Environment-friendly, acid-proof and high-temperature-resistant exterior wall coating material and preparation method thereof

A technology for building exterior walls and high temperature resistance, used in epoxy resin coatings, anti-corrosion coatings, fire-resistant coatings, etc., can solve problems such as unfavorable human health, environmental pollution, waste of coatings, etc., to achieve benefits for workers' health and reduce formaldehyde content. , the effect of long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

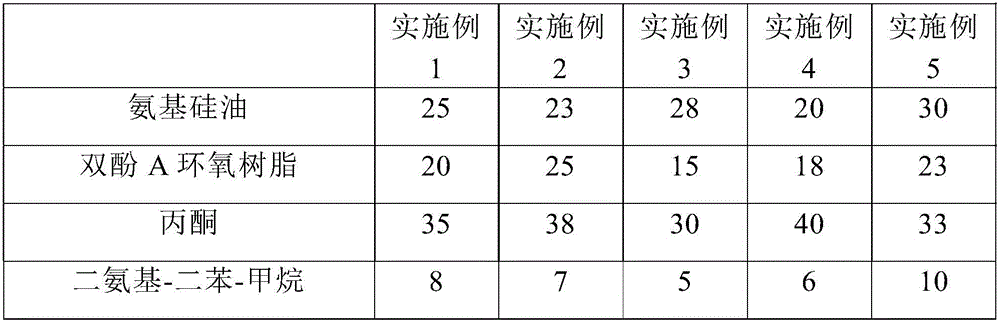

[0024] The present invention will be further described below through specific examples, but the examples do not limit the protection scope of the present invention.

[0025] An environment-friendly, acid-resistant and high-temperature-resistant building exterior wall paint provided by the present invention includes the following components by weight: silicone modified epoxy resin: 20-30 parts, bisphenol A epoxy resin: 10-15 parts Parts, thermal insulation filler: 5-10 parts, nano silicon oxide: 5-10 parts, anti-rust pigment: 10-15 parts, carboxymethyl cellulose: 10-20 parts, acetone: 5-10 parts, nano-calcium carbonate : 1-5 parts, butyl acetate: 1-5 parts, co-solvent: 20-30 parts, deionized water: 30-40 parts, dibutyl phthalate: 5-10 parts, pH regulator: 1 ~5 parts, dispersant: 1~5 parts, coalescent agent: 1~5 parts, thickener: 1~5 parts.

[0026] Further, the coating includes the following components by weight: silicone modified epoxy resin: 25-30 parts, bisphenol A epoxy re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com