Preparation of sheep placenta peptide

A preparation process, technology of sheep fetus, applied in food preparation, skin care preparations, medical preparations containing active ingredients, etc., can solve unsuitable large-scale industrial production, many technical parameters and control factors, and affect the physical and chemical indicators of finished products and other problems, to achieve the effect of convenient production, low cost and short cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Embodiment 1: prepare sheep fetal peptide by the method of the present invention

[0023] Wash 100 kilograms of fresh sheep placenta raw materials with water, remove fetal membranes, large blood vessels, connective tissue, etc., mince them with a meat grinder, add 100 kilograms of normal saline to the colloid mill to grind the minced meat into a homogenate; use 8000 Transfer / centrifuge for 15 minutes to remove impurities, collect the supernatant; inject the supernatant into the pre-prepared D-101 macroporous resin column for saturated adsorption, wash the resin column twice with 50% ethanol, and separate the polypeptide from the column Sheep fetus extract; sheep fetus extract is concentrated under reduced pressure at 45°C to a density of 1.05; the concentrated solution is pumped into a spray drying tower, the inlet air temperature is 120°C, the outlet air temperature is 50°C, and cooled to room temperature to obtain solid sheep fetus Peptide powder, weighing 8.8 kg, ste...

Embodiment 2

[0026] Embodiment 2: the comparative experiment of spray-drying process and the method of the present invention not combined with macroporous resin adsorption

[0027] Wash 100 kilograms of fresh sheep placenta raw materials with water, remove fetal membranes, large blood vessels, connective tissue, etc., mince them with a meat grinder, add 100 kilograms of normal saline to the colloid mill to grind the minced meat into a homogenate; use 8000 Rotate / separate the centrifuge for 15 minutes to remove impurities and collect the supernatant; the supernatant is concentrated to a density of 1.05 by vacuum distillation at 45°C; the concentrate is pumped into the spray drying tower, the inlet air temperature is 120°C, and the outlet air temperature is 50°C , cooled to room temperature to obtain solid sheep fetal peptide powder, weighing 9.3 kg, sterilized, packaged, inspected, and put into storage.

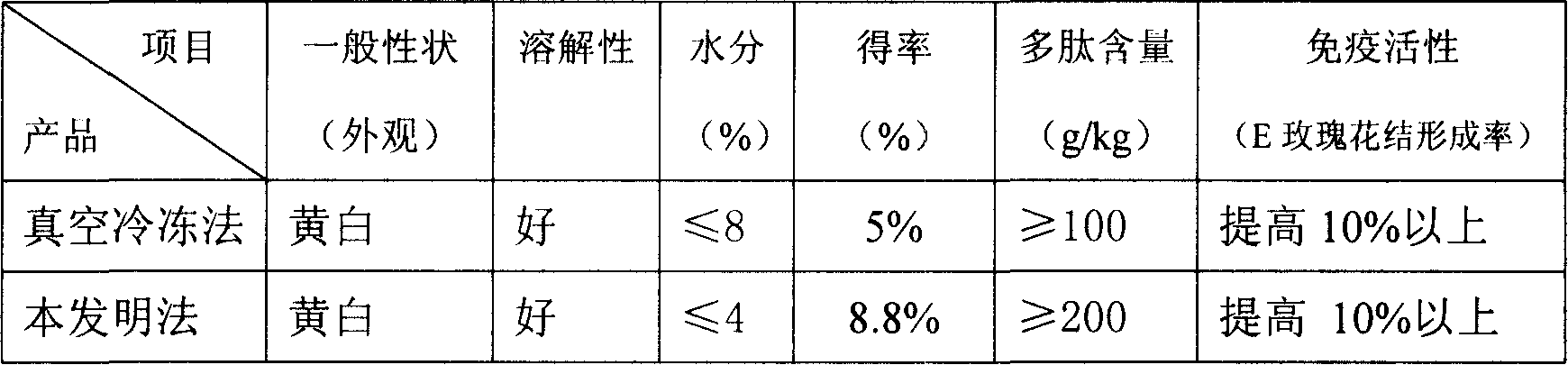

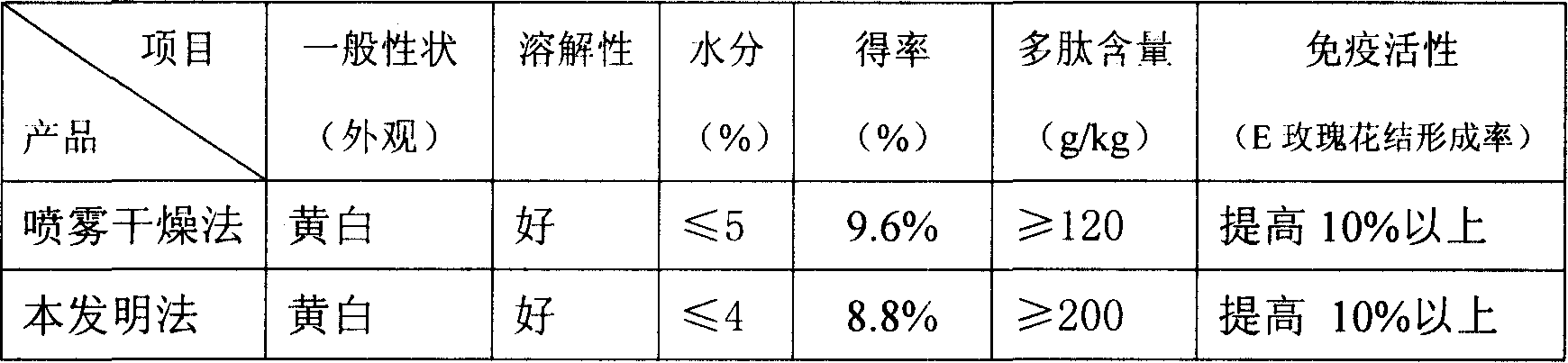

[0028] The inventive method compares as follows with the spray-drying process gained p...

Embodiment 3

[0031] Get 50 grams of sheep fetal peptide powder prepared by embodiment 1 or 2, prepare 1000 hard capsules according to the following raw material formula:

[0032] Sheep Fetal Peptide 50g

[0033] Glucose powder 230g

[0034] Dextrin 100g

[0036] Take 50 grams of the above-mentioned sheep fetal peptide, 250 grams of glucose powder, 100 grams of dextrin and 20 grams of magnesium stearate, mix them evenly, pass through a 80-mesh sieve, granulate with a dry granulator, granulate with a 60-mesh sieve, and fill the capsules , that is.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com