Environment-friendly wear-proof two-component plastic cement paint and preparation method thereof

A plastic paint, two-component technology, applied in the direction of fireproof coatings, polyurea/polyurethane coatings, coatings, etc., can solve the problems of unfavorable human health, waste of plastic paint, economic losses, etc., so as to benefit the health of workers and improve The effect of hardness and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below through specific examples, but the examples do not limit the protection scope of the present invention.

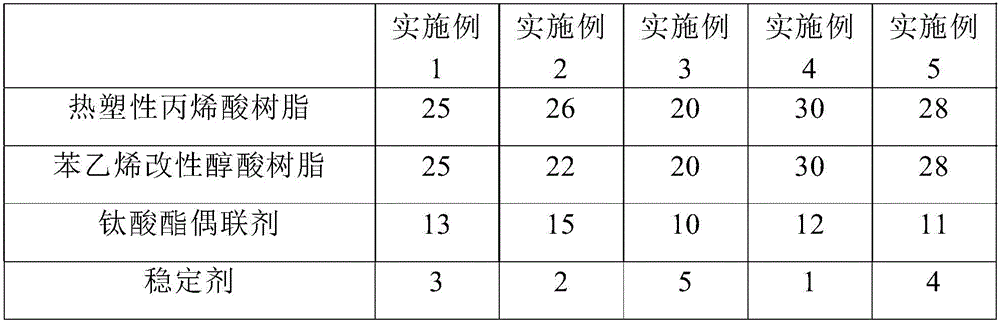

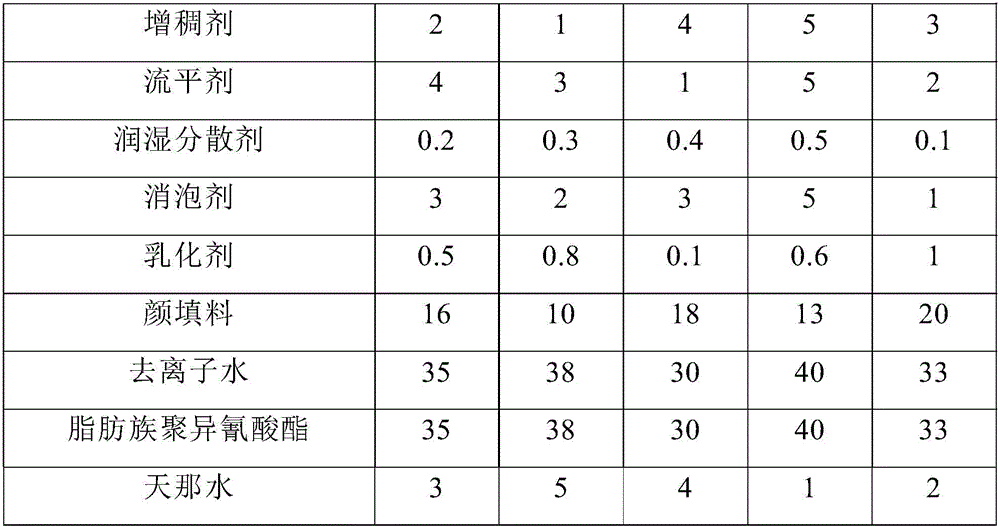

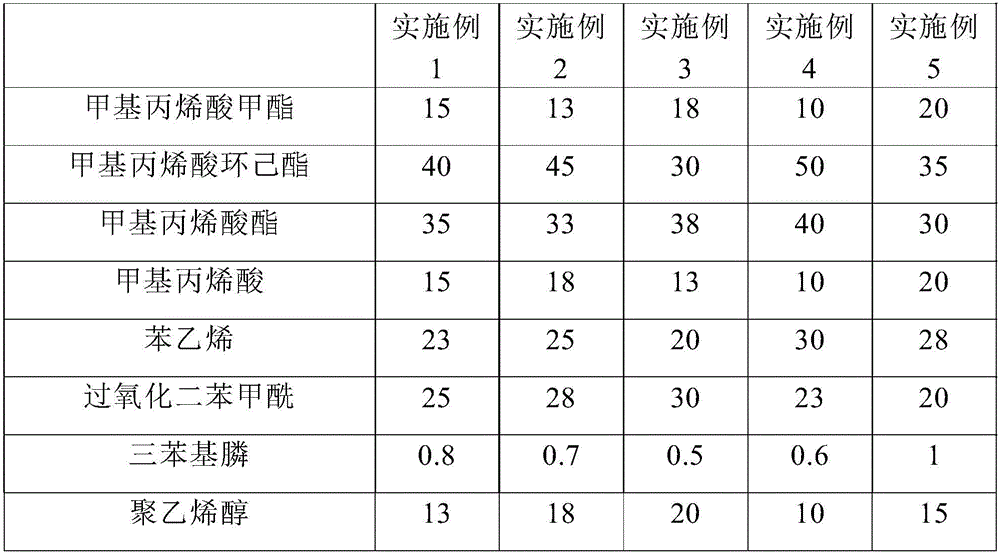

[0028]An environmentally friendly and wear-resistant two-component plastic paint provided by the present invention, the plastic paint includes the following components in parts by weight: Component A: styrene modified alkyd resin: 20-30 parts, thermoplastic acrylic resin: 20-30 parts 30 parts, titanate coupling agent: 10-15 parts, stabilizer: 1-5 parts, thickener: 1-5 parts, leveling agent: 1-5 parts, wetting and dispersing agent: 0.1-0.5 parts , defoamer: 1-5 parts, emulsifier: 0.1-1 parts, pigments and fillers: 10-20 parts, deionized water: 30-40 parts; B component: aliphatic polyisocyanate: 30-40 parts, day That water: 1 to 5 parts.

[0029] Further, the plastic paint includes the following components by weight: component A: styrene-modified alkyd resin: 25-30 parts, thermoplastic acrylic resin: 20-25 parts, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com