Oil removing machine for grip of moving spanner of car

A technology of adjustable wrench and handle, applied in cleaning methods and utensils, cleaning methods using tools, chemical instruments and methods, etc., can solve problems such as low work efficiency and cumbersome operation process, and achieve high work efficiency and simple operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

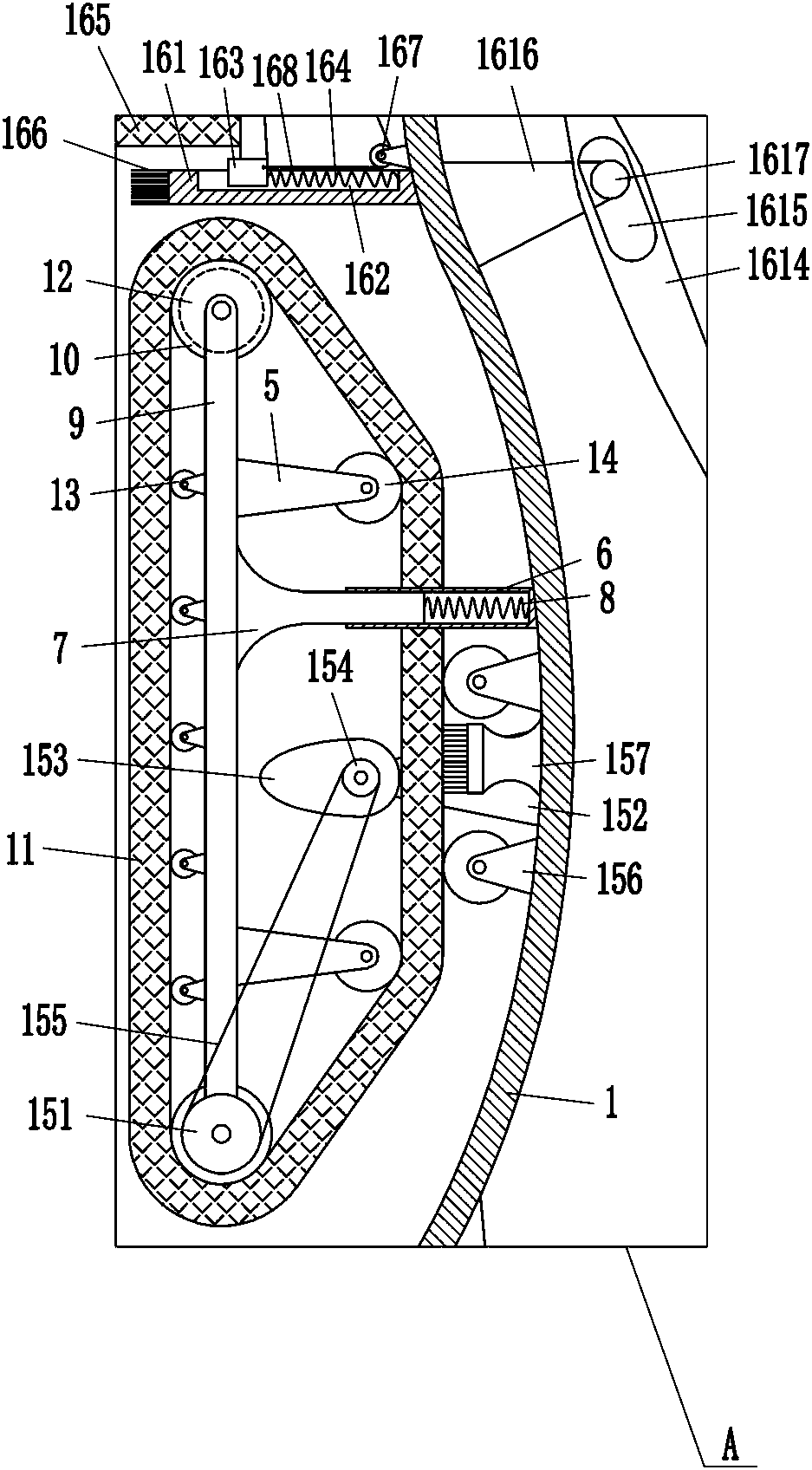

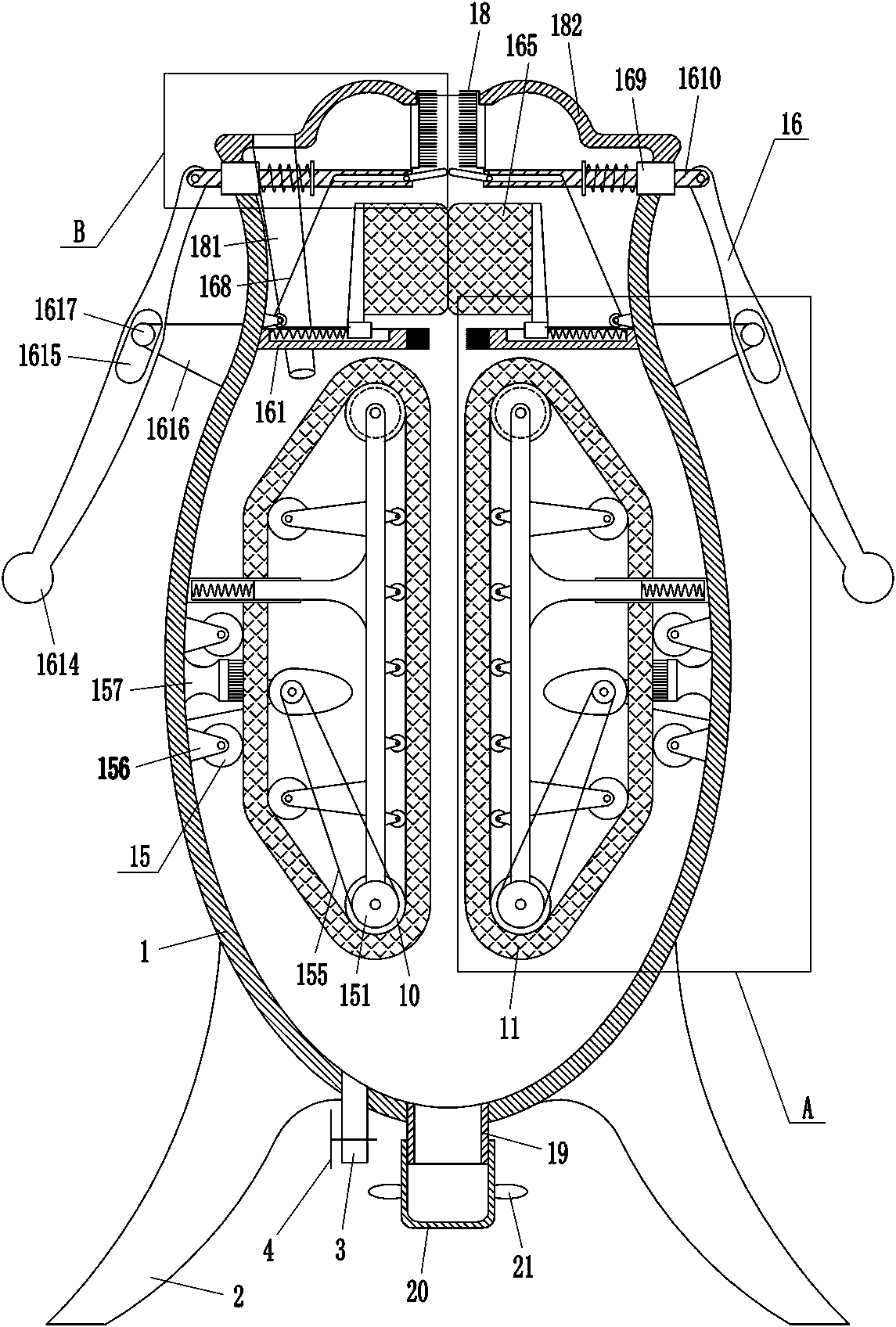

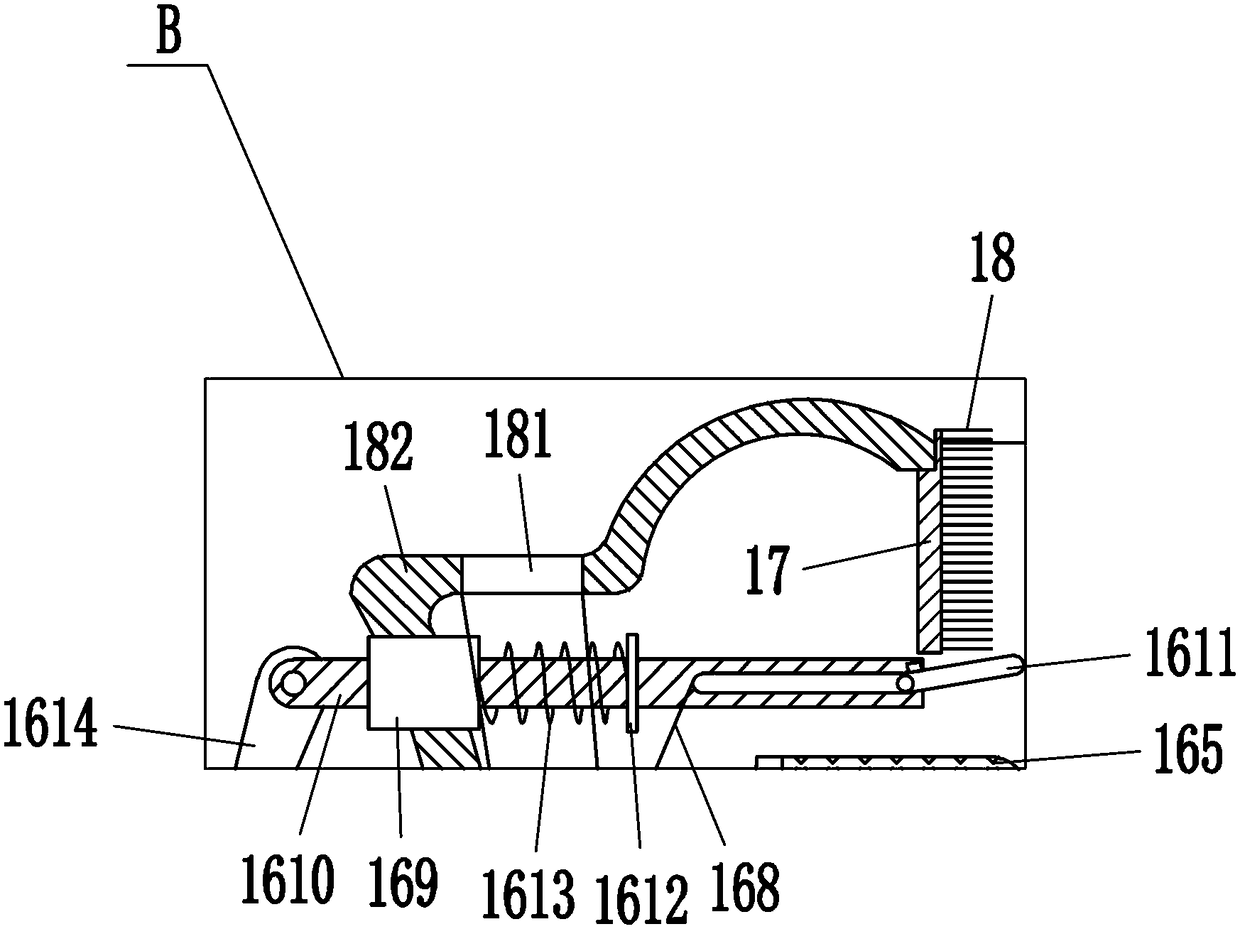

[0021] A kind of automobile adjustable wrench handle degreasing machine, such as Figure 1-3As shown, it includes box body 1, outrigger 2, drain pipe 3, valve 4, installation seat 5, sleeve 6, sleeve rod 7, first spring 8, installation frame 9, roller 10, sponge conveyor belt 11, motor 12. Small support roller 13, large support roller 14 and scrubbing mechanism 15, outriggers 2 are fixedly connected to the left and right sides of the bottom of the box body 1, and the drain pipe 3 is connected to the left side of the bottom of the box body 1, and the drain pipe 3 is located on the left side of the support. On the right side of the leg 2, a valve 4 is installed on