Dust inhibition agent for inhibiting dust suspension, and preparation method thereof

A dust suppressant and dust technology, applied in the field of dust suppressant for suppressing dust suspension and its preparation, can solve the problems of small dust fixation effect, high environmental toxicity, fast water evaporation, etc., to reduce material loss, reduce dust pollution, The effect of protecting the health of the body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

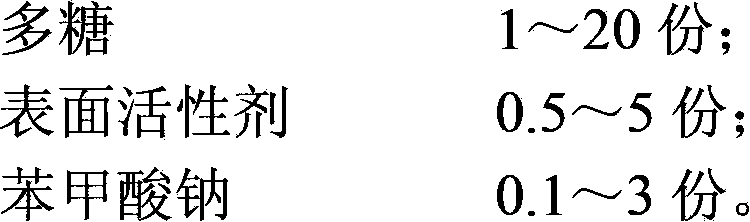

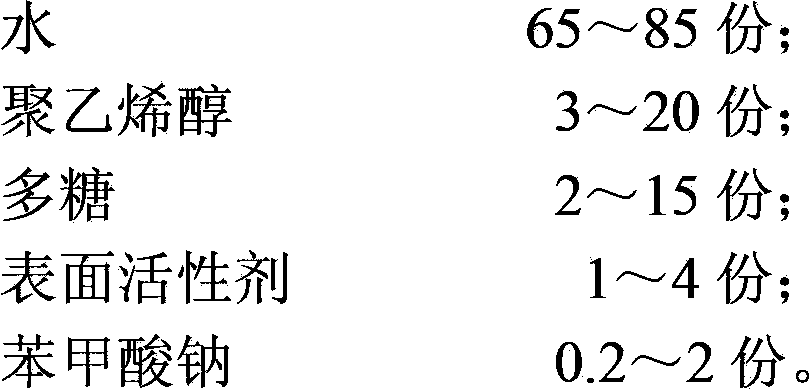

Method used

Image

Examples

Embodiment 1

[0020] A dust suppressant for suppressing dust suspension, the components and weight of the dust suppressant are: water 85Kg; polyvinyl alcohol 8.5Kg; polysaccharide 3.5Kg; surfactant 2.5Kg; sodium benzoate 0.5Kg. Wherein the water is tap water, the polysaccharide is carboxymethyl cellulose, and the surfactant is sodium dodecylsulfonate.

[0021] A preparation method of a dust suppressant for suppressing dust suspension. The method is to first add water to a reaction kettle according to the ratio of parts by weight, heat to 70°C, and then slowly add polyvinyl alcohol, polysaccharide, and surfactant respectively. 1. Sodium benzoate, stirred and heated until completely dissolved, mixed evenly, and after 20 minutes of heat preservation, the finished product of the dust suppressant for suppressing the suspension of dust was obtained. The finished product is diluted 10 times and sprayed on the surface of the mound of a construction site, the spraying amount is 2.0kg / m2, after 8 hou...

Embodiment 2

[0023] A dust suppressant for suppressing dust suspension, the components and weight of the dust suppressant are: water 50Kg; polyvinyl alcohol 2Kg; polysaccharide 1Kg; surfactant 0.5Kg; sodium benzoate 0.1Kg. Wherein the water is tap water, the polysaccharide is sodium carboxyethyl cellulose, and the surfactant is sodium tetradecylbenzenesulfonate.

[0024] A preparation method of a dust suppressant for suppressing dust suspension. The method is to first add water to a reaction kettle according to the ratio of parts by weight, heat it to 60°C, and then slowly add polyvinyl alcohol, polysaccharide, and surfactant respectively. 1. Sodium benzoate, stirred and heated until completely dissolved, mixed uniformly, and after 15 minutes of heat preservation, the finished product of the dust suppressant for suppressing the suspension of dust was obtained. The finished product is diluted 10 times and sprayed on the road surface of a construction site. The spraying amount is 1.2kg / m2. C...

Embodiment 3

[0026] A kind of dust suppressant for suppressing the suspension of dust, the components and weight of the dust suppressant are: water 70Kg; polyvinyl alcohol 16Kg; starch 11Kg; sodium pentadecylbenzenesulfonate 2.5Kg; sodium benzoate 1.5Kg Kg. Wherein the water is tap water, the polysaccharide is sodium carboxyethyl cellulose, and the surfactant is sodium tetradecylbenzenesulfonate.

[0027] A preparation method of a dust suppressant for suppressing dust suspension. The method is to first add water to a reaction kettle according to the ratio of parts by weight, heat to 80°C, and then slowly add polyvinyl alcohol, polysaccharide, and surfactant respectively. 1. Sodium benzoate, stirred and heated until completely dissolved, mixed evenly, and after 30 minutes of heat preservation, the finished product of the dust suppressant for suppressing the suspension of dust was obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com