Photosensitive printing ink for 3D glass, preparation method thereof and preparation method of photosensitive coating

A photosensitive ink and photosensitive coating technology, applied in ink, applications, household appliances, etc., can solve the problems of unprintable 3D glass, pollute the environment, and high cost, and achieve the effects of protecting human health, reducing corrosion, and low maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] According to another aspect of the present invention, there is also provided a method for preparing a photosensitive ink for 3D glass, including the above photosensitive ink for 3D glass, including the following steps: UV water-soluble resin, hydrophilic UV monomer , water-based photoinitiator, photoacid generator, pigments, fillers, and additives are mixed, stirred and ground to a particle size below 5 μm to obtain component A; water-soluble epoxy resin and water are mixed to obtain component B, and A Components are mixed with component B to obtain photosensitive ink for 3D glass. The above method for preparing photosensitive ink for 3D glass is simple and easy to implement, has high yield and low cost, and is suitable for mass production, and the prepared ink is suitable for surface decoration of 3D glass.

[0035] While stirring, add UV water-soluble resin, hydrophilic UV monomer, water-based photoinitiator, photoacid generator, pigment, filler, and additive in turn,...

Embodiment 1

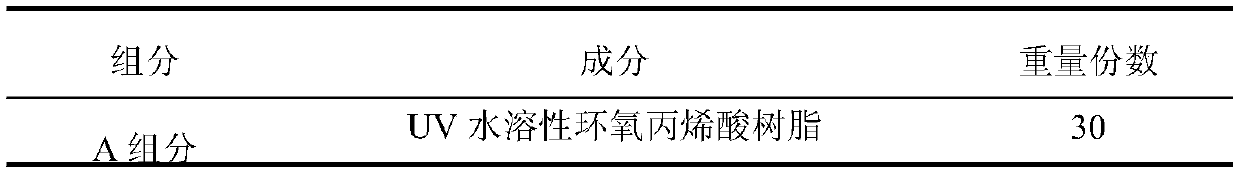

[0043] A preferred embodiment of the present invention provides a photosensitive ink for 3D glass, and the composition of component A and component B is shown in Table 1.

[0044] The photosensitive ink that is used for 3D glass of table 1 embodiment 1

[0045]

[0046]

[0047] Mix component A and component B at a ratio of 10:1 to obtain photosensitive ink for 3D glass

[0048] Preparation method of photosensitive ink for 3D glass

[0049] While stirring, add UV water-soluble epoxy acrylic resin, UV water-soluble polyurethane resin, ACMO, PEG[400]DA, PE[EO] in sequence 15 TA, HMPP-1, TX-3S, titanium dioxide, 2,1,4-diazonaphthoquinone sulfonate, 2-methyl-2-p-tolylsulfonyl acetophenone, barium sulfate, additives, stirred The rotating speed is 1000 rpm, and after mixing evenly, disperse at a rotating speed of 1500 rpm for 20 minutes, grind on a sand mill until the particle size is less than 5 μm, and obtain component A; while stirring, add water-based hydantoin epoxy res...

