Hammer type dynamically and cyclically screening-crushing machine

A dynamic circulation and crusher technology, applied in grain processing, etc., can solve problems such as easy blockage of screen holes, achieve a large adjustment range, reduce the difficulty of construction and equipment maintenance, and avoid easy wear and tear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail below in conjunction with specific examples, but the implementation of the present invention is not limited thereto.

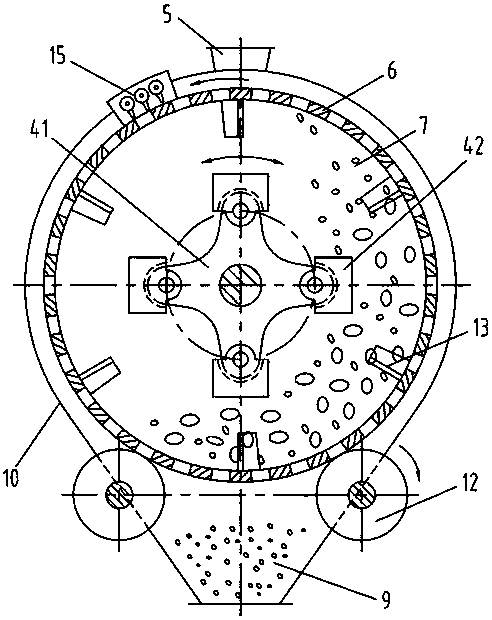

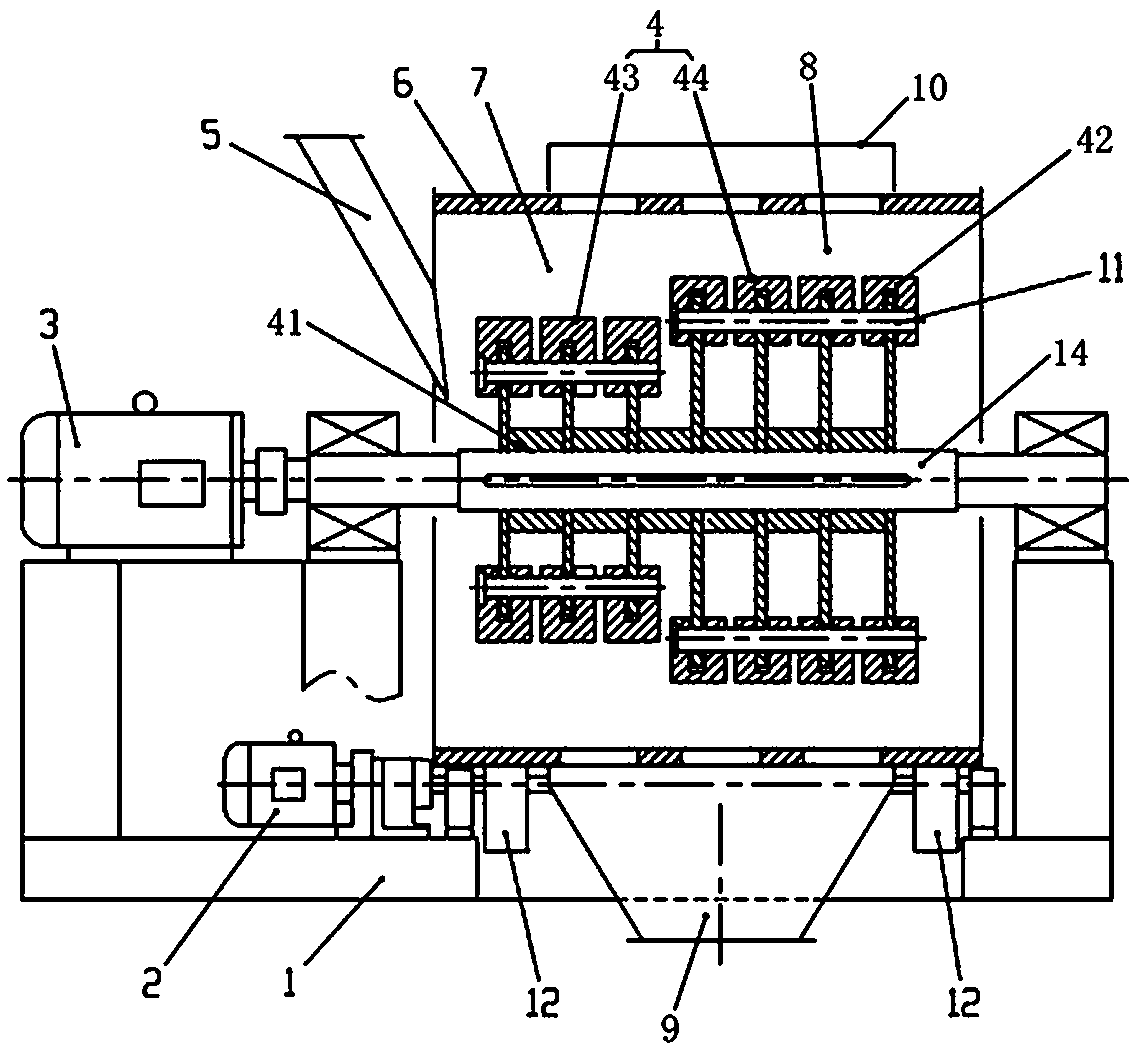

[0030] Such as Figure 1-Figure 5 As shown, the hammer-type dynamic circulation screening crusher of the present invention includes a base 1, a feed port 5, a discharge port 9, a screening drum 6 and a hammer rotor group 4, and the hammer rotor group 4 is arranged on the screen Inside the drum 6 and coaxial with the screening drum 6 .

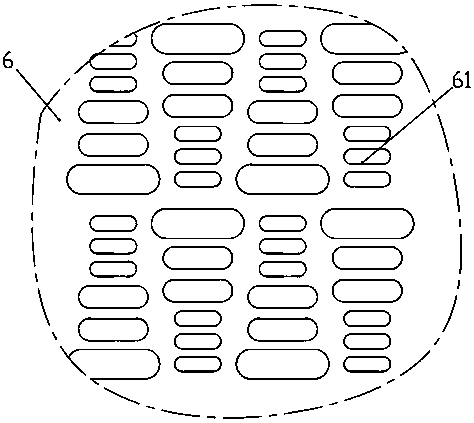

[0031] The sieve drum 6 is provided with several strip-shaped sieve holes 61, the width of each sieve hole 61 is 5-30mm, and the size and distribution rate of the sieve holes 61 are consistent with the material particle size distribution curve required by the process. Finally, several sieve holes of different sizes will be formed on the roller, such as image 3 shown. The inner wall of the screening drum 6 is also welded with lifting plates 13 which are distrib...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com