Treatment method for heavy-metal-containing wastewater

A treatment method and technology for heavy metals, applied in multi-stage water treatment, water/sewage treatment, water/sewage multi-stage treatment, etc., can solve the problems of easy oxidation failure, frequent regeneration and high operating costs of ion exchangers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

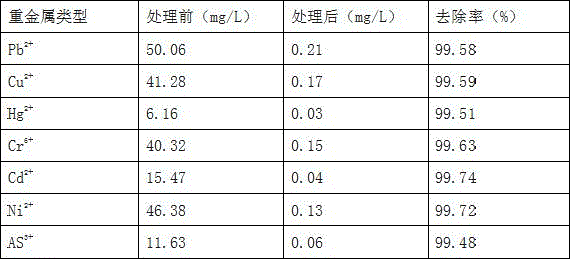

[0022] Embodiment 1: a kind of processing method that contains heavy metal wastewater, comprises the steps:

[0023] 1) Add the heavy metal adsorbent to the heavy metal-containing wastewater, fully stir or shake for 3 hours; centrifuge the heavy metal adsorbent or leave it to stand until the heavy metal adsorbent precipitates to obtain a supernatant; the amount of the heavy metal adsorbent is 1 / 2 of the weight of the heavy metal-containing wastewater 1%;

[0024] 2) Add a complexing agent to the supernatant of step 1), stir or shake for 2 hours; then add a reducing agent and stir or shake for 2 hours; then adjust the pH value to 12 with sodium hydroxide solution, heat to 65°C, and fully React for 2.5 hours, and carry out solid-liquid separation; the complexing agent is a combination of sodium citrate, sodium edetate and potassium sodium tartrate, and the weight ratio of the three is 1:1:1; The mass ratio of the heavy metal to the complexing agent is 1:5; the reducing agent is...

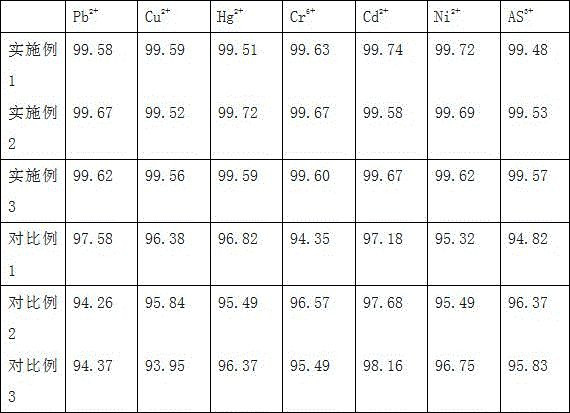

Embodiment 2

[0028] Embodiment 2 A kind of processing method that contains heavy metal wastewater, comprises the steps:

[0029] 1) Add the heavy metal adsorbent to the heavy metal-containing wastewater, fully stir or shake for 4 hours; centrifuge the heavy metal adsorbent or leave it to stand until the heavy metal adsorbent is precipitated to obtain a supernatant; the amount of the heavy metal adsorbent is 1 / 2 of the weight of the heavy metal-containing wastewater 1.5%;

[0030]2) Add complexing agent to the supernatant of step 1), fully stir or shake for 3 hours; then add reducing agent and stir or shake for 3 hours; then adjust the pH value to 10 with sodium hydroxide solution, heat to 70°C, fully React for 3 hours and carry out solid-liquid separation; the complexing agent is a combination of sodium citrate, sodium edetate and potassium sodium tartrate, and the weight ratio of the three is 1:1:1; the heavy metal in the heavy metal-containing wastewater The mass ratio to the complexing...

Embodiment 3

[0034] Embodiment 3 A kind of processing method that contains heavy metal wastewater, comprises the steps:

[0035] 1) Add the heavy metal adsorbent to the heavy metal-containing wastewater, fully stir or shake for 5 hours; centrifuge the heavy metal adsorbent or leave it to stand until the heavy metal adsorbent is precipitated to obtain a supernatant; the amount of the heavy metal adsorbent is the weight of the heavy metal-containing wastewater 2%;

[0036] 2) Add complexing agent to the supernatant of step 1), fully stir or shake for 2.5h; then add reducing agent and stir or shake for 2.5h; then adjust the pH value to 8 with sodium hydroxide solution, and heat to 75°C , fully reacted for 3 hours, and carried out solid-liquid separation; the complexing agent is a combination of sodium citrate, sodium edetate and potassium sodium tartrate, and the weight ratio of the three is 1:1:1; The mass ratio of the heavy metal to the complexing agent is 1:5; the reducing agent is a comb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com