Embodiment 2

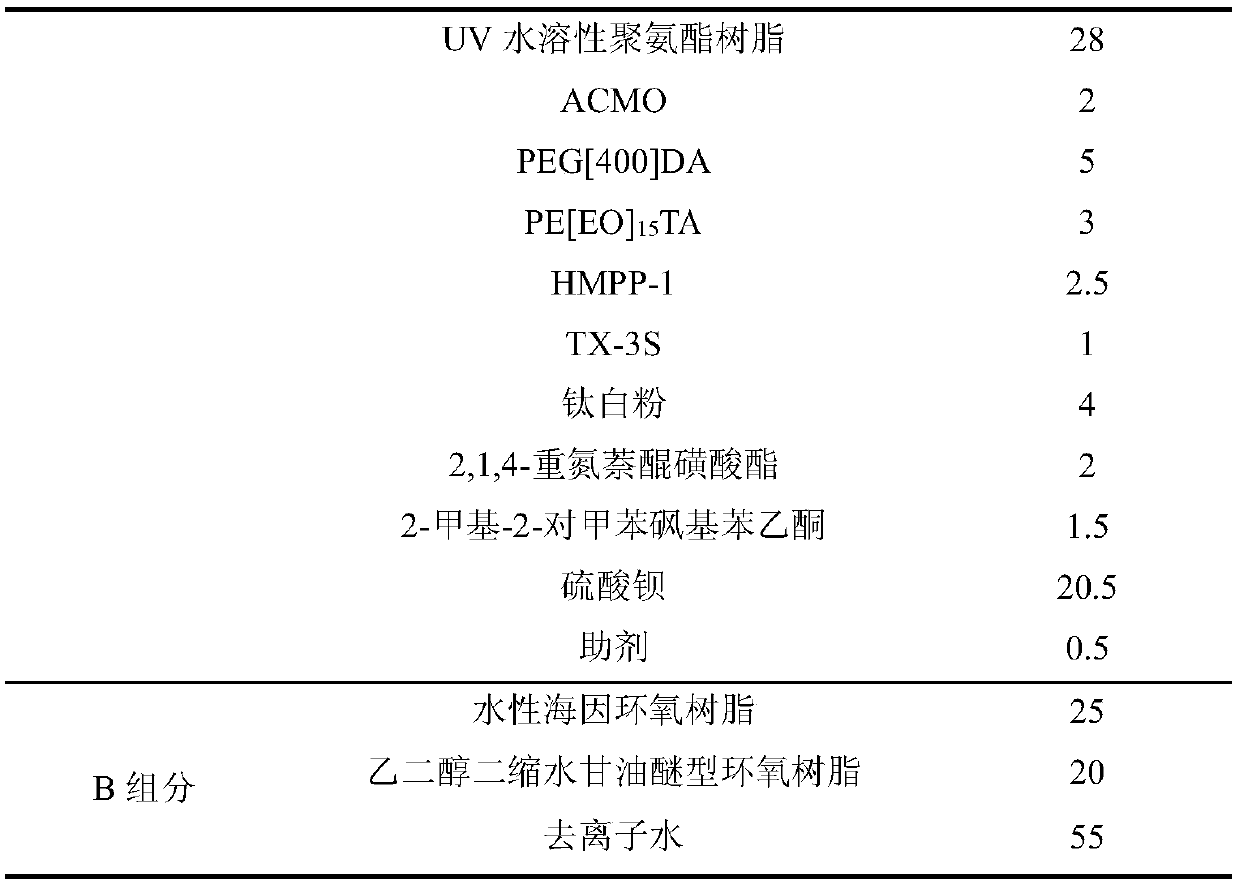

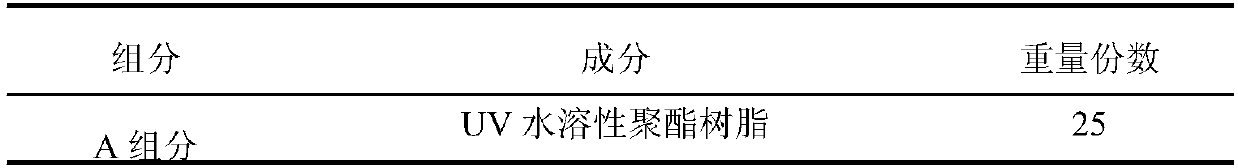

[0053] A preferred embodiment of the present invention provides a photosensitive ink for 3D glass. The composition of component A and component B is shown in Table 2.

[0054] The photosensitive ink that is used for 3D glass of table 2 embodiment 2

[0055]

[0056]

[0057] Mix component A and component B at a ratio of 9:1 to obtain photosensitive ink for 3D glass

[0058] The preparation method of the photosensitive ink for 3D glass is the same as the preparation method of the photosensitive ink for 3D glass in Example 1.

[0059] Preparation method of photosensitive coating

[0060] (1) Dilute the photosensitive ink used for 3D glass with 100% deionized water, stir well, and filter with 500 mesh; (2) Spray the first time on the surface of the 3D glass substrate and bake at 85°C 10min, with 1300mj / cm 2 UV energy curing, and then 25 ℃, 1.5kg / cm 2 Spray and develop with tap water for 60 seconds, and cure at 170°C for 6 minutes to form the bottom layer; (3) Spray the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| adhesivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com