Self-seam-filling repairing method for bent position of metal plate

A metal plate, self-replenishing technology, applied in the field of metal plate bending, can solve problems such as shortened service life, low repair efficiency, and prone to cracks, and achieve the effects of reducing health impacts, reducing waste, and improving repair efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

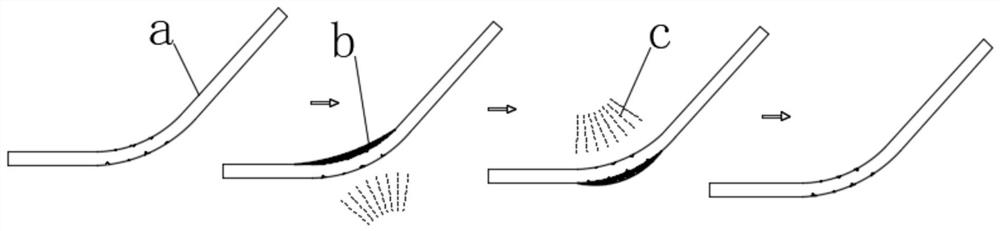

[0045] see figure 1 , a method for self-repairing seams at the bend of a metal plate, comprising the following steps:

[0046] S1. First, the metal plate is derusted, cleaned and dried, and then bent by a bending machine;

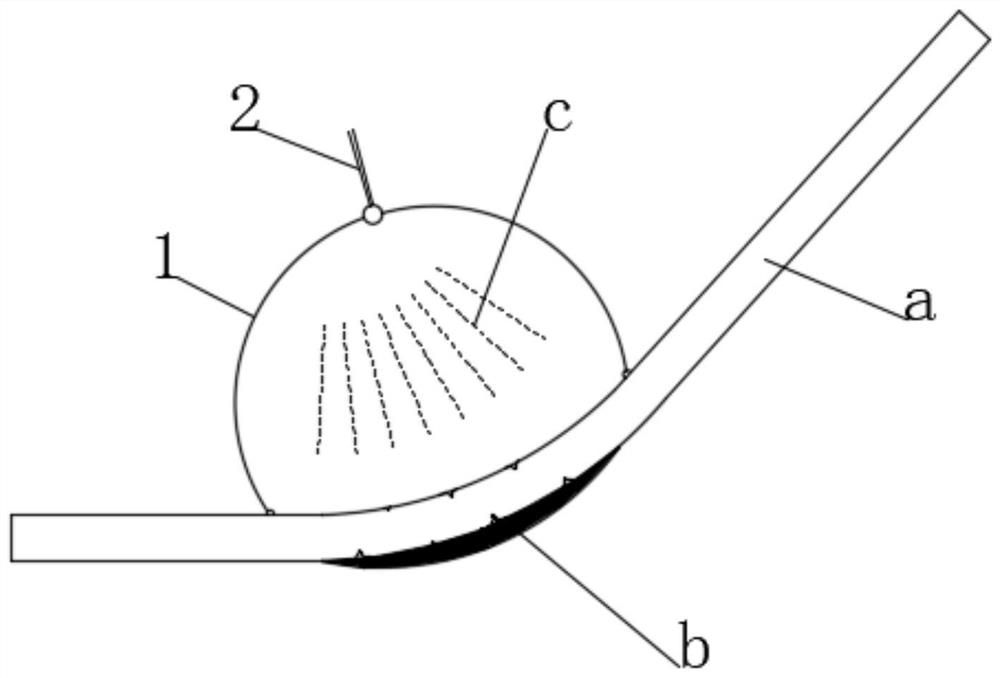

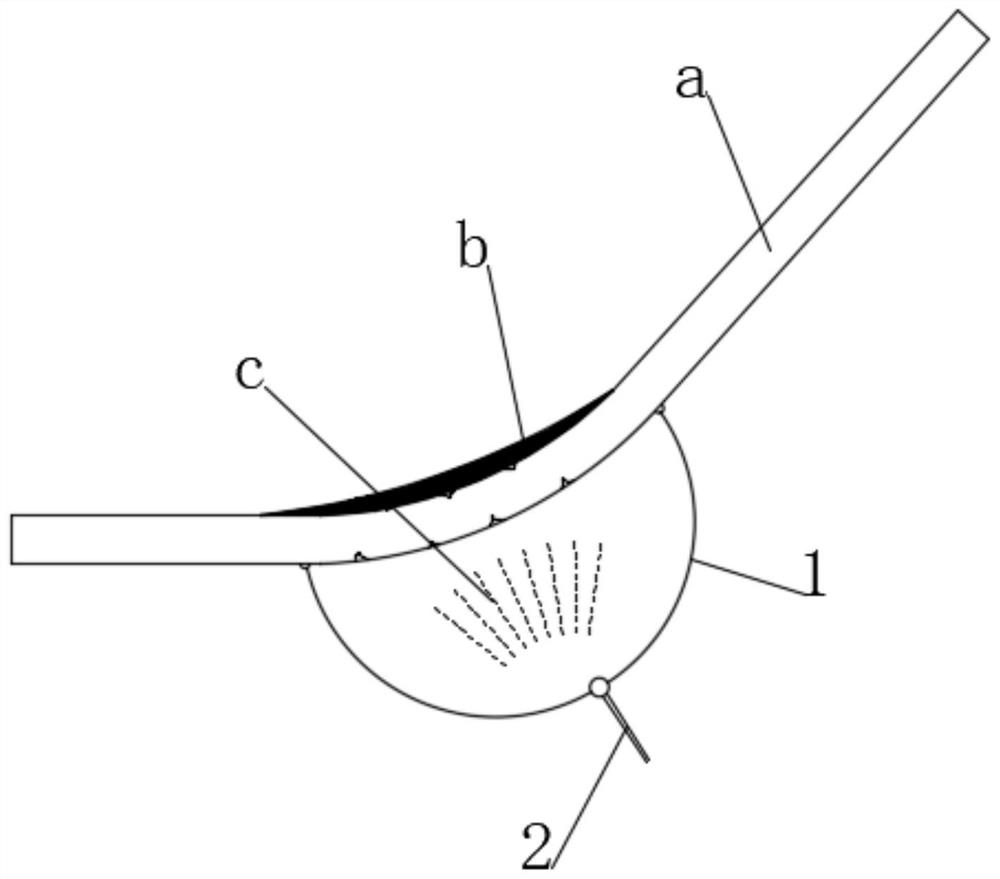

[0047] S2. Please refer to image 3 , laying a layer of soft magnets on the inner wall of the bend, and then covering the bend with a diffuse and restrained suction cover 1, and then spraying metal powder on the outer wall;

[0048] S3. Afterwards, fixed-point laser heating is performed on the outer wall of the metal plate bend, so that the seam repairing metal powder and the outer surface of the metal plate bend are slightly melted and condensed together, and the seam repair of the outer wall of the metal plate bend is completed;

[0049] S4. Please refer to figure 2 , laying a layer of soft magnets on the outer wall of the bend, and then covering the bend with a diffuse and restrained suction cover 1, and then spraying metal powder on the inner wall o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com