Meat powder production equipment and technology

A technology of production equipment and production process, which is applied in the field of meat powder production equipment and process, can solve the problems of insufficiently extracted animal tissues and organs with high protein content, poor working environment for staff, and affecting the health of staff, so as to facilitate the drying process and reduce Air pollution, the effect of avoiding the loss of nutrients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

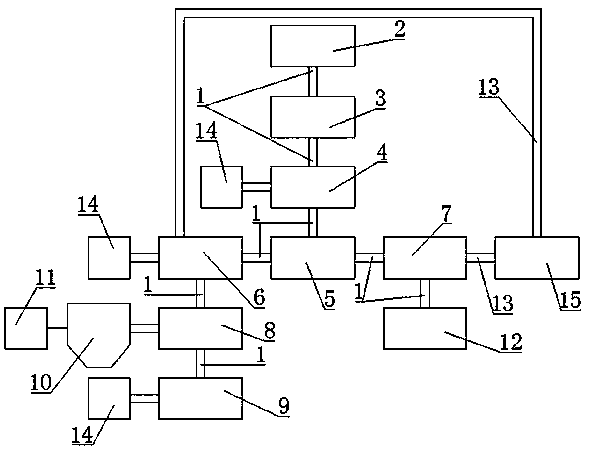

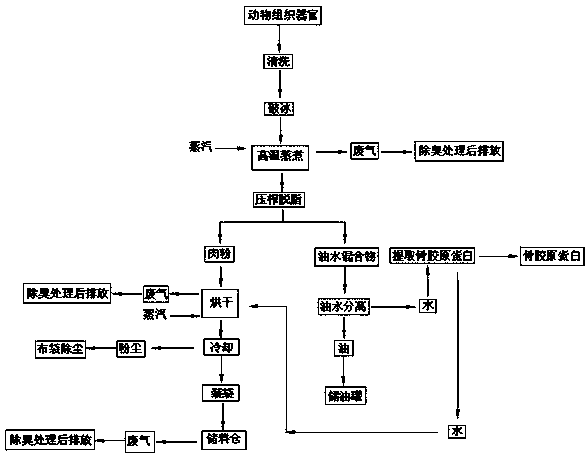

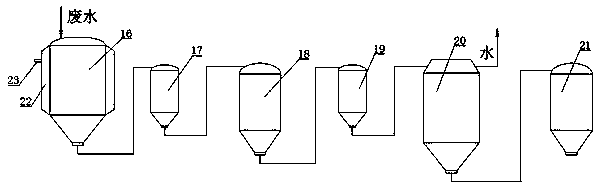

[0034] Such as figure 1 and 2 As shown, the present embodiment provides a kind of meat powder production equipment and process, including the high-pressure cleaner 2, ice breaker 3, grease tank 4 and double-screw press 5 sequentially connected by screw conveyor 1; One outlet of the press 5 is connected to a drying tank 6 through a screw conveyor 1, and the other outlet is connected to an oil-water separation centrifuge 7 through a screw conveyor 1; the drying tank 6 is connected to a cooling tank through a screw conveyor 1. machine 8; the cooling machine 8 is connected with a storage bin 9 through a screw conveyor 1; the cooling machine 8 is connected with a bag filter 10 through a pipeline; the bag filter 10 is provided with an induced draft fan 11; the oil-water The oil outlet of separation centrifuge 7 is connected with oil storage tank 12 by screw conveyor 1; The water is connected to the drying tank 6 through the water delivery pipe; the grease tank 4, the drying tank 6...

Embodiment 2

[0049] The difference between this embodiment and Example 1 is: S3: The animal tissues and organs after high-temperature cooking are subjected to three-stage degreasing in the double-screw press 5, the first-stage pressing pressure is 0.5 MPa, and the second-stage pressing pressure is 2.5 MPa , The three-stage squeezing pressure is 4.5MPa.

Embodiment 3

[0051] The difference between this embodiment and Example 1 is: S3: The animal tissues and organs after high-temperature cooking are subjected to three-stage degreasing in the twin-screw press 5, the first-stage pressing pressure is 1 MPa, the second-stage pressing pressure is 3 MPa, and the third-stage pressing pressure is 3 MPa. The extrusion pressure of the stage is 6MPa.

[0052] The water content of the meat powder after one squeeze is 21%-29%, while the water content of the meat powder after the three-stage squeeze of Example 1-3 is 9-16%. It can be seen that the animal tissues and organs after high-temperature cooking Three-stage degreasing, and the pressing pressure increases step by step, so that the degreasing of animal tissues and organs is more thorough, and the water content of the meat powder produced after degreasing will be lower, which is convenient for the subsequent drying process and improves production efficiency.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com