Composite enzyme preparation for fur degreasing and preparation method thereof

A compound enzyme preparation, fur technology, applied in leather degreasing, small raw hide/large raw hide/leather/fur treatment, small raw hide/large raw hide/leather hide/fur chemical treatment, etc. Hair and other problems, to achieve the effect of environmental cleanliness and friendliness, energy saving, and uniform degreasing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

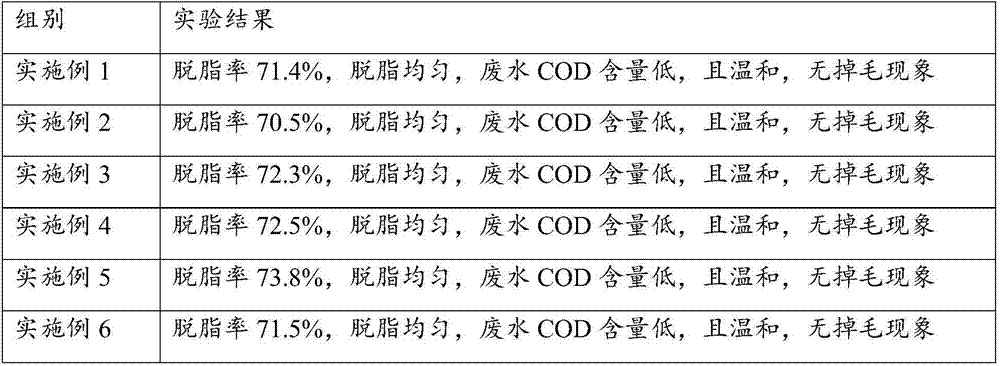

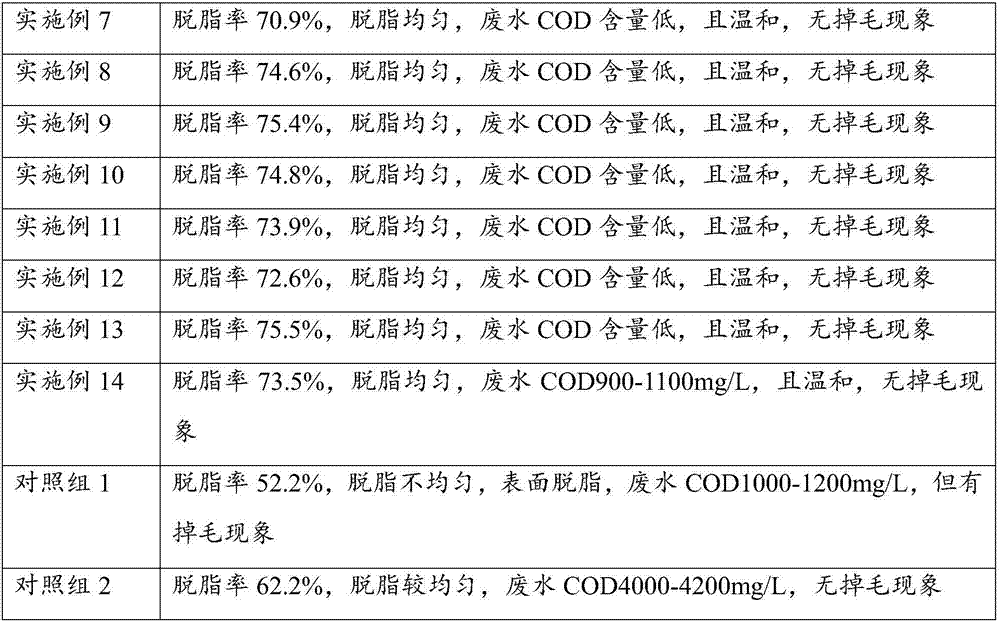

Examples

preparation example Construction

[0040] The preparation method of the fur degreasing compound enzyme preparation provided by the invention is simple and easy to implement, and is easy to produce in large quantities. The non-metal container can be plastic, porcelain and the like.

[0041] In order to prevent each raw material from reacting with the container itself and losing the activity of each raw material, further, the non-metallic container is an enamel reaction kettle.

Embodiment 1

[0043] The fur degreasing composite enzyme preparation provided by the present embodiment comprises the following components:

[0044] Neutral lipase 0.2kg, sodium tripolyphosphate 0.8kg, sodium pyrophosphate 0.5kg, calcium chloride 0.5kg, silicone polyether 0.4kg and sodium sulfate 5kg.

[0045] The preparation method of this fur degreasing compound enzyme preparation specifically comprises the following steps:

[0046] The raw materials are added into the enamel reaction kettle according to the weight ratio, mixed evenly, and discharged to obtain a white powdery product, which is the fur degreasing compound enzyme preparation.

Embodiment 2

[0048] The fur degreasing composite enzyme preparation provided by the present embodiment comprises the following components:

[0049] Neutral lipase 0.05kg, industrial pancreatin 0.05kg, sodium tripolyphosphate 1.2kg, polyvinylpyrrolidone 0.3kg, silicone polyether 0.4kg and sodium sulfate 6kg.

[0050]The preparation method of this fur degreasing composite enzyme preparation is the same as that in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com