Environment-friendly high-hardness acrylic acid amino baking varnish and preparation method thereof

A kind of acrylic acid amino, high hardness technology, applied in the direction of coating, anti-corrosion coating, etc., can solve the problems of unfavorable human health, waste of baking paint, pollution of the environment, etc., and achieve the benefits of workers' health, long service life and enhanced anti-corrosion ability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described through specific examples below, but the examples do not limit the protection scope of the present invention.

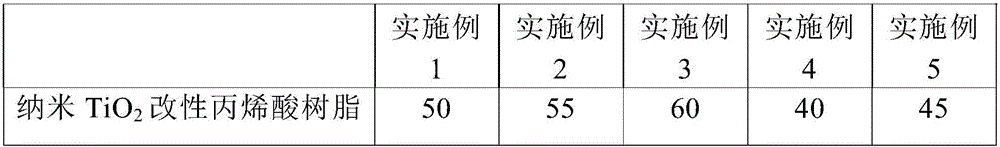

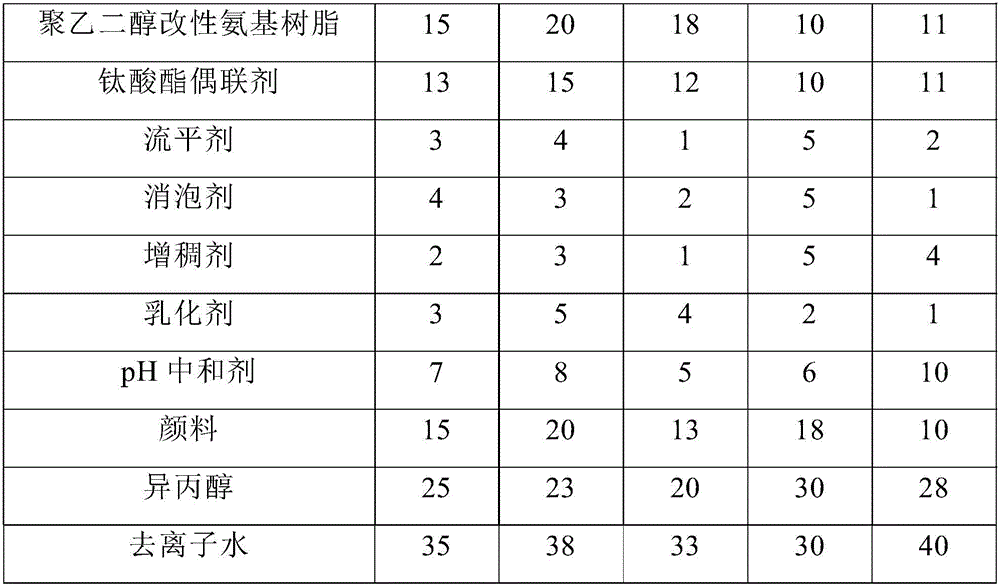

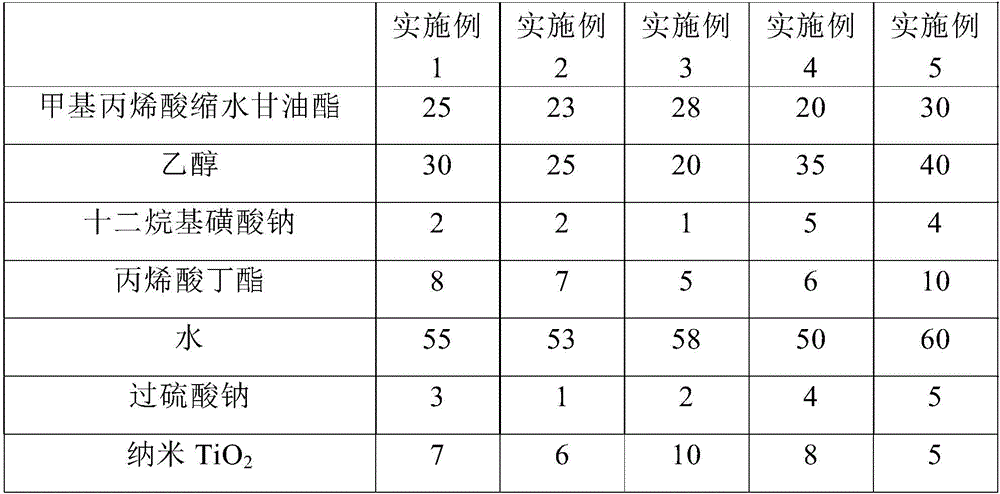

[0031] An environmentally friendly high-hardness acrylic amino clear baking paint provided by the present invention, the baking paint includes the following components by weight: nano TiO 2 Modified acrylic resin: 40-60 parts, polyethylene glycol modified amino resin: 10-20 parts, titanate coupling agent: 10-15 parts, leveling agent: 1-5 parts, defoaming agent: 1 ~5 parts, thickener: 1~5 parts, emulsifier: 1~5 parts, pH neutralizer: 5~10 parts, pigment: 10~20 parts, isopropanol: 20~30 parts, deionized water : 30-40 copies.

[0032] Further, the baking paint includes the following components by weight: nano TiO 2 Modified acrylic resin: 40-50 parts, polyethylene glycol modified amino resin: 10-15 parts, titanate coupling agent: 13-15 parts, leveling agent: 2-5 parts, defoaming agent: 3 ~5 parts, thickener: 1~3 parts, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com