Blasting method for treatment of gob

A technology of gobs and blastholes, which is applied in blasting and other directions, can solve the problems of small rock blasting vibration and incomplete collapse of gobs, so as to achieve complete rock collapse, improve work safety and stripping efficiency, and have large vibration force Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

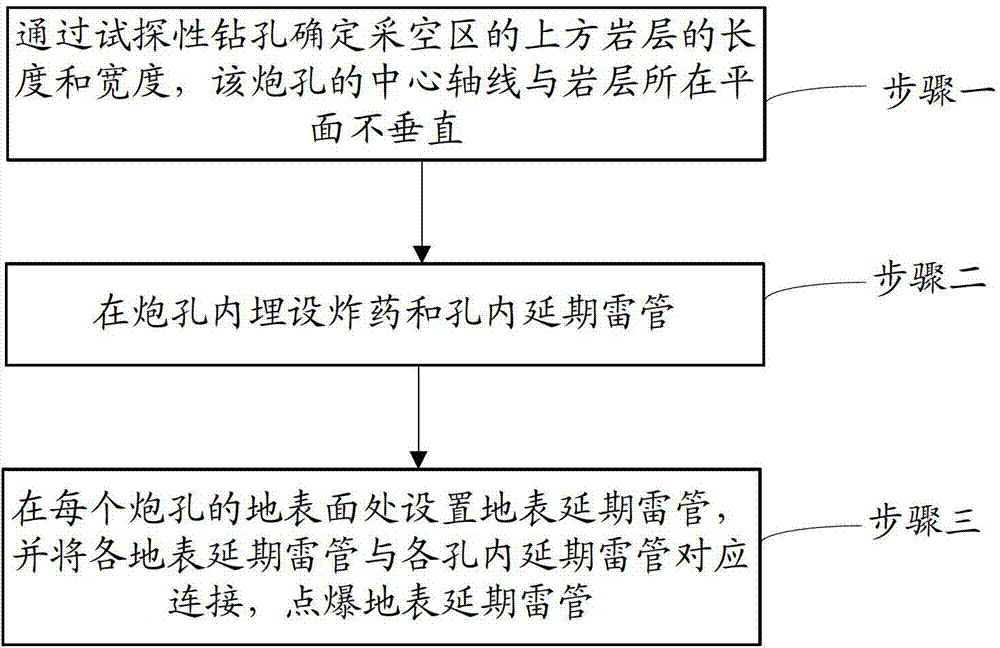

[0033] figure 1 It is a schematic flow chart of the blasting method for processing goafs provided by the embodiment of the present invention. The embodiment of the present invention provides a blasting method for processing goafs, which includes the following steps:

[0034] Step 1. Determine the length and width of the rock strata above the gob by tentatively drilling the blast holes, the central axis of the blast holes is not perpendicular to the plane where the rock strata are located.

