Oily fume purifier

An oil fume purifier and oil fume purification technology are applied in the fields of oil fume removal, chemical instruments and methods, and household heating. Avoid the effect of filter clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

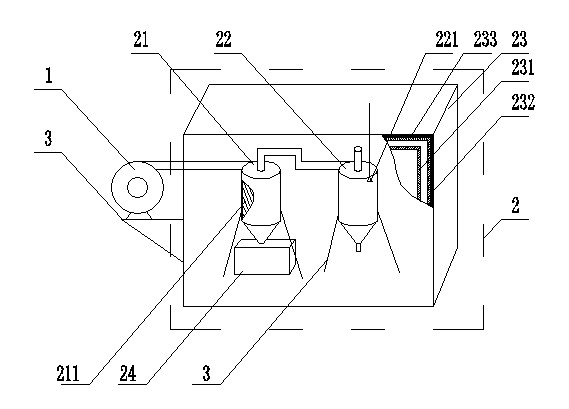

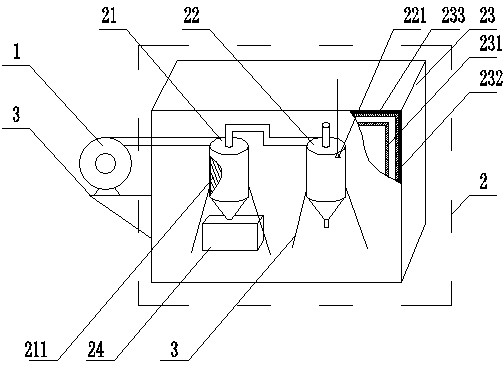

[0012] Below in conjunction with accompanying drawing and embodiment the technical solution of the present invention is further described:

[0013] like figure 1 As shown, the present invention provides a lampblack purifier, including a fan 1, a lampblack purification system 2 and a fixed frame 3, the fan 1 and the lampblack purification system 2 are fixed on the fixed frame 3, and the fan 1 is arranged at the entrance of the lampblack purification system 2 The oil fume purification system 2 includes two cyclone separators 21, 22 connected in series, a filter box 23 and a grease storage box 24, and the filter box 23 consists of two mutually nested activated carbon plate boxes 231, 232 and Sponge 233 is made up of, and sponge 233 is coated on the outside of activated carbon box 232, and filter box 23 wraps cyclone separator 21,22 and grease holding box 24, and the air inlet of first cyclone separator 21 is connected with blower fan 1 outlet, The gas outlet of the second cyclon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com