling-gas chromatography, and analyze metal concentration by atomic absorption spectrophotometer. The obtained modified molecular sieves with different masses have the following table for the selectivity and adsorption capacity of adsorbing PX.

[0035]

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com