the drain pipe 3, and the left and right sides of the middle part of the box body 1 are connected with a square sleeve 6, and the sleeve 6 is provided with a square sleeve rod 7, the sleeve rod 7 and the inner wall of the sleeve 6 are connected with a first spring 8, and the inner ends of the two sleeve rods 7 are conn...

Embodiment 2

[0023] A kind of automobile adjustable wrench handle degreasing machine, such as Figure 1-3 As shown, it includes box body 1, outrigger 2, drain pipe 3, valve 4, installation seat 5, sleeve 6, sleeve rod 7, first spring 8, installation frame 9, roller 10, sponge conveyor belt 11, motor 12. Small support roller 13, large support roller 14 and scrubbing mechanism 15, outriggers 2 are fixedly connected to the left and right sides of the bottom of the box body 1, and the drain pipe 3 is connected to the left side of the bottom of the box body 1, and the drain pipe 3 is located on the left side of the support. On the right side of the leg 2, a valve 4 is installed on the drain pipe 3, and the left and right sides of the middle part of the box body 1 are connected with a square sleeve 6, and the sleeve 6 is provided with a square sleeve rod 7, the sleeve rod 7 and the inner wall of the sleeve 6 are connected with a first spring 8, and the inner ends of the two sleeve rods 7 are con...

Embodiment 3

[0026] A kind of automobile adjustable wrench handle degreasing machine, such as Figure 1-3 As shown, it includes box body 1, outrigger 2, drain pipe 3, valve 4, installation seat 5, sleeve 6, sleeve rod 7, first spring 8, installation frame 9, roller 10, sponge conveyor belt 11, motor 12. Small support roller 13, large support roller 14 and scrubbing mechanism 15, outriggers 2 are fixedly connected to the left and right sides of the bottom of the box body 1, and the drain pipe 3 is connected to the left side of the bottom of the box body 1, and the drain pipe 3 is located on the left side of the support. On the right side of the leg 2, a valve 4 is installed on the drain pipe 3, and the left and right sides of the middle part of the box body 1 are connected with a square sleeve 6, and the sleeve 6 is provided with a square sleeve rod 7, the sleeve rod 7 and the inner wall of the sleeve 6 are connected with a first spring 8, and the inner ends of the two sleeve rods 7 are con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com