Sewage treatment process and treatment device combining electroflotation and electric flocculation

A sewage treatment equipment, sewage treatment technology, applied in flotation water / sewage treatment, water / sewage treatment, neutralization water / sewage treatment, etc. and other problems, to achieve the effect of saving water load change adaptability, good effect, and complete oil removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below according to the accompanying drawings and specific embodiments, but the embodiments of the present invention are not limited thereto.

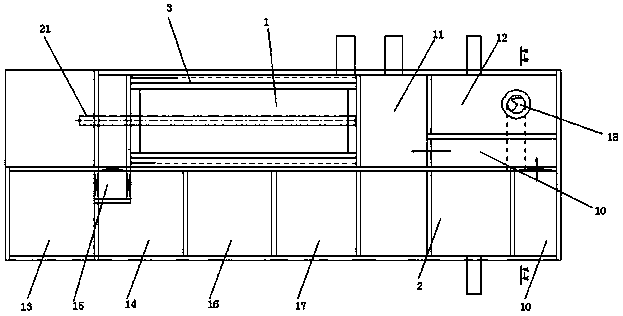

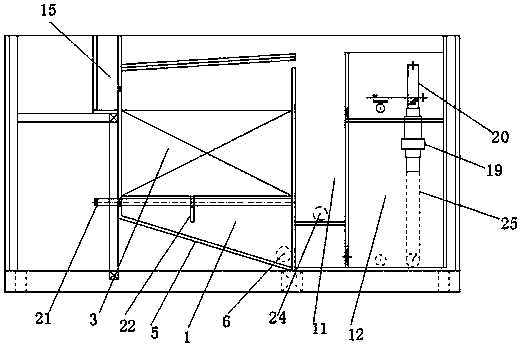

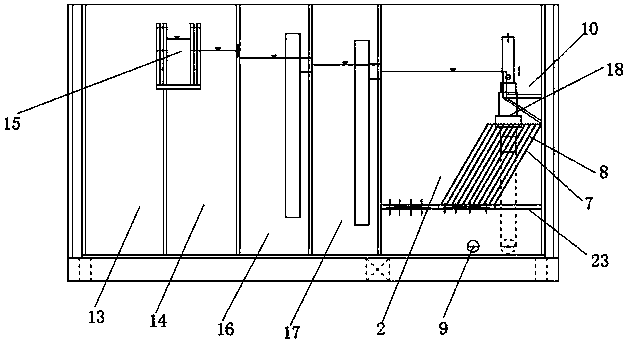

[0034] Such as Figure 1 to Figure 5 As shown, a sewage treatment process of electric flotation combined with electric flocculation, including electric flocculation and electric flotation, sewage enters electric flotation for treatment after electrocoagulation;

[0035] Electrocoagulation involves the following steps:

[0036] (1) Bond breaking: By applying voltage to multiple electrode plates set at intervals, the distance between each two electrode plates is 10mm-20mm or 20mm-50mm, breaking and decomposing various organic substances and complex heavy metal complexes in sewage Binding chains or chelating chains, breaking large molecules into small molecules;

[0037](2) Oxidation-reduction: The broken small molecules move with the electron flow in water to obtain or lose electron...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com