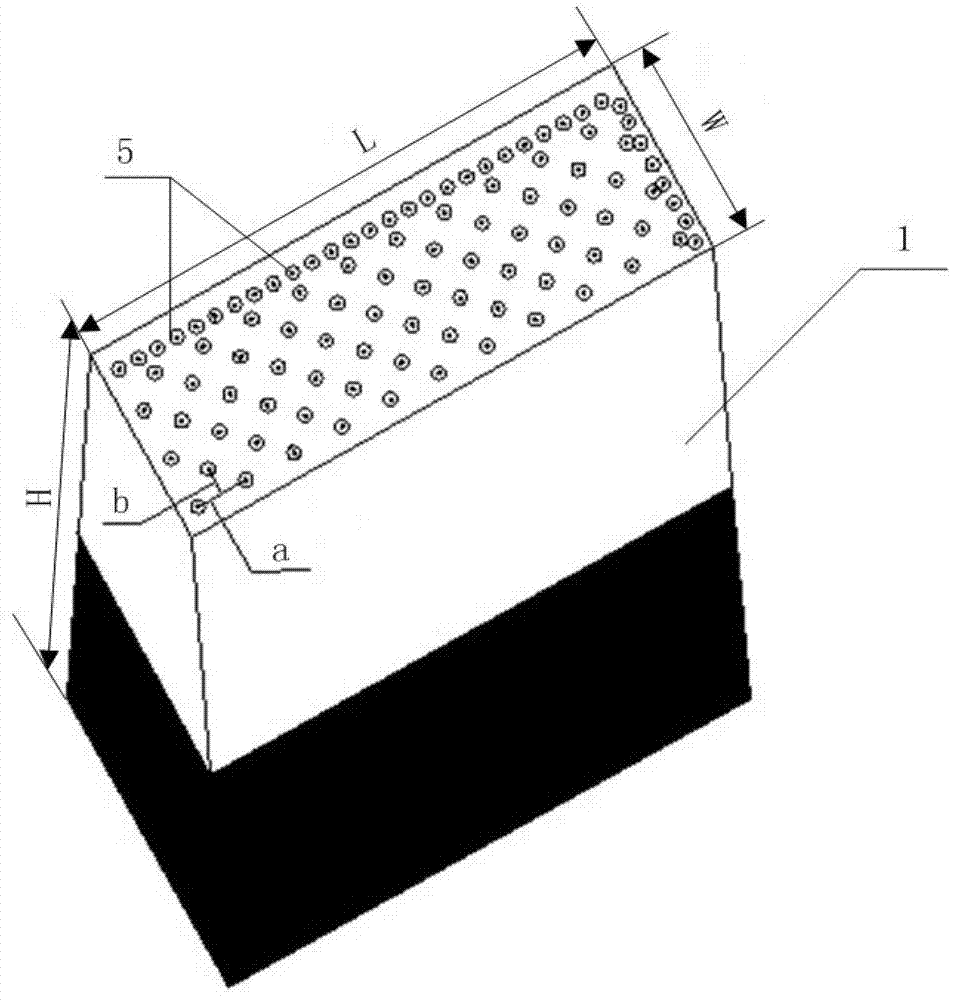

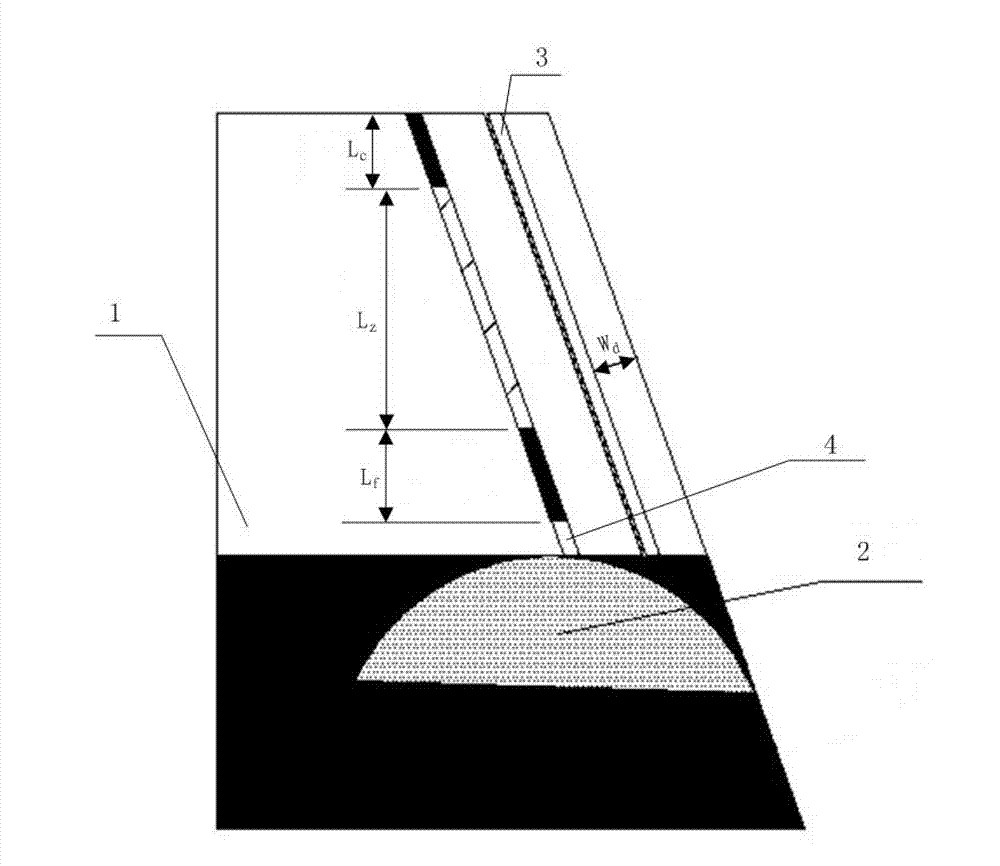

[0035] figure 2 It is a schematic diagram of the structure of the rock formation above the goaf, such as figure 2 As shown, above the determined goaf position, the precise width and length of the goaf can be found through exploratory drilling, thereby determining the parameters of the blasting area, that is, the length L of the rock formation 1 above the goaf and width W, the range enclosed by length L and width W is taken as the area to be blasted above the goaf. The specific operatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com